OEM Ball Joint Study Results

#1

I recently received some old ball joints from Hellbound13. Thanks Hellbound!

I cleaned them up and dissected them to see how they are made, how they function, and determine if they can be made grease-able.

This is what I came up with:

The lower ball joint is designed to bend, rotate, and have no axial or radial movement. They come from the factory with no grease fitting. An inspection of the internal parts revealed it is designed to be grease-able. The amount of grease found in the ball joint was no more than what would be called "butter lubricated" during assembly.

The plastic socket liner has a hole in the top, and grease grooves going down the inside where the ball resides.. The very top of the ball is flat, making a nice grease reservoir. The top of the ball joint body can be drilled in the center without risk of damage, and tapped, providing suction is used to keep the filings from entering the joint during each operation.

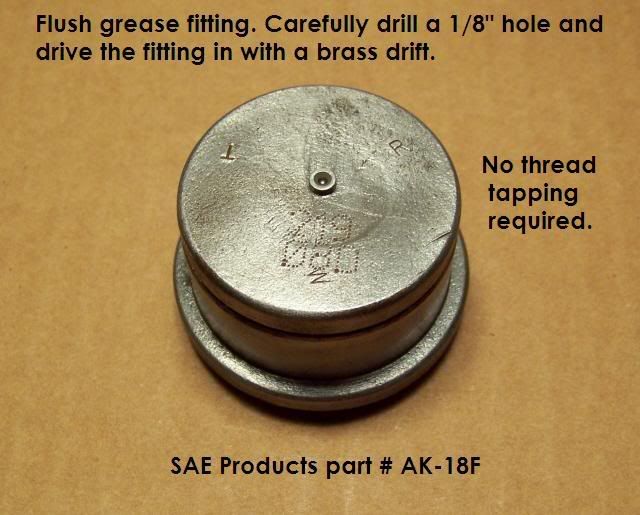

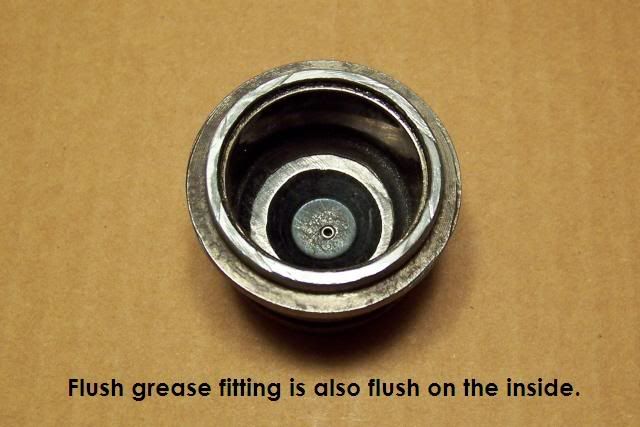

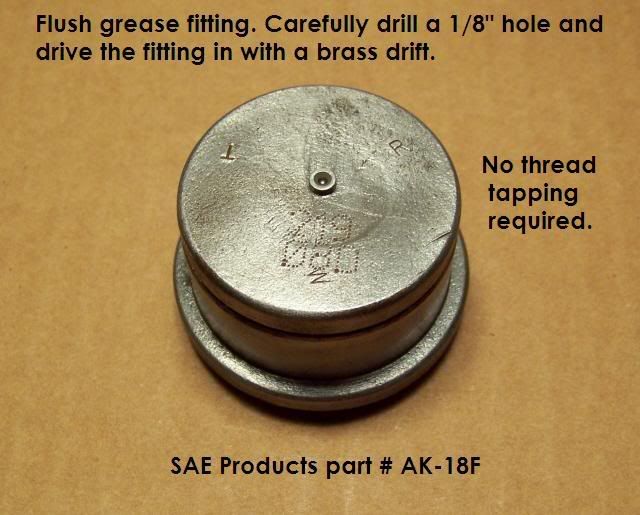

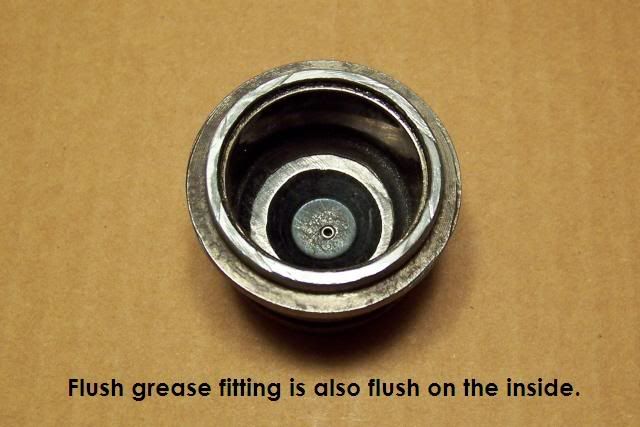

There isn't room for a regular zerk fitting because the u-joint yokes will hit. At least that's the case on my Rubicon axle. A flush fitting would work. Here is one source: h**p://www.saeproducts.com/flush-grease-fitting-AK18F.html

Installing a grease fitting in this joint, on the vehicle, would be difficult. I would recommend doing it on the new joint, before installation.

