No CEL - limp mode no issues before 4,000 rpm randomly

#11

Looking at this again, it is odd that there are no codes and leads me to believe its mechanical and not electrical. i dont think the cam solenoids are bad or the connection is cut (ie the wores melted thoriugh) if they were, you would most def get codes. it sounds like the solenoid is stuck, and not engaging the oil control valve to teh high position. the fact that you had a rocker replaced adn this started is also not a coincidence. im learning toward the oil control valves are not opening and pushing the cam to the high position. like i said it is odd there are no codes, the camshaft position sensor sits on the back side of the valve covers adn those are incredibly sensitive. and if anything is awry, you dash will light up immediately. if they changed the rocker, they had to pull the cover, oil control valves and cam shafts. if timign was off, the cps was bad or anything electrical was off, you would get codes adn lights and rough idle, immediately. one thing i thought of is that the oil control valves are incredibly sensitive to magnets. it is even stamped on the front of them to not set them anywhere near a magnet. maybe, just maybe whoever took them apart set them in a magnetic tray (shit happens) and the oil control valves are roasted and everything electronic thinks everything is okay, thought the valves are not opening and movign the camshaft into the high rpm position and the cps is not registering the movement and keeping rpm low. i am not expert in the electrical punch list on the the jk and what system checks and balances the vvt system. though everyhign you have shared so far points to a roached oil control valve. ???

The following users liked this post:

Hiccup (07-05-2021)

#12

Looking at this again, it is odd that there are no codes and leads me to believe its mechanical and not electrical. i dont think the cam solenoids are bad or the connection is cut (ie the wores melted thoriugh) if they were, you would most def get codes. it sounds like the solenoid is stuck, and not engaging the oil control valve to teh high position. the fact that you had a rocker replaced adn this started is also not a coincidence. im learning toward the oil control valves are not opening and pushing the cam to the high position. like i said it is odd there are no codes, the camshaft position sensor sits on the back side of the valve covers adn those are incredibly sensitive. and if anything is awry, you dash will light up immediately. if they changed the rocker, they had to pull the cover, oil control valves and cam shafts. if timign was off, the cps was bad or anything electrical was off, you would get codes adn lights and rough idle, immediately. one thing i thought of is that the oil control valves are incredibly sensitive to magnets. it is even stamped on the front of them to not set them anywhere near a magnet. maybe, just maybe whoever took them apart set them in a magnetic tray (shit happens) and the oil control valves are roasted and everything electronic thinks everything is okay, thought the valves are not opening and movign the camshaft into the high rpm position and the cps is not registering the movement and keeping rpm low. i am not expert in the electrical punch list on the the jk and what system checks and balances the vvt system. though everyhign you have shared so far points to a roached oil control valve. ???

https://www.quadratec.com/p/crown-au...r-jk-5184150AF

Last edited by djdowney; 07-01-2021 at 11:31 AM.

The following users liked this post:

bujinkantd (01-10-2022)

#13

Thatd be the part. There is a camshaft sprocket that also can't go anywhere near a magnet. Like i said, its a guess at best. I posted a link to a cooy of the 2013 Field Service Manual. Its a 7200 page technical guide on how to work on a jeep. Its for a 2013 but they are the same except for the oil cooler on 14+. This may help as it is detailed as what. Youll see when you open it. Itll give you detailed insight into the inner workings of the engine at least.

https://drive.google.com/file/d/1GGO...?usp=drive_web

https://drive.google.com/file/d/1GGO...?usp=drive_web

The following users liked this post:

Hiccup (07-05-2021)

#14

Thatd be the part. There is a camshaft sprocket that also can't go anywhere near a magnet. Like i said, its a guess at best. I posted a link to a cooy of the 2013 Field Service Manual. Its a 7200 page technical guide on how to work on a jeep. Its for a 2013 but they are the same except for the oil cooler on 14+. This may help as it is detailed as what. Youll see when you open it. Itll give you detailed insight into the inner workings of the engine at least.

https://drive.google.com/file/d/1GGO...?usp=drive_web

https://drive.google.com/file/d/1GGO...?usp=drive_web

I appreciate your help, thank you.

The following 2 users liked this post by djdowney:

bujinkantd (01-10-2022),

Marcus Byrd (05-24-2022)

#15

Hi Casamtb,

Just a quick question, would this be the case al the time, or still be possible to work intermittently?

My JK does run fine a couple of km's into the journey, but soon limits itself.

A prime example is on a short desert drive this Friday. Had the described issue the first part of the ride, where after we stopped for a view for 20min (engine off) and the JK went fine again, though for only 5min or so.

