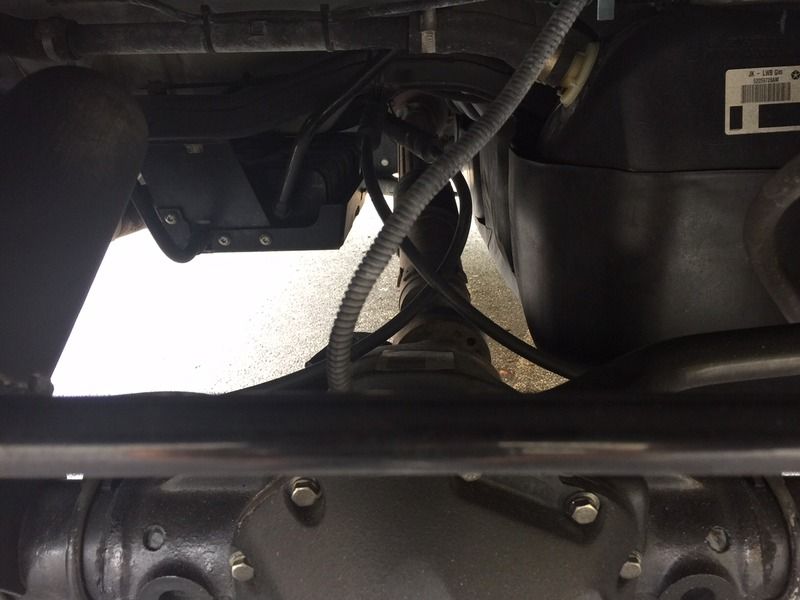

Rear OEM Driveshaft yoke hitting tank skid.

#21

Yes, it is offset to the passenger side, you can see in the picture.

Attachment 647866

Attachment 647866

And just to show what I'm talking about, here's my rear axle. I went to great lengths to level my trackbar! I have a 4" measured lift and about 6.5" or so raised trackbar using the aev trackbar tower which was the highest mount I could find. It uses a specially bent trackbar to clear the exhaust. My trackbar is probably within 1.5" of level (looking at the mounts not the bar.). And my axle shifts like a mofo! I had to significantly clearance my tank to keep the stock shaft! It's not like I don't have a level trackbar I'm telling you I already been through this, lol! If I lowered my trackbar in my bracket it hit the tank less but I wanted the highest roll center (best road handling) possible for a lifted DD wheeler. So I clearanced the tank.

Last edited by Biginboca; 05-24-2016 at 09:59 AM.

#22

By chance... do you have any close up pictures of what you did to clearance the tank?

My thoughts are to BFH the skid plate bolt into the plastic tank, or to pull the skid and plasma off that tab and hope that the skid still wants to live there up tight to the tank.

I don't have $$ right now for the track bar, before I spend on that, I really need a U-Joint style front driveshaft. I'm running the stock front with the boot burnt off. So far it's not complaining.... and I know that driveshafts for decades didn't have a boot... but that factory joint isn't going to live long with a 3.5 lift and hanging the axle by the shaft on the exhaust! At some point, something is going give.

I need to start prostituting myself out on street corners!

My thoughts are to BFH the skid plate bolt into the plastic tank, or to pull the skid and plasma off that tab and hope that the skid still wants to live there up tight to the tank.

I don't have $$ right now for the track bar, before I spend on that, I really need a U-Joint style front driveshaft. I'm running the stock front with the boot burnt off. So far it's not complaining.... and I know that driveshafts for decades didn't have a boot... but that factory joint isn't going to live long with a 3.5 lift and hanging the axle by the shaft on the exhaust! At some point, something is going give.

I need to start prostituting myself out on street corners!

#23

Thanks, I was just going to post this...

And just to show what I'm talking about, here's my rear axle. I went to great lengths to level my trackbar! I have a 4" measured lift and about 6.5" or so raised trackbar using the aev trackbar tower which was the highest mount I could find. It uses a specially bent trackbar to clear the exhaust. My trackbar is probably within 1.5" of level (looking at the mounts not the bar.). And my axle shifts like a mofo! I had to significantly clearance my tank to keep the stock shaft! It's not like I don't have a level trackbar I'm telling you I already been through this, lol! If I lowered my trackbar in my bracket it hit the tank less but I wanted the highest roll center (best road handling) possible for a lifted DD wheeler. So I clearanced the tank.

Last edited by Maertz; 05-24-2016 at 11:30 AM.

