RpmExtreme Official GEN4 LS Swap Thread 2007-2011 JK

#21

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

Here is a picture of our optional cruise-TAP switch for the 2011+ LS conversions.

With this switch you can control your TAP shift right from the steering wheel. No need to hack up your dash to bolt in a toggle switch or grind out your shifter.

With this switch you can control your TAP shift right from the steering wheel. No need to hack up your dash to bolt in a toggle switch or grind out your shifter.

#22

JK Freak

Join Date: Aug 2008

Location: King George, VA

Posts: 722

Likes: 0

Received 0 Likes

on

0 Posts

Do you have the part number for this switch? Also, do I need to change the wiring harness in the steering wheel?

#23

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

If your running our kit you don't have to change the steering wheel harness, just bolt in the switch. You will have to call and order the switch directly from us.

This is for the 2011 and newer steering wheels with factory cruise.

#24

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

Ok I figured it was time for a few updates.

We have been doing a lot of R&D testing lately and have some really cool new features and engine-transmission calibrations in the works. Ill go over a few of them.

First it has been hot as heck here in Alabama so we took advantage if it. Our 500HP 6.2 is the perfect vehicle to test cooling systems so we strapped on a trailer and proceeded to blast it up and down the highway while monitoring several parameters. What we found led me on a quest for more cooling, both engine and transmission.

The first thing that jumped out was the transmission temps. They were running much higher than I like to see. We reworked our trans cooler setup and that helped a little bit but the real gains we done once I went in and tweaked the transmission calibration. For some reason GM programs the torque converter clutch to slip when its engaged. By tweaking the calibration and lowering the slip to 0 we were able to lower the heat that was generated in the torque converter. We didn't stop there. We also adjusted when and how much pressure is applied to lock and unlock the TCC. This allowed us to lock it up much smother and with a little more force to compensate for the weight and tire size of the big JK. By doing all these things we saw a 50º drop in trans temps and a 1-2 MPG increase in fuel economy.

We also have several Jeeps running our Pentastar Fan upgrade. We have full control of the Pentastar fan from either the GM side or the Jeep side. We chose to use the Jeep side to control the fan. By using the Jeep side your running the fan the way Chrysler intended it to run. The TIPM was designed to run this fan and it makes it very easy to add to earlier JKs. By using the Jeep side you can monitor fan speeds and even control them with a scan tool plugged into the Jeep OBD2 port. With our EzCANbus module we can run this fan at variable speed based on engine temp, AC pressures, trans temp and pretty much any other parameter we want to monitor. Whats nice is we vary how fast the fan is based on AC pressures so when AC pressure is lower we run the fan at a quiet lower speed, but if its real hot outside and the pressures are up we will run the fan up to a higher speed and keep the airflow thru the condenser high. This gives us a much more consistent AC outlet temp and by keeping the pressures down yields less drag on the engine because it doesn't have to turn the compressor as hard.

Using the slim Pentastar fan has opened up some extra room between the radiator and the water pump. This allowed us to develop a few new radiators. In addition to our current high flow aluminum radiator we will be releasing a HD aluminum radiator and an Extreme Duty aluminum radiator. All will still be a direct plug and play radiator that will accept the JK condenser and both types of fans. As we start pushing these JKs past 500HP cooling really becomes a concern in hot climates.

I have yet to test it but I'm confident that we could install the pentastar fan in any earlier JK and program it to work like factory. So guys with superchargers and big winches that want extra cooling or are just tired of the crappy stock fan failing every time you get mud in it give us a call. We may come out with a upgrade kit.

This goes for the HEMI guys also. As long as your Jeep ECU isn't locked we can help you out too because we know you need more cooling.

During our offroad testing we came up with a few new tweaks.

We now have 2nd gear start based on shifter position. There were times when I wanted a little more control offroad and by adding 2nd gear start I was able to power thru some areas without slipping the tires. This would also come in real handy in snow and sand, similar to how a lot of european vehicles have a winter mode.

Our EzCANbus module also allows us to send the 4WD low signal from the Jeep side to the GM side. If you have a LS powered Jeep you may notice it shifts funny or hits the speed limiter in 4wd low. Thats because with the gear reduction the GM side thinks it running 90mph when your going 20 and the shift patterns are based on throttle % and vehicle speed. We are able to send the correct signal to the GM side and when in 4wd low it will adjust the speed based on Tcase ratio and move over to a different shift speed calibration and throttle settings among other things. This allows us to setup a totally different shift schedule for offroad. we can tailer it for offroad use and maximum traction, the last thing you want is the dam thing to kick down and bust the tires loose when your climbing the side of a mountain.

For engines with larger camshafts affecting the engine vacuum at idle and causing the brakes to feel hard. We are able to control an aux Brake Vacuum pump. We can have it commanded on based on engine vacuum or only when the brakes are applied in 4wd. Granted with proper tuning a 500 HP engine usually has enough vacuum for the brakes but at times offroad and in 4 low you could use a little extra braking.