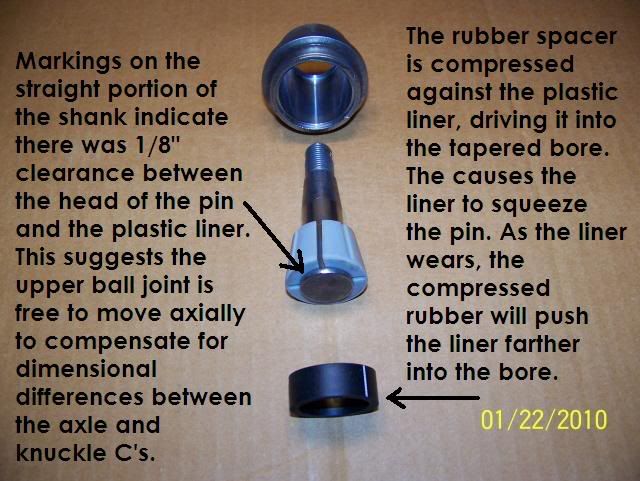

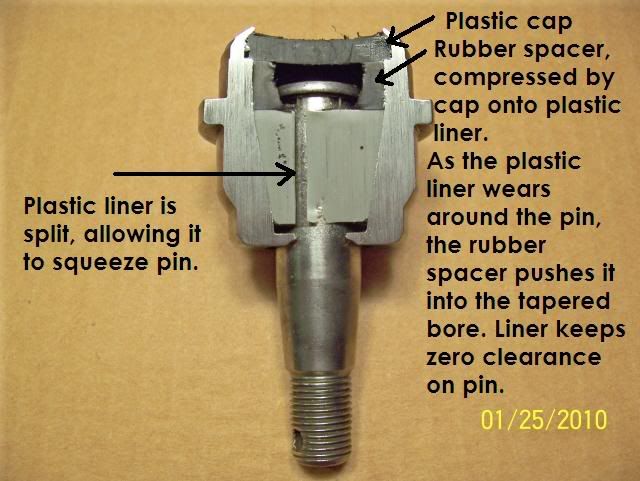

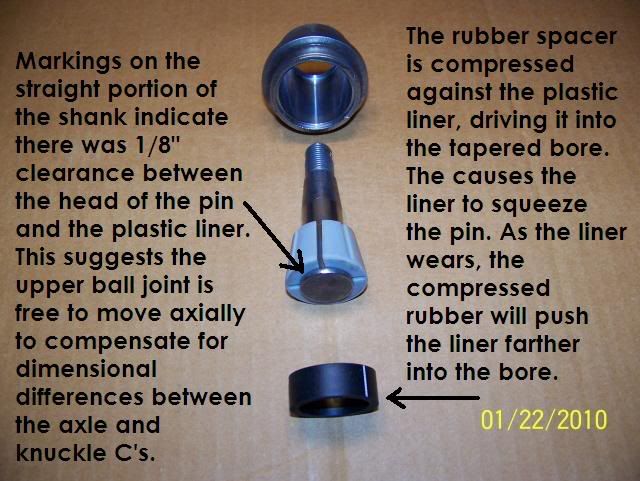

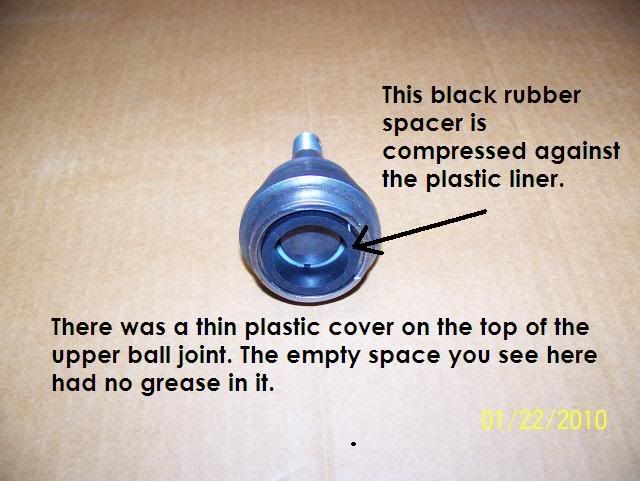

The upper joint does not bend. It can rotate and is designed to allow for axial movement, and no radial movement.

The amount of grease found in the ball joint was no more than what would be called "butter lubricated" during assembly.

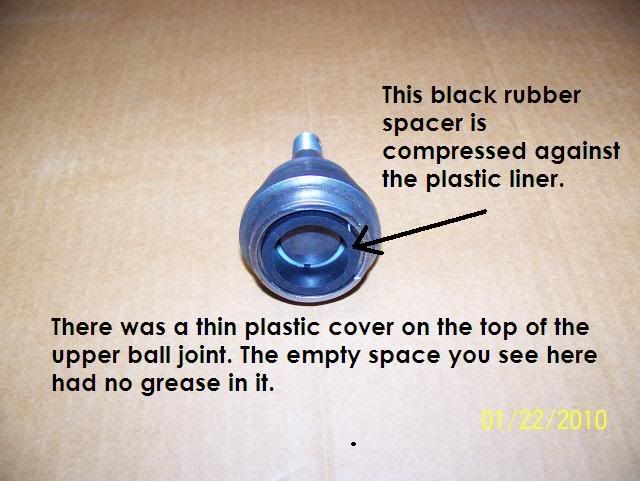

Installing a grease fitting in the upper joint is not recommended, as the pressure would likely blow out the thin plastic cover on the top.

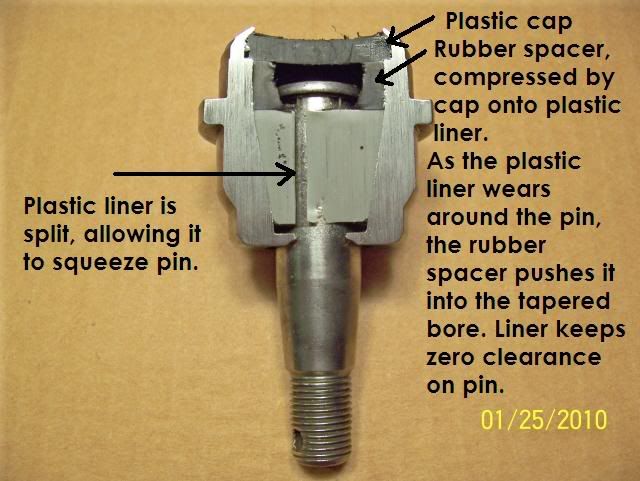

The plastic liner in the joint is designed to make up for radial wear, for a while, at least.

So, installing grease fittings in only the lower ball joints may sill extend the lives of all four ball joints.

I cleaned them up and dissected them to see how they are made, how they function, and determine if they can be made grease-able.

This is what I came up with:

The lower ball joint is designed to bend, rotate, and have no axial or radial movement. They come from the factory with no grease fitting. An inspection of the internal parts revealed it is designed to be grease-able. The amount of grease found in the ball joint was no more than what would be called "butter lubricated" during assembly.

The plastic socket liner has a hole in the top, and grease grooves going down the inside where the ball resides.. The very top of the ball is flat, making a nice grease reservoir. The top of the ball joint body can be drilled in the center without risk of damage, and tapped, providing suction is used to keep the filings from entering the joint during each operation.