#24

Are those pics of a rubi or non rubi axle? I dont have any jk d44s to look at unless i drive to a dealership. I havent dealt with d44s in a long while and recall them having different ring gear locations and shaft lengths due to machining to fit the locker. I doubt they differ much at all im just curious now. Id say he should just get an aftermarket driveshaft and make sure axle is centered. I can see what your saying to a degree but its never been a topic of concern. I ran a flat (not bent) trackbar on mine before i went full custom double tri. And had zero problems at all. I understand geometry and such i was just wanting more info on your statement as i have never heard or seen this be a concern or topic of question. You still have a non adjustable track bar. Have you measured the centering of your axle by chance? Your saying you dropped the track bar down (maybe 1/2 between holes) and your axle shifted right (it does) but yet your driveshaft moved further from your gas tank (left)? Thought there may have been more of a valuable point you were trying to get to....if you wanted a good dd wheeler why did you lift 4" then? Are you running 40s for that much lift? 40s arent a good dd either so id guess no?

My rear axle is centered within 1/8".

I have synergy 3" springs which netted me an actual measured 3.5" lift. Then I added the coil correction wedges and it pushed me to 4" actual lift. I'm on 37's and have 4" up travel and 8" down travel. The set up is working well and handling great for me I'm running 85mph every day on way to work no issues. Here's how it sits I think it's about perfect amount of lift for my 37's...

Here's how the rear flexes. This is the same position as where I used to have the rubbing before I did my tank mods. Not saying it's amazing flex or anything but it flexes decent and now everything clears I can get full articulation all around perfectly silent nothing rubs, no pops, no weird noises or any noises at all on my rig. Since you built yours, and I love your build btw, I know you can appreciate that.

Last edited by Biginboca; 05-24-2016 at 02:40 PM.

#25

You

I have the stock tank skid only. I took a 10lb sledge to it to reform the tank. Pull the axle end of the driveshaft and hang it up high with a bungee around the crossmember. Then you'll have plenty of room to have at it. It's a hell of a workout! Took me a couple tries cause mine was rubbing over a large area and new rubs kept appearing as I fixed old ones. You only seem to have a small issue to address so shouldn't be too hard, mine was pretty crazy l! As you can see I had to reshape the back bottom inside corner of my tank over like a 1ft area...

By chance... do you have any close up pictures of what you did to clearance the tank?

My thoughts are to BFH the skid plate bolt into the plastic tank, or to pull the skid and plasma off that tab and hope that the skid still wants to live there up tight to the tank.

I don't have $$ right now for the track bar, before I spend on that, I really need a U-Joint style front driveshaft. I'm running the stock front with the boot burnt off. So far it's not complaining.... and I know that driveshafts for decades didn't have a boot... but that factory joint isn't going to live long with a 3.5 lift and hanging the axle by the shaft on the exhaust! At some point, something is going give.

I need to start prostituting myself out on street corners!

My thoughts are to BFH the skid plate bolt into the plastic tank, or to pull the skid and plasma off that tab and hope that the skid still wants to live there up tight to the tank.

I don't have $$ right now for the track bar, before I spend on that, I really need a U-Joint style front driveshaft. I'm running the stock front with the boot burnt off. So far it's not complaining.... and I know that driveshafts for decades didn't have a boot... but that factory joint isn't going to live long with a 3.5 lift and hanging the axle by the shaft on the exhaust! At some point, something is going give.

I need to start prostituting myself out on street corners!

#27

Yep I have the Exhaust Back Pressure upgrade on my Jeep too

I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub

I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub  . Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.

. Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.Here is a picture of the dent. Thats what I get for being flexible

Last edited by Jonathan_JK; 05-24-2016 at 04:43 PM.

#28

Yep I have the Exhaust Back Pressure upgrade on my Jeep too  I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub

I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub  . Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.

. Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.

Here is a picture of the dent. Thats what I get for being flexible

I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub

I'm just going to leave it haven't noticed any problems yet. Just say no to correct bump stops let the Tire go right into the tub  . Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.

. Being serious though I am going to upgrade to the correct hydro bump stops. I just hate to loose upward travel.Here is a picture of the dent. Thats what I get for being flexible

#29

lol... Well thats a relief. I though for sure my track bar had hit the exhaust when I blew my last set of rear shocks bottoming them out. So there is a guy at the Jeep assembly line who's job is to hit the exhaust with a hammer to dent the exhaust?

#30

I am sure the exhaust is dimpled in a hydraulic press before it ever gets on the jeep. I crawled under my first one when it was new and was like WTF lol.