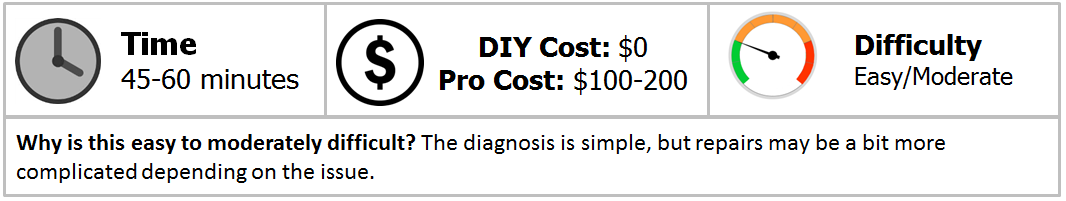

Jeep Wrangler JK: Suspension Noise Diagnostic Guide

There are several suspension components causing noise in your Jeep. Some are normal, and some can be indicative of a real problem. Learn how to self-diagnose before tearing your JK apart.

This article applies to the Jeep Wrangler JK (2007-Present).

Some of the most common complaints among JK owners in regards to their suspension is some noisy and annoying squeaks, pops, clunks or squeals from somewhere under the body. A noisy suspension is not only irritating, it could also be a sign that something isn't quite right and has the potential to cause additional problems if left untreated. You don't have to live with an annoying noise from your suspension and you shouldn't either. Use this diagnostic guide to help pinpoint where that noise is coming from and what you need to do to get it fixed. This may be a job for the DIYer, or the big guns may need to be called in depending upon the issue. The important thing is that you took the time to pinpoint the problem and know what needs to be done to get the problem corrected. Use this guide to determine if you should take her in, or save a ton of money doing this work yourself.

Materials Needed

- Floor jack and jack stands

- Crow bar, pry bar or breaker bar

- 3/8" drive ratchet and various sockets

- Assistant

Step 1 – Check your bushings

They could be cracked or brittle and causing direct metal-on-metal contact, or very dirty and devoid of lubricant.

The bushings at the end of your control arm are the more common causes of noisy suspensions. If the bushings are in good working order, they likely just need either to be re-torqued or need a good cleaning and lubing. Try over-tightening and torquing to at least 125 pounds or more to see if that solves the noisy problem. If it still persists, then we need to take apart the bushings and clean each component real well. The metal washers and pieces do well in brake fluid. Get them nice and clean, then apply a very liberal amount of waterproof marine lubricant to all surfaces and re-assemble. Make sure you torque them to at least 125 pounds. This should take care of that annoying squeak for many more miles.

If you are hearing a clunking noise, it could be your steering box.

Step 2 – Check steering box for clunking noise

You may have some play in the selector shafts.

Prior to the 2009 model year, Jeep used a steering box that has had many problems with clunking noise from too much wear going on with the selector shafts. In '09 they upgraded to a heavy duty steering box. While you may take yours to the dealership, or a shop, to have a new box installed or to have the components repaired, the problem will likely return if they do not replace it with the upgraded HD version.

- Have someone sit in your Jeep to turn the steering wheel from full lock to full lock left to right and feel for the clunk.

- The clunk should feel more intense as you move toward the Pitman arm and selector shaft.

- Have your assistant make small, sharper left and right turns much faster.

- You will likely see some play in the selector shaft. There should be none. If the play in that shaft is very much greater than 1/8", you must get this remedied ASAP.

Figure 2. Check the sector shaft in the steering box for any side to side play.

Figure 3. Aside from a complete rebuild, installing a sector shaft brace such as this one from Synergy may help resolve the clunking noise in your steering box.

If you don't have a clunk from the steering box, but a general rattling noise from somewhere under the Jeep, it could be your joints.

Step 3 – Check ball joints and U-joints

The bushings could be bad or need lubricated.

The ball joints could potentially be bad, but it is more likely the bushings attached. Check them for proper torque (125 pounds). You may even wish to over-tighten them.

- Raise one side of the front end and put some axle weight onto a jack stand.

- Use a crowbar or other heavy pipe to lift the tire up and down to look for play in the lower ball joints.

- Grab the top as well as bottom of the tire to move it in and out to check for play in the upper ball joints.

- They should not have any side to side or up and down play more than .050 to .060". If they do, replace the joints.

- If the play is within that range, check on the bushing and make sure they are tight as well as clean; use some marine grade waterproof lubricant.

- If they check out and the noise persists, check the U-joints, which is a lot more labor intensive.

- Remove the tire, brakes and wheel hub.

- Pull the axle shaft, remove the hub from the shaft, then replace the U-joints with high grade, heavy duty U-joints, and make sure to torque them to specifications.

Figure 4. The rattling noise could be from bad bushing in your ball joints.

Figure 5. If the ball joints and bushings check out fine, take a close look at the U-joints and replace them if needed.

If you are hearing a slight creaking or popping noise while flexing, it is likely normal.

Step 4 – Check controls arms or shock mounts rubbing against frame rails

Some rubbing while off-road driving will be normal.

While off-roading, some creaking noise is going to be normal, especially with lift kits installed. While this may be disconcerting at first, you will probably get used to it. Off-roading will cause some flexing of metal parts that normally wouldn't flex at all. You may see some rub marks at the shock tower or on the coils. This should be considered normal wear, but for peace of mind, have it looked at by a pro who is an expert in installing lift kits and off-road packages to be sure.

If you are still hearing a clunking noise that wasn't resolved with prior checks, look to the rear of your Jeep.

Step 5 – Check rear control arm bushings and track bar

The rear control arm bushings may have gone bad or the snap ring broken, which can cause a clunking noise.

The rear control arm is prone to breaking snap rings, which can cause the metal-on-metal slapping noise. This can also happen if the JK track bar or jam nut is hitting the springs. This happens often if the wedges have been removed or missing.

Related Discussions

- What Kind of Grease to Use on Polyurethane Bushings? - JK-Forum.com

- WARNING Please Read - JEEP JK Steering GEAR BOXES are Cause for the Clunk - JK-Forum.com

- Attention All Clunky Steering People - JK-Forum.com

- Suspension Noise/Rattle on Bumpy Roads - JK-Forum.com

- Creaking Noises in Suspension When Flexed, Ideas? - JK-Forum.com

- A Clunking Noise - JK-Forum.com