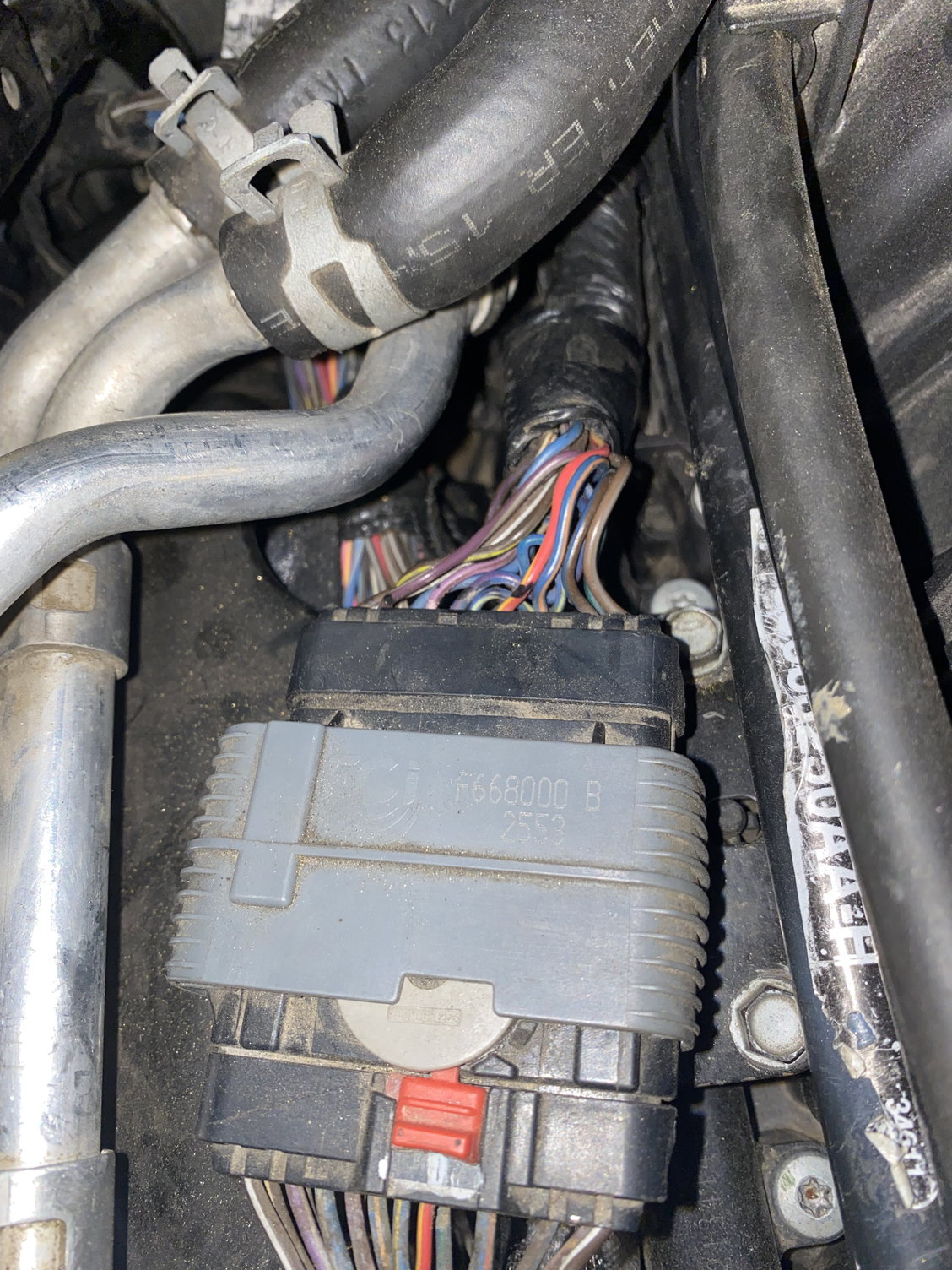

Really is getting to be more of an annoyance than a pleasure to take it out with mates, but always having to avoid the steep dunes as the engine cuts power. I have wrapped the solenoid wires with heat proof harness tape, all 4 on the front (2 under the throttle body, and 2 under the heater core hardline) before the trip, but still no luck.

Appreciate your time and inputs though, thanks

Just a quick question, would this be the case al the time, or still be possible to work intermittently?

My JK does run fine a couple of km's into the journey, but soon limits itself.

A prime example is on a short desert drive this Friday. Had the described issue the first part of the ride, where after we stopped for a view for 20min (engine off) and the JK went fine again, though for only 5min or so.

