Jeep Wrangler JK: How to Replace Serpentine Belt

You’re about to take your Jeep on a trip to the middle of nowhere, but recently you noticed some fraying along the edges of your Jeep’s serpentine drive belt. It’s probably a good idea to change the belt before your journey, and not have to deal with the consequences of it failing on a logging trail.

This article applies to the Jeep Wrangler JK (2007-Present).

Serpentine belts use the crankshaft pulley/harmonic balancer to drive the alternator, water pump, air conditioner, and power steering. If your drive belt fails, your Jeep won’t be drive-able in only a few minutes.

Serpentine belts typically can last from between 45,000 and 75,000 miles, or three to five years of driving, for passenger cars. But off-road use and hauling heavy loads, not to mention taxing workouts like snow plowing, can shorten their lives significantly. As a belt wears, it may emit a squeaking or chirping noise and a badly-worn multi-grooved belt can end up splitting apart at the grooves, or simply breaking in two.

Drive belts are made of a durable, rubber-like compound that over the years has become extremely durable. But from the manufacturer’s point of view, in addition to wearability, keeping these belts as short as possible is also very desirable. This is because a shorter belt stretches less and can reduce friction because it requires fewer idler pulleys along its path. Besides designing engines with the accessories clustered closer together, eliminating accessories from requiring drive belt connection is also being done. This is also one reason why many auto manufacturers have already switched, or might soon switch, to electric power steering (EPS) systems in order to eliminate the belt connection to a vane pump.

Replacing the serpentine belt in a Jeep Wrangler JK is really only challenging because the space can be so tight, especially, as we’ll see, in later JK models with the 3.6L Pentastar V6. Another issue is the fact that the JK’s belt tensioner looks and operates very differently, depending on which V6 engine you’re working on.

Materials Needed

- Socket set with 3/8" and 1/2" drive stud

- Belt removal tool ($16-20), or equivalent (long 1/2" breaker bar with 3/8" and 1/2" connection on the end; optional)

From its introduction in 2007 to 2011, the Jeep Wrangler JK used the 3.8L EGH V6 engine. For 2007, this engine produced 215 hp and 245 lb/ft (332 N·m) of torque. In 2008 this engine was modified, some might say downgraded, resulting in it producing 197 hp and 230 lb/ft (312 N·m) of torque—or 15 less hp, and 15 less lb-ft (20 N-m) of torque than its first iteration.

In 2012, the JK switched over to the 3.6L Pentastar V6, which was lighter (it used an aluminum block) and smaller, combustion-chamber-size-wise. However, it also offered 285 hp (213 kW) and 265 lb/ft of torque, 70 more hp, and 20 more lb/ft (27 N-m) of torque than the 2007 engine. Also, the 3.6L V6 serpentine belt tensioner design is significantly different from the 3.8L V6.

Step 1 – Prep the Jeep

Put the Jeep in park and the emergency brake on. It’s always a good idea to disconnect the battery. Have your new replacement serpentine drive belt handy.

Step 2 – Remove cold air dam intake assembly (3.6L Pentastar V6)

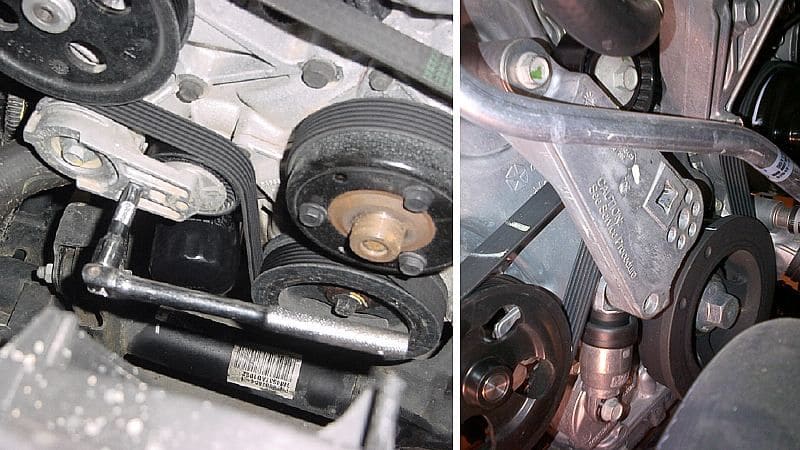

On the 2.8L EGH V6, there should be enough room to access the drive belt (see Figure 2).

However, with the 3.6L Pentastar V6, the space between the front of the engine and radiator fan is noticeably very tight, as shown below. For this reason, you’ll need to carefully remove the cold air dam intake assembly back to the throttle body to access the serpentine drive belt.

