transfer case exploded

#51

JK Enthusiast

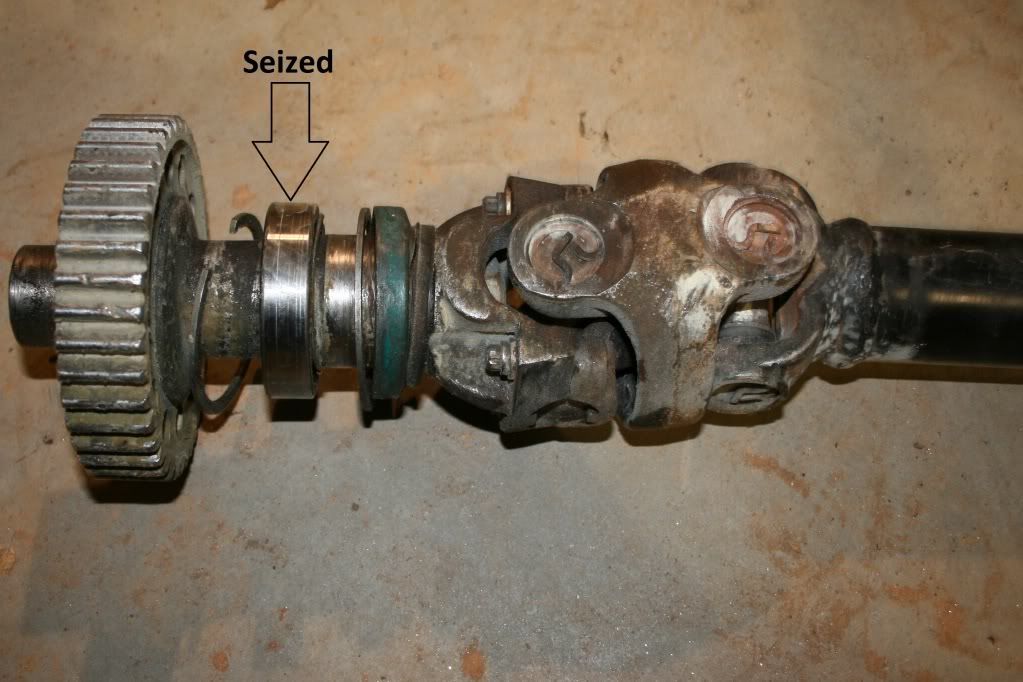

Got an update for transfer case breakage. center joint in front double cardan driveshaft that takes the needle fitting for grease never got serviced. When it failed, it locked up the joint and broke the front out of the transfer case. Expensive lesson learned, but not the equipments fault. My fault for lack of appropriate maintenance. Anyway, i'll be greasing those at 1,000 mile intervals from here on out. thanks for the input.

Last edited by dsp; 02-05-2011 at 02:39 PM.

#52

JK Enthusiast

if i'm reading this correctly, you say that you've had these shafts on since 2007? just out of curiosity, when was the last time you serviced your centering ball and checked your u-joints? depending on your location and how much water/salt they see, checking/changing out u-joints once every 2 years is something you should be doing. could be that the bearing in one or more of the joints were toast and finally ceased up.

#53

JK Jedi Master

Join Date: Jan 2008

Location: Austin <--> Colorado Springs

Posts: 11,463

Likes: 0

Received 162 Likes

on

154 Posts

Aftermaket Double Cardans - you pull the shaft off so you can actually get to the fitting, then use a needle.

#54

JK Enthusiast

Join Date: Nov 2010

Location: Luling,La.

Posts: 349

Likes: 0

Received 0 Likes

on

0 Posts

and they try to argue the man down, eddie you nailed it when you first responded, dont worry brother i trusted you from the jump. i would almost be willing to bet... you smiled a lil, i know i sure did

#55

JK Freak

Glad the OP figured out his problem and that maintenance goes a long way

I am not understanding something here.

WOL mentioned to use yokes. But why is this?

I have Rubicon Express driveshafts front and rear on a 4.5" lift. the frnt has a replacement yoke and the rear has a replacement flange adapter. are you suppose to be able to run a yoke on the rear also? well either way, I have now run these shafts with zero issues on and offroad for nearly 3 years over 60,000 miles. for whatever reason I never hear anything about RE driveshafts. they are 1310 and 1311 with Spicer parts

I am not understanding something here.

WOL mentioned to use yokes. But why is this?

I have Rubicon Express driveshafts front and rear on a 4.5" lift. the frnt has a replacement yoke and the rear has a replacement flange adapter. are you suppose to be able to run a yoke on the rear also? well either way, I have now run these shafts with zero issues on and offroad for nearly 3 years over 60,000 miles. for whatever reason I never hear anything about RE driveshafts. they are 1310 and 1311 with Spicer parts

#57

JK Super Freak

Join Date: Jul 2008

Location: Middle of no where

Posts: 1,934

Likes: 0

Received 0 Likes

on

0 Posts

Im not arguing the man down, I am having a discussion. Maybe you should get a mind of your own.

#58

JK Super Freak

Join Date: Jul 2008

Location: Middle of no where

Posts: 1,934

Likes: 0

Received 0 Likes

on

0 Posts

Got an update for transfer case breakage. center joint in front double cardan driveshaft that takes the needle fitting for grease never got serviced. When it failed, it locked up the joint and broke the front out of the transfer case. Expensive lesson learned, but not the equipments fault. My fault for lack of appropriate maintenance. Anyway, i'll be greasing those at 1,000 mile intervals from here on out. thanks for the input.

Last edited by Ryanc; 02-06-2011 at 06:04 AM.

#59

I would have to physically inspect the parts before I would comment on this exact failure. I'm just saying the transfer case failure is plausible. If any part of the rotating mass locked up it would find the weakest link really quick.

Edit: It does not take much for two pieces of hardened steel to gauld and seize together. The lack of lubrication to a point like this will cause extreme binding.

Last edited by toymaster; 02-06-2011 at 05:56 AM.

#60

JK Enthusiast

Join Date: Aug 2010

Location: Duncan, Ok

Posts: 233

Likes: 0

Received 0 Likes

on

0 Posts

Actually, I can understand exactly how a bad u-joint on a double card design could induce high frequency vibrations. That aluminum transfer can easily break apart when high frequency vibrations are induced.