AC idle bump. up until now any one instilling a LS into a non newer GM vehicle with AC could not send the proper message to the GM ECU telling it that AC was requested. Not a huge deal but it did cause some issues. Originally the GM ECU would see an AC request from the heater controls, it would then look at some parameters bump up the idle, crank up the fan and then turn the compressor on. By bumping the idle before it turned on the fan or compressor the engine RPM stayed very steady and you wouldn't feel the AC kicking in and out. When someone did a LS swap in the past there was no good way to send the AC request signal to the GM ECU so when you turn the AC on the engine speed drops down the then the GM side will try to compensate for it. It also doesn't know that you requested AC and will never turn the fan on accordingly as well as high rpm and throttle cutouts. With our EzCANbus module we are able to handle the high and low pressure cutouts, high or low RPM cutouts, high throttle cutouts and fan settings. We also add in if the engine temp reaches a certain temp it will disable the AC. We can now send the AC request signal to the GM ECU and get the idle bump. A lot of stock engines may never feel the AC kick in and thats fine but if you do have one that dips we can help out.

We are also testing a high idle winch setting.

Basically it will be a setting where once engaged will raise the idle to a high set point currently 1150 RPMs. This will allow you to winch much more efficiently and keep the battery charge rate up.

Im still working on the specific sequence to engage the high idle mode. It will be something like in 4wd, in Park, turn on cruise and apply the parking brake.

If there are any other cool features you guys can think of send me a PM and maybe we can get them added at some point.

We have been doing a lot of R&D testing lately and have some really cool new features and engine-transmission calibrations in the works. Ill go over a few of them.

First it has been hot as heck here in Alabama so we took advantage if it. Our 500HP 6.2 is the perfect vehicle to test cooling systems so we strapped on a trailer and proceeded to blast it up and down the highway while monitoring several parameters. What we found led me on a quest for more cooling, both engine and transmission.

The first thing that jumped out was the transmission temps. They were running much higher than I like to see. We reworked our trans cooler setup and that helped a little bit but the real gains we done once I went in and tweaked the transmission calibration. For some reason GM programs the torque converter clutch to slip when its engaged. By tweaking the calibration and lowering the slip to 0 we were able to lower the heat that was generated in the torque converter. We didn't stop there. We also adjusted when and how much pressure is applied to lock and unlock the TCC. This allowed us to lock it up much smother and with a little more force to compensate for the weight and tire size of the big JK. By doing all these things we saw a 50º drop in trans temps and a 1-2 MPG increase in fuel economy.

We also have several Jeeps running our Pentastar Fan upgrade. We have full control of the Pentastar fan from either the GM side or the Jeep side. We chose to use the Jeep side to control the fan. By using the Jeep side your running the fan the way Chrysler intended it to run. The TIPM was designed to run this fan and it makes it very easy to add to earlier JKs. By using the Jeep side you can monitor fan speeds and even control them with a scan tool plugged into the Jeep OBD2 port. With our EzCANbus module we can run this fan at variable speed based on engine temp, AC pressures, trans temp and pretty much any other parameter we want to monitor. Whats nice is we vary how fast the fan is based on AC pressures so when AC pressure is lower we run the fan at a quiet lower speed, but if its real hot outside and the pressures are up we will run the fan up to a higher speed and keep the airflow thru the condenser high. This gives us a much more consistent AC outlet temp and by keeping the pressures down yields less drag on the engine because it doesn't have to turn the compressor as hard.

Using the slim Pentastar fan has opened up some extra room between the radiator and the water pump. This allowed us to develop a few new radiators. In addition to our current high flow aluminum radiator we will be releasing a HD aluminum radiator and an Extreme Duty aluminum radiator. All will still be a direct plug and play radiator that will accept the JK condenser and both types of fans. As we start pushing these JKs past 500HP cooling really becomes a concern in hot climates.

I have yet to test it but I'm confident that we could install the pentastar fan in any earlier JK and program it to work like factory. So guys with superchargers and big winches that want extra cooling or are just tired of the crappy stock fan failing every time you get mud in it give us a call. We may come out with a upgrade kit.

This goes for the HEMI guys also. As long as your Jeep ECU isn't locked we can help you out too because we know you need more cooling.

During our offroad testing we came up with a few new tweaks.

We now have 2nd gear start based on shifter position. There were times when I wanted a little more control offroad and by adding 2nd gear start I was able to power thru some areas without slipping the tires. This would also come in real handy in snow and sand, similar to how a lot of european vehicles have a winter mode.

Our EzCANbus module also allows us to send the 4WD low signal from the Jeep side to the GM side. If you have a LS powered Jeep you may notice it shifts funny or hits the speed limiter in 4wd low. Thats because with the gear reduction the GM side thinks it running 90mph when your going 20 and the shift patterns are based on throttle % and vehicle speed. We are able to send the correct signal to the GM side and when in 4wd low it will adjust the speed based on Tcase ratio and move over to a different shift speed calibration and throttle settings among other things. This allows us to setup a totally different shift schedule for offroad. we can tailer it for offroad use and maximum traction, the last thing you want is the dam thing to kick down and bust the tires loose when your climbing the side of a mountain.

For engines with larger camshafts affecting the engine vacuum at idle and causing the brakes to feel hard. We are able to control an aux Brake Vacuum pump. We can have it commanded on based on engine vacuum or only when the brakes are applied in 4wd. Granted with proper tuning a 500 HP engine usually has enough vacuum for the brakes but at times offroad and in 4 low you could use a little extra braking.

AC idle bump. up until now any one instilling a LS into a non newer GM vehicle with AC could not send the proper message to the GM ECU telling it that AC was requested. Not a huge deal but it did cause some issues. Originally the GM ECU would see an AC request from the heater controls, it would then look at some parameters bump up the idle, crank up the fan and then turn the compressor on. By bumping the idle before it turned on the fan or compressor the engine RPM stayed very steady and you wouldn't feel the AC kicking in and out. When someone did a LS swap in the past there was no good way to send the AC request signal to the GM ECU so when you turn the AC on the engine speed drops down the then the GM side will try to compensate for it. It also doesn't know that you requested AC and will never turn the fan on accordingly as well as high rpm and throttle cutouts. With our EzCANbus module we are able to handle the high and low pressure cutouts, high or low RPM cutouts, high throttle cutouts and fan settings. We also add in if the engine temp reaches a certain temp it will disable the AC. We can now send the AC request signal to the GM ECU and get the idle bump. A lot of stock engines may never feel the AC kick in and thats fine but if you do have one that dips we can help out.

We are also testing a high idle winch setting.

Basically it will be a setting where once engaged will raise the idle to a high set point currently 1150 RPMs. This will allow you to winch much more efficiently and keep the battery charge rate up.

Im still working on the specific sequence to engage the high idle mode. It will be something like in 4wd, in Park, turn on cruise and apply the parking brake.

If there are any other cool features you guys can think of send me a PM and maybe we can get them added at some point.

Last edited by rpmextreme; 08-14-2016 at 05:56 AM.

#25

JK Enthusiast

So, your saying that us with the earlier installs can do the ezcanbus switch over and then have access to all these benefits?  I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

#26

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

So, your saying that us with the earlier installs can do the ezcanbus switch over and then have access to all these benefits?  I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

I am seeing a lot of what you are talking about in my setup now. If and when I get my current state taking care of looks like some up grades are in order!

Yes most of the benefits could be implemented. There are a few upgrade paths to add a EZcanbus to our older GEN4 kits. If your looking for just the pentastar fan, I think we can add it to yours the way it sits and make it work. I will be testing that on our GEN3 shop Jeep.

I should be able to add a pentastar fan to a stock 07-11 JK using all stock computers, no canbus stuff needed there.

AC idle bump and winch mode are both in the testing phase and showing promise. I won't add them to the kit until they are fully tested. Once approved a simple reflash of the EZcanbus will add these features for customers currently running our canbus equipped kits.

#27

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

Here are my thoughts on gearing and tire size. The 6L80E has much better gearing compared to the stock JK trans. 1st gear is much lower and it has 2 overdrives. Offroad you will be fine with the stock 241J transfer case and whatever gear you choose. The super low 1st gear will give you all you need in 4 low. Highway driving is what you need to be thinking about.

My personal Jeep 2011 JKU 6.2 around 500HP and 6L80E. Bumpers, winch all the usual stuff. 37" MTRs and 4.56 gears.

With 4.56 gears and 37's it does great on the highway and runs around 1900 rpm @ 70MPH it will hold 6th gear and chug over most hills without even downshifting. Granted I have more power than most but I have ran 5.3s and stock 6.2s in this jeep with the same gearing and tire size and it always did well.

We just finished up a 10JKU 6.2 430HP 37's 4.56 gears. It did very well and would run 80 MPH all day long without breaking a sweat or dropping out of 6th gear.

A 5.3 in a big heavy JK may struggle a little bit holding 6th gear as it doesn't have as much torque as the 6.2 but with proper transmission programing it will drop to 5th, pick up about 400 rpm's and pull over most hills without straining.

We usually like to run the 5.3's with a little more gear if you don't have access to a good transmission tuner.

Transmission tuning is key here guys. The calibration that is in the trans computer is set up for the factory vehicle it was pulled from. Everything they do is geared towards a stock vehicle with light tires and crappy gearing. All they care about is smooth shifts, fuel economy and preserving the transmission from warranty claims. If you just drop in the trans without tuning it will drive and shift no problem. But it won't be anywhere near calibrated for the big heavy Jeep, tires size or gear ratio that your running. They will usually shift up too fast, downshift way to aggressively and be general mushy. We have spent a lot of time and effort making real world calibrations for these swaps and the improvements are truly night and day.

Fuel mileage was our first goal and by calibrating the transmission we were able to see pretty significant gains.

Second was highway manners. You have plenty of power now so lets use it. The stock calibration would kick out of 6th way to easy. we rework the shift schedule and allow you to use the torque of the engine to float over hills and maintain speeds without it kicking down and pulling high rpm's. Again this gained us fuel mileage and made it a pleasure to drive.

Third we worked on shift feel. We reworked the shift times and pressure onsets. This allows us to "tune" the trans feel to the weight of the vehicle. We can make if have a firm shift or an all out bark the tires "shift kit" feel. Personal preference here guys, you want bark the tires and snap necks? it can be done. We can even base the shift pressure on throttle position so you can have a nice smooth shift at light throttle and a hard aggressive shift at wide open throttle.

Forth we work on the shift schedule and shift points. This allows us to calibrate when and where it will shift. We allow it to build a little more speed before it shifts and make the lower speed downshifts a little more aggressive. While this may hurt fuel economy a bit it makes the Jeep feel like it has more power and is much more fun to drive.

Fifth we work on the TOW Haul mode. When in tow haul mode you have a separate shift schedule and we can tailer it to whatever you want. If you pull a camper or boat, we will set it up for max towing. If you want to play race car driver on the backroads we can do that too. Personally I have mine set to race car. It will REV match downshift coming into the corners like a Corvette and sounds freaking awesome.

Sixth we set up the 4WD Low shift pattern. This allows us to make a dedicated offroad shift schedule. This is useful when offroad and would be tailored to how you wheel. We even can add in a 2nd gear start for slick conditions like mud, sand and snow.

I crunched the numbers to show you guys what tire size and gear ratio would be with a 6L80E. These are all a 70MPH and probably within 25rpms depending on how good my math is.

6L08E....4.56...................4.88.............. ..........5.13..................RPM @ 70MPH

.......6th.........5th........6th........5th...... .....6th.........5th

35"..2050......2600......2200.....2800........2300 .......2950

37"..1950......2450......2100.....2650........2200 .......2800

40"..1800......2300......1925.....2450........2000 .......2600

Remember the faster you spin the engine the more heat it makes and fuel mileage will go down. If you spin it too slow you will be under the power curve and constantly having to downshift which will suck to drive and will suck fuel also.

I feel that the sweet spot for 5.3's is between 1900 and 2200 rpm's

The sweet spot for 6.2's is 1700 and 2000 rpm's

The sweet spot for 6.0's is 1600 and 1900 rpm's

Of coarse all of this will depend on your Jeep and driving style. I light 2 door that drives primary on the highway won't need to spin the engine near as fast as a big heavy 4 door.

If you don't spend a lot of time on the highway you can get away with running more gear.

My personal Jeep 2011 JKU 6.2 around 500HP and 6L80E. Bumpers, winch all the usual stuff. 37" MTRs and 4.56 gears.

With 4.56 gears and 37's it does great on the highway and runs around 1900 rpm @ 70MPH it will hold 6th gear and chug over most hills without even downshifting. Granted I have more power than most but I have ran 5.3s and stock 6.2s in this jeep with the same gearing and tire size and it always did well.

We just finished up a 10JKU 6.2 430HP 37's 4.56 gears. It did very well and would run 80 MPH all day long without breaking a sweat or dropping out of 6th gear.

A 5.3 in a big heavy JK may struggle a little bit holding 6th gear as it doesn't have as much torque as the 6.2 but with proper transmission programing it will drop to 5th, pick up about 400 rpm's and pull over most hills without straining.

We usually like to run the 5.3's with a little more gear if you don't have access to a good transmission tuner.

Transmission tuning is key here guys. The calibration that is in the trans computer is set up for the factory vehicle it was pulled from. Everything they do is geared towards a stock vehicle with light tires and crappy gearing. All they care about is smooth shifts, fuel economy and preserving the transmission from warranty claims. If you just drop in the trans without tuning it will drive and shift no problem. But it won't be anywhere near calibrated for the big heavy Jeep, tires size or gear ratio that your running. They will usually shift up too fast, downshift way to aggressively and be general mushy. We have spent a lot of time and effort making real world calibrations for these swaps and the improvements are truly night and day.

Fuel mileage was our first goal and by calibrating the transmission we were able to see pretty significant gains.

Second was highway manners. You have plenty of power now so lets use it. The stock calibration would kick out of 6th way to easy. we rework the shift schedule and allow you to use the torque of the engine to float over hills and maintain speeds without it kicking down and pulling high rpm's. Again this gained us fuel mileage and made it a pleasure to drive.

Third we worked on shift feel. We reworked the shift times and pressure onsets. This allows us to "tune" the trans feel to the weight of the vehicle. We can make if have a firm shift or an all out bark the tires "shift kit" feel. Personal preference here guys, you want bark the tires and snap necks? it can be done. We can even base the shift pressure on throttle position so you can have a nice smooth shift at light throttle and a hard aggressive shift at wide open throttle.

Forth we work on the shift schedule and shift points. This allows us to calibrate when and where it will shift. We allow it to build a little more speed before it shifts and make the lower speed downshifts a little more aggressive. While this may hurt fuel economy a bit it makes the Jeep feel like it has more power and is much more fun to drive.

Fifth we work on the TOW Haul mode. When in tow haul mode you have a separate shift schedule and we can tailer it to whatever you want. If you pull a camper or boat, we will set it up for max towing. If you want to play race car driver on the backroads we can do that too. Personally I have mine set to race car. It will REV match downshift coming into the corners like a Corvette and sounds freaking awesome.

Sixth we set up the 4WD Low shift pattern. This allows us to make a dedicated offroad shift schedule. This is useful when offroad and would be tailored to how you wheel. We even can add in a 2nd gear start for slick conditions like mud, sand and snow.

I crunched the numbers to show you guys what tire size and gear ratio would be with a 6L80E. These are all a 70MPH and probably within 25rpms depending on how good my math is.

6L08E....4.56...................4.88.............. ..........5.13..................RPM @ 70MPH

.......6th.........5th........6th........5th...... .....6th.........5th

35"..2050......2600......2200.....2800........2300 .......2950

37"..1950......2450......2100.....2650........2200 .......2800

40"..1800......2300......1925.....2450........2000 .......2600

Remember the faster you spin the engine the more heat it makes and fuel mileage will go down. If you spin it too slow you will be under the power curve and constantly having to downshift which will suck to drive and will suck fuel also.

I feel that the sweet spot for 5.3's is between 1900 and 2200 rpm's

The sweet spot for 6.2's is 1700 and 2000 rpm's

The sweet spot for 6.0's is 1600 and 1900 rpm's

Of coarse all of this will depend on your Jeep and driving style. I light 2 door that drives primary on the highway won't need to spin the engine near as fast as a big heavy 4 door.

If you don't spend a lot of time on the highway you can get away with running more gear.

#28

Former Vendor

Thread Starter

Join Date: Mar 2012

Location: Alabama

Posts: 100

Likes: 0

Received 0 Likes

on

0 Posts

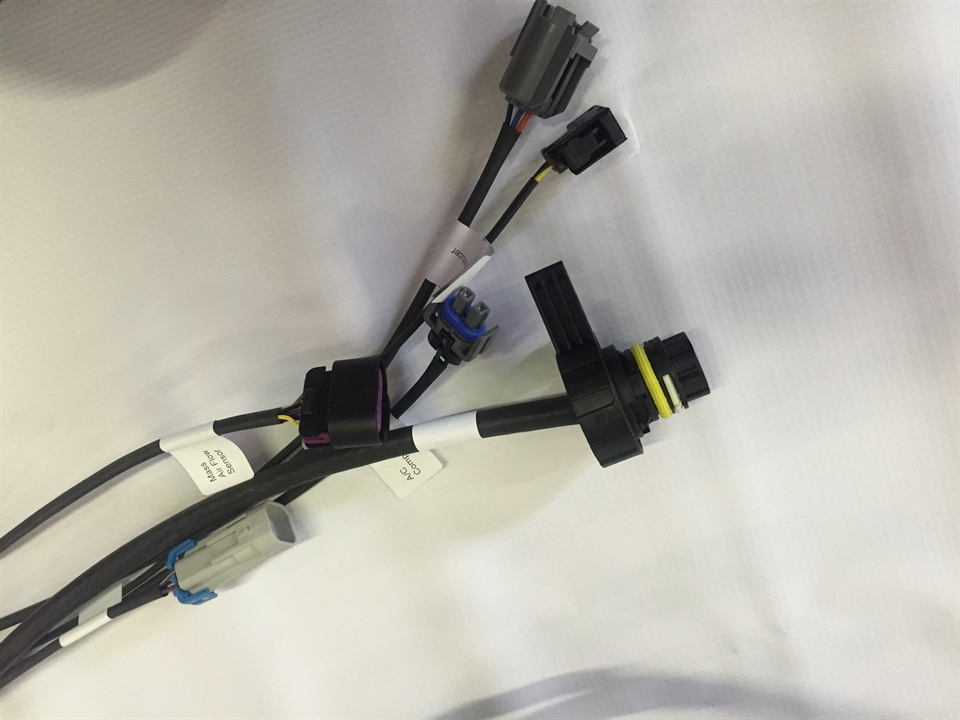

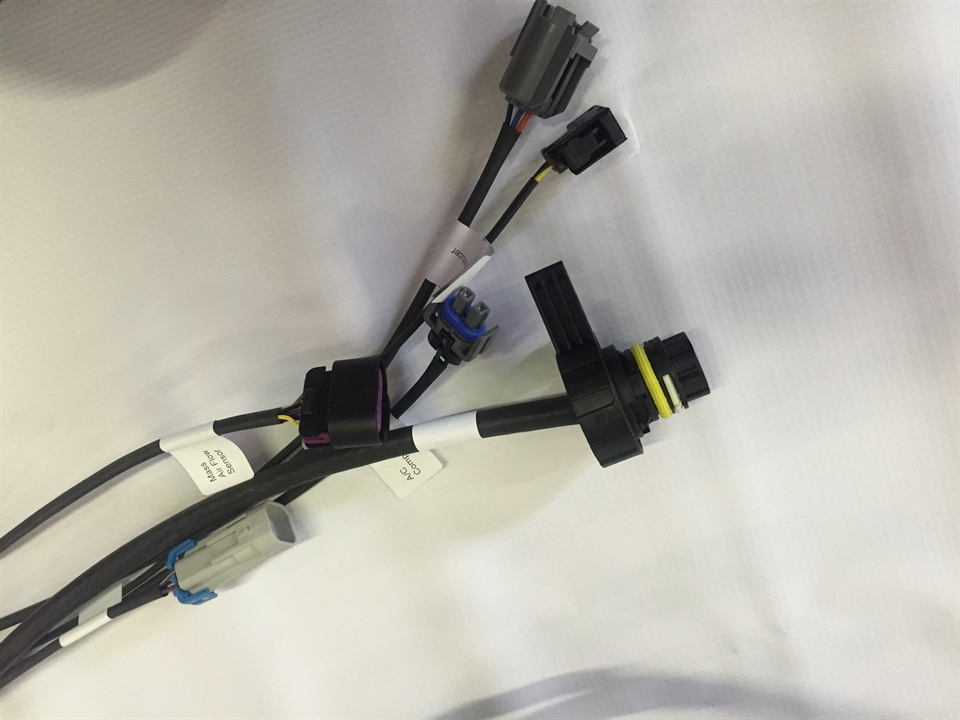

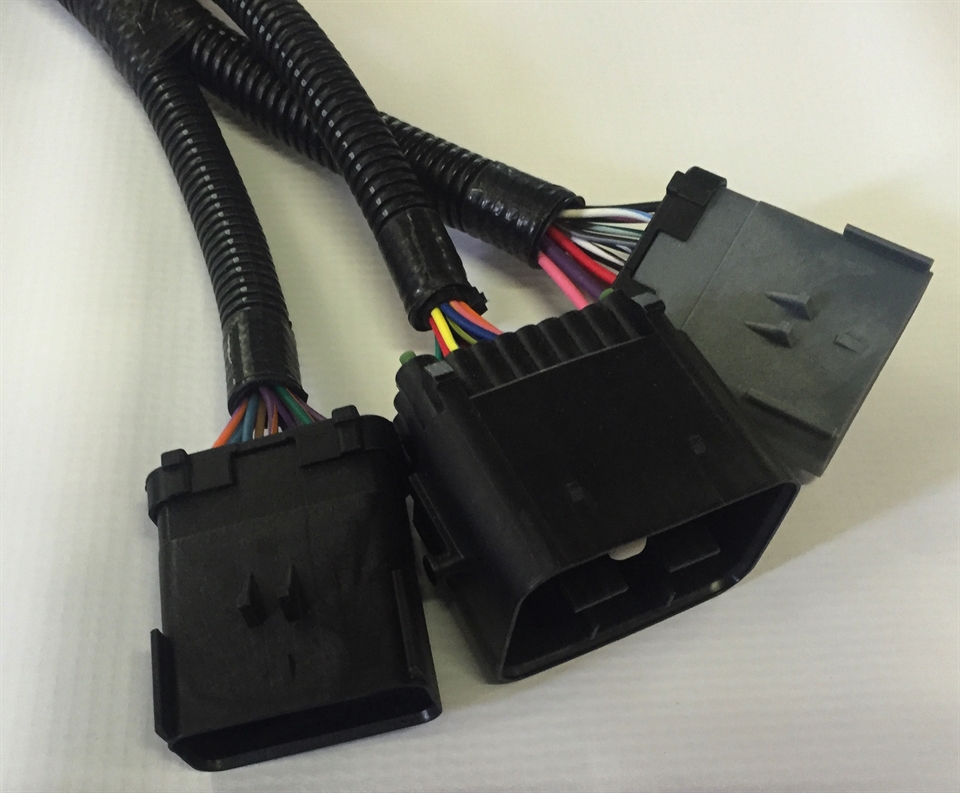

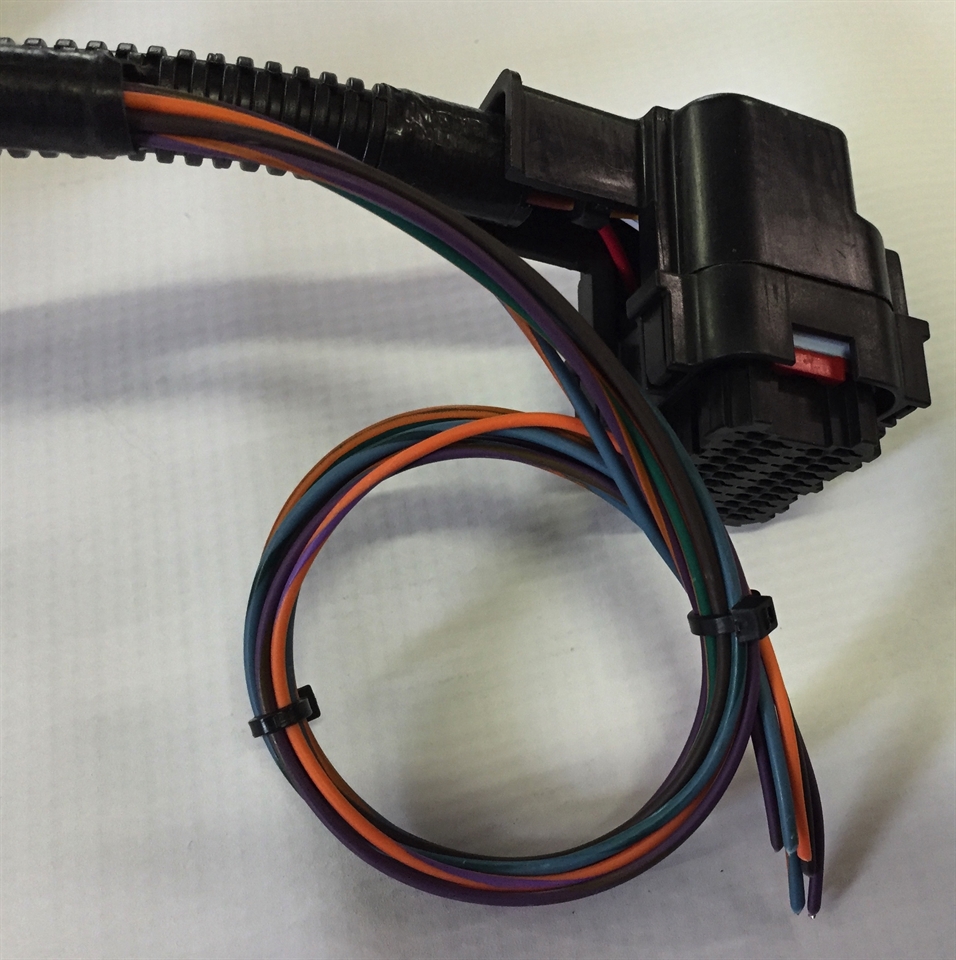

Here are some pictures to show how clean and simple the harness is.

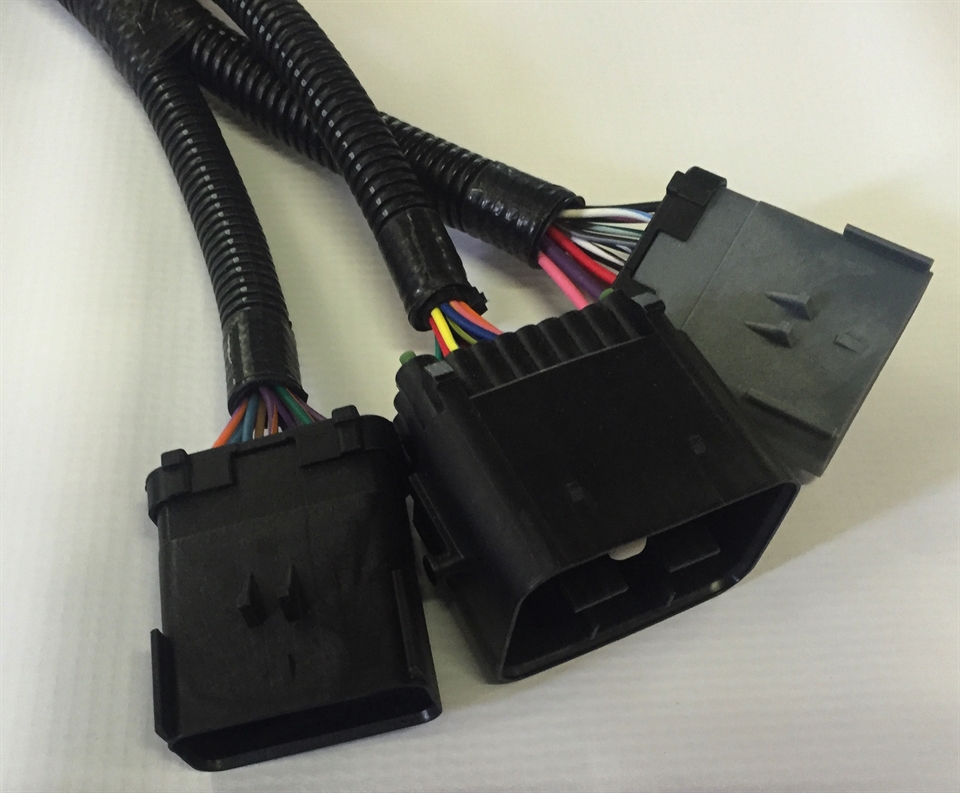

This is the brains behind the entire swap and we did all the hard stuff for you. All you have to do is plug it in and splice in 6 wires at the Jeep computer. Your not modifying inside the Jeep or splicing anything under the dash. It consist of two main harnesses, one under dash harness and one under hood harness.

The Under dash harness has the provisions for the ODB2 port, Accelerator pedal, Fuses & Relays and EZcanbus module fully assembled and ready to drop in. It also has two 14 way connectors that will go thru the firewall pass thru and plug directly into the under hood harness as well as a fusible link power feed that you will attach to the battery. Thats it....under dash work is done :grin2:

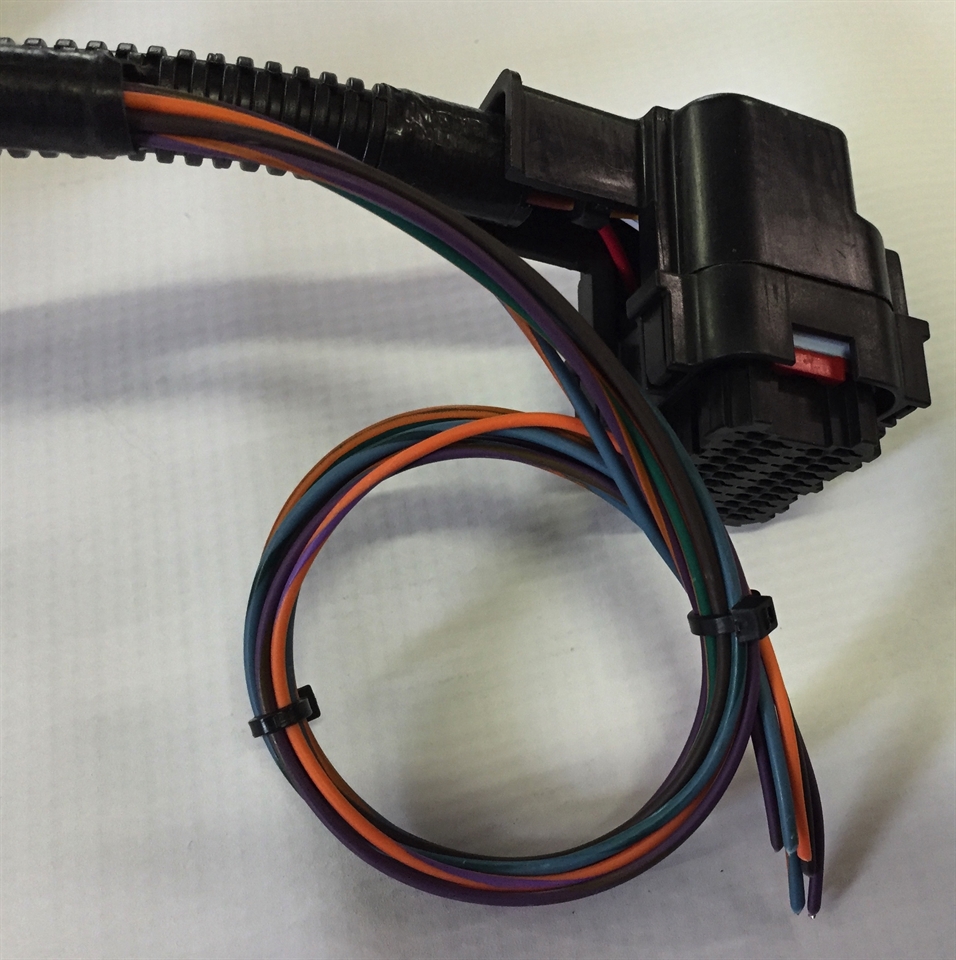

The second part is the under hood harness. It has the provisions for all the GM powertrain, routes behind the engine for a nice tidy clean install. Everything is labeled and plug and play.

The under hood harness with plug into the factory C100 connector at the firewall and into the under dash 14 way connectors. No guess work here, they only go one way.

The under hood harness has the Jeep computer C1 connector. You will not have a C2 or C4 plug anymore as its not needed. Branching off of the C1 plug is the 6 wires that we splice into the C3 connector. The reason we have to splice into the C3 is its part of the body harness and stays in the Jeep. We are basically splicing in to get our signals from the body side. All wires are color coded to match the factory colors. This is the only "wiring" you have to do as the rest is all plug and play.

Running along with the Jeep computer connector is the GM ECU connectors. The GM ECU will mount to the back of the Jeep computer and plugs right into our harness with the factory style cam lock connectors. We mount the GM ecu behind the Jeep ecu so its out of the way and looks professional. You can still use a sPOD :wink2:

Last but not least is all the factory style connectors. Everything from the 6L80E connector to the AC compressor is a factory style connector and they are fully labeled.

This is the brains behind the entire swap and we did all the hard stuff for you. All you have to do is plug it in and splice in 6 wires at the Jeep computer. Your not modifying inside the Jeep or splicing anything under the dash. It consist of two main harnesses, one under dash harness and one under hood harness.

The Under dash harness has the provisions for the ODB2 port, Accelerator pedal, Fuses & Relays and EZcanbus module fully assembled and ready to drop in. It also has two 14 way connectors that will go thru the firewall pass thru and plug directly into the under hood harness as well as a fusible link power feed that you will attach to the battery. Thats it....under dash work is done :grin2:

The second part is the under hood harness. It has the provisions for all the GM powertrain, routes behind the engine for a nice tidy clean install. Everything is labeled and plug and play.

The under hood harness with plug into the factory C100 connector at the firewall and into the under dash 14 way connectors. No guess work here, they only go one way.

The under hood harness has the Jeep computer C1 connector. You will not have a C2 or C4 plug anymore as its not needed. Branching off of the C1 plug is the 6 wires that we splice into the C3 connector. The reason we have to splice into the C3 is its part of the body harness and stays in the Jeep. We are basically splicing in to get our signals from the body side. All wires are color coded to match the factory colors. This is the only "wiring" you have to do as the rest is all plug and play.

Running along with the Jeep computer connector is the GM ECU connectors. The GM ECU will mount to the back of the Jeep computer and plugs right into our harness with the factory style cam lock connectors. We mount the GM ecu behind the Jeep ecu so its out of the way and looks professional. You can still use a sPOD :wink2:

Last but not least is all the factory style connectors. Everything from the 6L80E connector to the AC compressor is a factory style connector and they are fully labeled.