Step 3 – Remove tension on the serpentine belt

On the 3.8L V6, the drive belt tensioner is composed of a pulley and a swing arm. A 3/8-inch socket wrench is sufficient to release the tension on the drive belt. Insert the socket wrench drive shaft into the center square hole, and turn the wrench clockwise. Pull the belt off the smooth belt tensioner pulley—this operation can, in fact, all be done with one hand!

For the 3.6L V6, the belt tensioner is larger and also includes a small hydraulic cylinder that acts as a dampener to help keep the tensioner from bouncing and chattering during power surges. A 1/2-inch, long socket wrench is needed to remove tension on the drive belt. However, the amount of pressure to move the swing arm on this engine is greater because of the inclusion of the hydraulic cylinder. For this reason, some use a breaker bar with a 1/2-inch socket end. Others use a socket wrench with a length of plastic pipe over the handle to extend its length. There are also special tools available, such as this serpentine belt tool (in Figure 6), priced at around $16 to $20.

Note that turning the tensioner with the wrench should be done slowly, as the cylinder restricts movement. On this engine, removing the tension on the belt and removing the belt is made much easier using two people—one turning and holding the wrench, the other reaching in to slide the belt off the roller. With only one person, once the breaker bar is turned enough to remove tension on the belt, the bar can be tied off (a ratchet strap can work well for this), or taped in place to allow the easy removal of the belt.

Feed the belt off all the accessories and idlers, then remove it.

Step 4 – Replace serpentine belt with a new one

Make sure you have purchased the right serpentine belt for your vehicle. A main difference in belt length is for vehicles that don’t have an air conditioner.

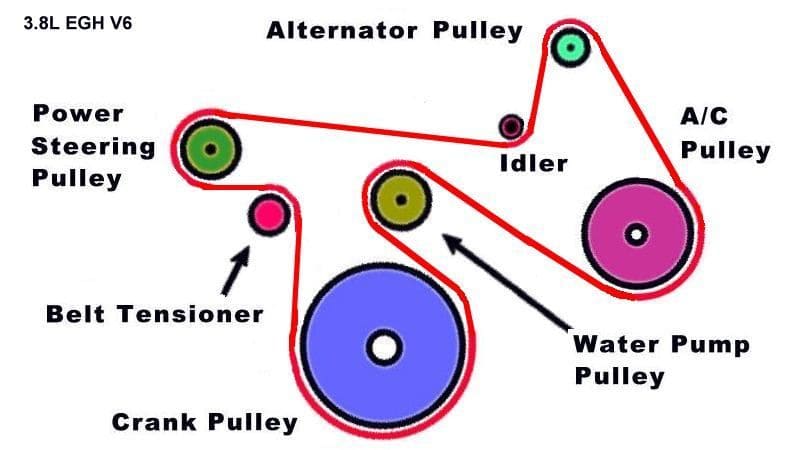

The diagram below shows the path the serpentine belt takes in the 3.8L V6 engine. This belt, for vehicles with AC, has six ribs and is 90.03 inches (2,287mm) in length.

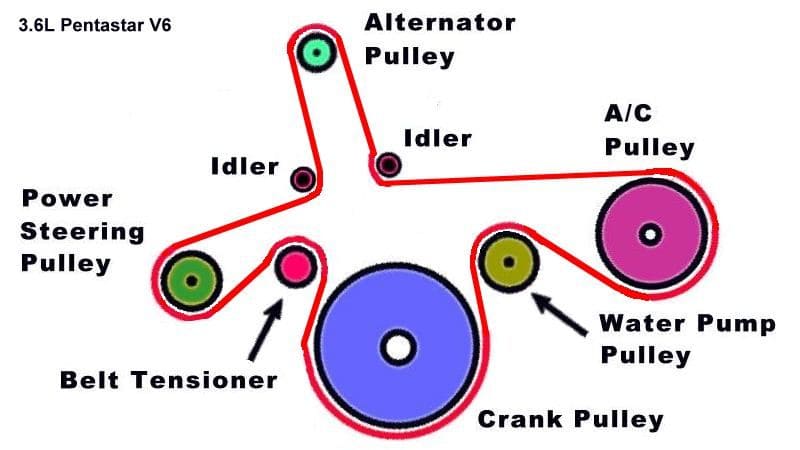

The diagram below shows the path the serpentine belt takes in the 3.6L V6 engine. This belt, including AC, has six ribs and is a bit shorter than the 3.8L engine, 87.57 inches (2,224mm).

Replacing the serpentine drive belt is done by putting downward pressure on the belt tensioner while routing the belt in place, making sure all the grooves are fully engaged and then slipping the belt over an un-grooved pulley. An unproved pulley better accommodates sliding the belt laterally across it—many use the water pump pulley, or any more-convenient idler pulley to accomplish this.

Related Discussions

- Changing Serpentine Belt - JK-Forum.com

- Serpentine Belt Replacement - JK-Forum.com