There isn't room for a regular zerk fitting because the u-joint yokes will hit. At least that's the case on my Rubicon axle. A flush fitting would work. Here is one source: h**p://www.saeproducts.com/flush-grease-fitting-AK18F.html

Installing a grease fitting in this joint, on the vehicle, would be difficult. I would recommend doing it on the new joint, before installation.

The upper joint does not bend. It can rotate and is designed to allow for axial movement, and no radial movement.

The amount of grease found in the ball joint was no more than what would be called "butter lubricated" during assembly.

Installing a grease fitting in the upper joint is not recommended, as the pressure would likely blow out the thin plastic cover on the top.

The plastic liner in the joint is designed to make up for radial wear, for a while, at least.

So, installing grease fittings in only the lower ball joints may sill extend the lives of all four ball joints.

Last edited by ronjenx; 12-12-2012 at 12:56 PM.

#3

Dude really nice write up! Thanks for taking the time to document the whole process...definitely gonna keep this thread as we'll all need to replace them sooner rather than later and this will allow us to extend the life!

#5

Holy crap! I can not believe how you cleaned up those ball joints. They looked like dog doo when I sent em to you!

Ronjenx,

I am wondering based on your write up if the Crowns then would be able to take zerk fittings. They appear the same as the mopar, however the top ball joint has metal on top not plastic, so it might be do able.

Wish I had known this before installing the new ball joints. The lowers I sent you seemed worse than the uppers.

Ronjenx,

I am wondering based on your write up if the Crowns then would be able to take zerk fittings. They appear the same as the mopar, however the top ball joint has metal on top not plastic, so it might be do able.

Wish I had known this before installing the new ball joints. The lowers I sent you seemed worse than the uppers.

#6

Holy crap! I can not believe how you cleaned up those ball joints. They looked like dog doo when I sent em to you!

Ronjenx,

I am wondering based on your write up if the Crowns then would be able to take zerk fittings. They appear the same as the mopar, however the top ball joint has metal on top not plastic, so it might be do able.

Wish I had known this before installing the new ball joints. The lowers I sent you seemed worse than the uppers.

Ronjenx,

I am wondering based on your write up if the Crowns then would be able to take zerk fittings. They appear the same as the mopar, however the top ball joint has metal on top not plastic, so it might be do able.

Wish I had known this before installing the new ball joints. The lowers I sent you seemed worse than the uppers.

Just kidding.

Just kidding.I don't think there is a need to grease the OEM upper ball joints. It looks like they are designed to automatically compensate for radial wear. If the Crown ball joints are made the same way, I would say the same for them.

You said the top covers on the Crowns are metal. Probably thin metal. I bet they are crimped around the edges like the OEM upper joints.

A grease gun is capable of applying thousands of psi inside a joint. Enough to blow out even the Crown metal cover, given its surface area.

My conclusion is there is no reason to grease the OEM upper joint on the JK, and attempting to do so could damage it.

Last edited by ronjenx; 01-22-2010 at 11:03 PM.

#7

Take your new Crowns out and send them to me.  Just kidding.

Just kidding.

I don't think there is a need to grease the OEM upper ball joints. It looks like they are designed to automatically compensate for radial wear. If the Crown ball joints are made the same way, I would say the same for them.

You said the top cover on the Crowns are metal. Probably thin metal. I bet they are crimped around the edges like the OEM upper joints.

A grease gun is capable of applying thousands of psi inside a joint. Enough to blow out even the Crown metal cover, given its surface area.

My conclusion is there is no reason to grease the upper joint on the JK, and attempting to could damage it.

Just kidding.

Just kidding.I don't think there is a need to grease the OEM upper ball joints. It looks like they are designed to automatically compensate for radial wear. If the Crown ball joints are made the same way, I would say the same for them.

You said the top cover on the Crowns are metal. Probably thin metal. I bet they are crimped around the edges like the OEM upper joints.

A grease gun is capable of applying thousands of psi inside a joint. Enough to blow out even the Crown metal cover, given its surface area.

My conclusion is there is no reason to grease the upper joint on the JK, and attempting to could damage it.

Trending Topics

#8