Really is getting to be more of an annoyance than a pleasure to take it out with mates, but always having to avoid the steep dunes as the engine cuts power. I have wrapped the solenoid wires with heat proof harness tape, all 4 on the front (2 under the throttle body, and 2 under the heater core hardline) before the trip, but still no luck.

Appreciate your time and inputs though, thanks

Last edited by Hiccup; 07-04-2021 at 02:43 AM.

The following users liked this post:

bujinkantd (01-10-2022)

The following users liked this post:

Hiccup (07-05-2021)

#17

I have yes

Use V-gate iCar Pro scanner along with a licensed JScan app. Have no codes at all no, and have had it coded at a couple of garages.

Used to have P0198 (oil temp sensor circuit high) and P0325 (knock sensor circuit), but all has been replaced and cleared more than a few months ago, along with a heap of other work.

Will have the guys replace the oil control valves, it can only help eliminate the possibilities, as it does feel a bit helpless at the moment.

Use V-gate iCar Pro scanner along with a licensed JScan app. Have no codes at all no, and have had it coded at a couple of garages.

Used to have P0198 (oil temp sensor circuit high) and P0325 (knock sensor circuit), but all has been replaced and cleared more than a few months ago, along with a heap of other work.

Will have the guys replace the oil control valves, it can only help eliminate the possibilities, as it does feel a bit helpless at the moment.

The following users liked this post:

bujinkantd (01-10-2022)

#18

I have yes

Use V-gate iCar Pro scanner along with a licensed JScan app. Have no codes at all no, and have had it coded at a couple of garages.

Used to have P0198 (oil temp sensor circuit high) and P0325 (knock sensor circuit), but all has been replaced and cleared more than a few months ago, along with a heap of other work.

Will have the guys replace the oil control valves, it can only help eliminate the possibilities, as it does feel a bit helpless at the moment.

Use V-gate iCar Pro scanner along with a licensed JScan app. Have no codes at all no, and have had it coded at a couple of garages.

Used to have P0198 (oil temp sensor circuit high) and P0325 (knock sensor circuit), but all has been replaced and cleared more than a few months ago, along with a heap of other work.

Will have the guys replace the oil control valves, it can only help eliminate the possibilities, as it does feel a bit helpless at the moment.

I have went on a business trip for a week So I wonít be able to do any further driving until

in back. I really want this to be resolved but I really donít think this fixed the problem but thatís how this issue is for me. It will happen completely random.

Starting

Middle

Done

The following 3 users liked this post by djdowney:

#19

It's a good sign at least.

I have not wrapped that specific plug myself, only the solenoid wires. Might as well wrap the whole harness. Hope it lasts for you, as it might be a real simple solution to a very annoying problem.

I have not wrapped that specific plug myself, only the solenoid wires. Might as well wrap the whole harness. Hope it lasts for you, as it might be a real simple solution to a very annoying problem.

The following users liked this post:

bujinkantd (01-10-2022)

#20

Hi all, just a quick update after having had my Jeep at a friend's shop over the last couple of days.

I have in-between earlier to now wrapped the harness plug, solenoid wires and removed the hood liner, still no luck. Had a call with the mechanic today, and he is fairly certain it is a failed oil pump. (Credit to Casamtb as he initially pointed to a mechanical issue with the oil system as well.)

3.6 Penta has a dual stage/dual pressure oil pump, which needs to switch between high and low pressure flow at around 3200rpm to advance or retard the VVT as necessary. If it does not switch between the high/low, there is no immediate risk of running the engine dry, however it will not allow for timing adjustment as far as I understood. In my case, the second stage would turn off intermittently, hence the problem not always being present.

Awaiting on parts prices, and will keep you guys posted over the following week or so as we have a drive for mid next week. Would be appreciated if anyone has had experience with this before, or think this could/would resolve the problem.

Thanks

I have in-between earlier to now wrapped the harness plug, solenoid wires and removed the hood liner, still no luck. Had a call with the mechanic today, and he is fairly certain it is a failed oil pump. (Credit to Casamtb as he initially pointed to a mechanical issue with the oil system as well.)

3.6 Penta has a dual stage/dual pressure oil pump, which needs to switch between high and low pressure flow at around 3200rpm to advance or retard the VVT as necessary. If it does not switch between the high/low, there is no immediate risk of running the engine dry, however it will not allow for timing adjustment as far as I understood. In my case, the second stage would turn off intermittently, hence the problem not always being present.

Awaiting on parts prices, and will keep you guys posted over the following week or so as we have a drive for mid next week. Would be appreciated if anyone has had experience with this before, or think this could/would resolve the problem.

Thanks

The following 3 users liked this post by Hiccup: