Rear OEM Driveshaft yoke hitting tank skid.

#11

JK Super Freak

Yes, I changed nothing else. Noticed my ds was rubbing my tank on a wheeling trip, so decided to address it when I got home. Figured as the poster above did that if I raised the trackbar at the axle it would fix the issue. When I raised the trackbar and as mentioned the DS rubbed the tank even worse. Very annoying! So I started wondering why and researching what was wrong. What I found is what I posted above. The higher you raise the trackbar mount at the axle the larger the arc the pinion (and ds) swing through.

It's simple really when you look at the diagram I posted. Imagine a pendulum, the top is the center point of the trackbar mounts (moment center). The bottom of the pendulum is the pinion. For the same degrees of swing of the pendulum the longer the string (raising the moment center by moving the axle mount upwards) the more sideways travel of the bottom weight (pinion).

(Also don't forget the driveshaft doesn't enter the pumpkin in the center. The pinion is off center so driveshaft swings side to side as well as up and down when the axle articulates. This fact is what you are probably overlooking and now you will understand everything, I hope, lol!)

I don't think it's an issue for most cause they are using a boxed lift kit where the manufacturer has addressed these issues. Also stock driveshafts tend to get into the tank more than the aftermarket ones. If you are running a long travel (like 12" travel) shock and using all the travel with a stock rear driveshaft you will probably have the issue. At least that's what I experienced (with stock driveshaft, tank, and tank skid) and have observed on the forums.

During my research on what was happening I googled "jk driveshaft hitting fuel tank" and found a bunch of threads.

Last edited by Biginboca; 05-23-2016 at 04:58 PM.

#13

JK Enthusiast

In the picture, I see two fingers of normal clearance between the bolt and the DS. I am thinking there is too much side to side play in the track bar setup. I was looking at the Mopar trackbar bracket and it is a bolt on plate. I am not impressed with bolt on suspension components because they flex too much. I think this flex coupled with the rubber TB end bushings are giving you the extra side to side flex when the weight of the vehicle is pushing the axle sideways.

The best bushings are neoprene or steel Johnny Joints that have very little give.

I recommend:

1. Countersink the skid plate and install a flathead bolt.

2. Ensure the rear TB bracket is tight and not flexing. If it is, weld it on...

3. Get an adjustable TB with Johnny Joint ends to eliminate side to side motion. Adjust it until there is no rubbing and as close to centered as possible.

The best bushings are neoprene or steel Johnny Joints that have very little give.

I recommend:

1. Countersink the skid plate and install a flathead bolt.

2. Ensure the rear TB bracket is tight and not flexing. If it is, weld it on...

3. Get an adjustable TB with Johnny Joint ends to eliminate side to side motion. Adjust it until there is no rubbing and as close to centered as possible.

#14

JK Enthusiast

Yes the OP should push his axle a little more to the drivers side with a longer trackbar or modify (or remove if aftermarket) the fuel tank/tank skid, or get a smaller diameter pinion flange on a aftermarket driveshaft.

Yes, I changed nothing else. Noticed my ds was rubbing my tank on a wheeling trip, so decided to address it when I got home. Figured as the poster above did that if I raised the trackbar at the axle it would fix the issue. When I raised the trackbar and as mentioned the DS rubbed the tank even worse. Very annoying! So I started wondering why and researching what was wrong. What I found is what I posted above. The higher you raise the trackbar mount at the axle the larger the arc the pinion (and ds) swing through.

It's simple really when you look at the diagram I posted. Imagine a pendulum, the top is the center point of the trackbar mounts (moment center). The bottom of the pendulum is the pinion. For the same degrees of swing of the pendulum the longer the string (raising the moment center by moving the axle mount upwards) the more sideways travel of the bottom weight (pinion).

(Also don't forget the driveshaft doesn't enter the pumpkin in the center. The pinion is off center so driveshaft swings side to side as well as up and down when the axle articulates. This fact is what you are probably overlooking and now you will understand everything, I hope, lol!)

I don't think it's an issue for most cause they are using a boxed lift kit where the manufacturer has addressed these issues. Also stock driveshafts tend to get into the tank more than the aftermarket ones. If you are running a long travel (like 12" travel) shock and using all the travel with a stock rear driveshaft you will probably have the issue. At least that's what I experienced (with stock driveshaft, tank, and tank skid) and have observed on the forums.

During my research on what was happening I googled "jk driveshaft hitting fuel tank" and found a bunch of threads.

Yes, I changed nothing else. Noticed my ds was rubbing my tank on a wheeling trip, so decided to address it when I got home. Figured as the poster above did that if I raised the trackbar at the axle it would fix the issue. When I raised the trackbar and as mentioned the DS rubbed the tank even worse. Very annoying! So I started wondering why and researching what was wrong. What I found is what I posted above. The higher you raise the trackbar mount at the axle the larger the arc the pinion (and ds) swing through.

It's simple really when you look at the diagram I posted. Imagine a pendulum, the top is the center point of the trackbar mounts (moment center). The bottom of the pendulum is the pinion. For the same degrees of swing of the pendulum the longer the string (raising the moment center by moving the axle mount upwards) the more sideways travel of the bottom weight (pinion).

(Also don't forget the driveshaft doesn't enter the pumpkin in the center. The pinion is off center so driveshaft swings side to side as well as up and down when the axle articulates. This fact is what you are probably overlooking and now you will understand everything, I hope, lol!)

I don't think it's an issue for most cause they are using a boxed lift kit where the manufacturer has addressed these issues. Also stock driveshafts tend to get into the tank more than the aftermarket ones. If you are running a long travel (like 12" travel) shock and using all the travel with a stock rear driveshaft you will probably have the issue. At least that's what I experienced (with stock driveshaft, tank, and tank skid) and have observed on the forums.

During my research on what was happening I googled "jk driveshaft hitting fuel tank" and found a bunch of threads.

I have read this several times and don't understand what you are saying. I think this is because you are using the Moment Center concept that really shouldn't be applied here. With respect to the motion of the axle (in this situation), there are 2 pivot points. One at the TB where it connects to the body and the other where it connects to the axle. The axle doesn't pivot around it's center. Neither does the TB. If the right wheel goes down in a hole, the axle will pivot at the point where the TB connects to the Axle. If the left wheel goes in a hole, the axle will pivot where the TB connects to the body.

#15

JK Super Freak

I have read this several times and don't understand what you are saying. I think this is because you are using the Moment Center concept that really shouldn't be applied here. With respect to the motion of the axle (in this situation), there are 2 pivot points. One at the TB where it connects to the body and the other where it connects to the axle. The axle doesn't pivot around it's center. Neither does the TB. If the right wheel goes down in a hole, the axle will pivot at the point where the TB connects to the Axle. If the left wheel goes in a hole, the axle will pivot where the TB connects to the body.

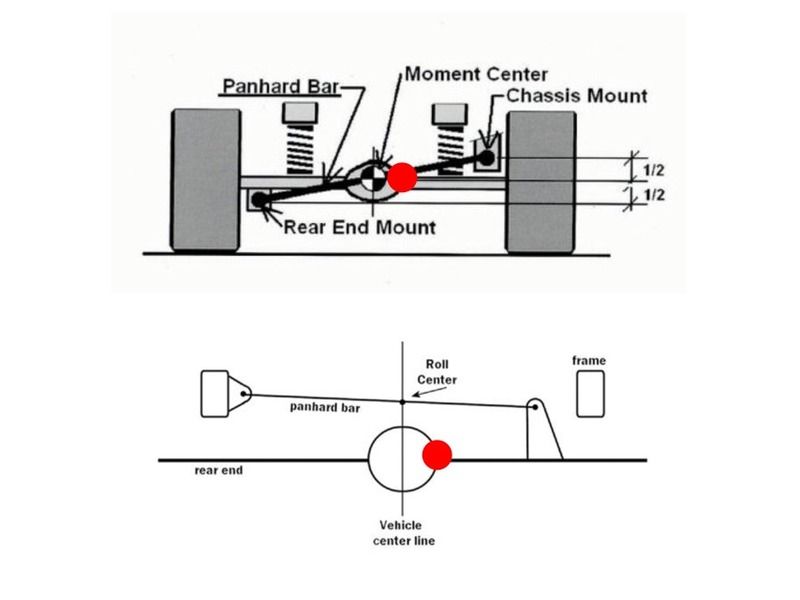

The pivot point of the axle isn't it's center either. It' pivots at the moment center which is always the halfway point between the trackbar mounts, just like in the diagram.

The crazy thing is the moment center is always changing as the suepsnion compresses and droops, but it's always that same halfway point!

The diagram below is my last try at explaining this. We don't need to argue we just need to enjoy our jeeps, lol

The top is a stock jeep. (Moment center = Roll Center)

The bottom is a lifted jeep with raised trackbar attachment.

The red dot is the pinion where the DS attaches to the axle. (More or less, just remember it's off center.)

What do you think the driveshaft does as the axle articulates on both images? Look at he images and ask yourself, so both driveshafts travel through the same amount of space?

Im saying the pinion and driveshaft in the top image shift less side to side as the axle articulates vs the bottom image.

Last edited by Biginboca; 05-23-2016 at 06:14 PM.

#16

JK Jedi

I think this happens on a lot of wranglers people just don't notice it as it is under rare conditions usually going very slow. I did the Rubicon Trail and 6,7 and 8 rated trails in Moab and it was not an issue. I found mine while on the ramp. I notched the corner of the gas tank skid and it has not been an issue. Mine flexes pretty well.

#18

JK Jedi

(Also don't forget the driveshaft doesn't enter the pumpkin in the center. The pinion is off center so driveshaft swings side to side as well as up and down when the axle articulates. This fact is what you are probably overlooking and now you will understand everything, I hope, lol!

#19

JK Super Freak

My driveshaft goes dead center into my pumpkin? The pinion gear is then dead attached to that? I get it moves but i have never in my life heard that driveshafts and axles will move more with a level trackbar. I saw your picture but still am not getting this... I dont have a rear track bar to look at... And my front i cant change to test as it has to be parallel to my drag link.. Many custom crawlers i have seem that did not go double tri ran damn near flat track bars. While clearance was not a problem pinion rotation and movement always is as they run long travel shocks and do not want to bind a u joint.

Not saying the axle moves more with a level trackbar. Saying it moves more when you raise the axle mount. You can also lower the frame mount to level a trackbar and would have less axle shift but your handling would get worse from the lowered roll center. Everything is a trade off. A lot of buggy builds have a lowered frame mount and a raised axle mount with a level trackbar. They are free to do whatever it's all custom, and high speed handling and roll center is not an buggy issue really...lol. Jeep doesn't have a level trackbar from the factory ever wonder why? Give and take there are always trade offs!

I'm just trying to help the OP out. I appreciate you aren't on the same page as me but I don't know how else to explain it. Maybe you should take some drinking straws or a few toothpicks and make a model of the axle and panhard (trackbar) mounts and see how everything moves if you want to grasp it. I'm not sure that you do?

I'll tell you this, it surprised me at first also! But like I said but I got to witness how the geometry reacted the opposite of what I expected and then I had to research and address the consequences which is what I'm trying to share here.

Last edited by Biginboca; 05-24-2016 at 08:41 AM.

#20

JK Freak

Thread Starter

The driveshaft enters offset to the passenger side, not in the center of the pumpkin. This is really basic man just drop yourself behind the back of a JK and look at a JK rear axle, it's plain to see.

Not saying the axle moves more with a level trackbar. Saying it moves more when you raise the axle mount. You can also lower the frame mount to level a trackbar and would have less axle shift but your handling would get worse from the lowered roll center. Everything is a trade off. A lot of buggy builds have a lowered frame mount and a raised axle mount with a level trackbar. They are free to do whatever it's all custom, and high speed handling and roll center is not an buggy issue really...lol. Jeep doesn't have a level trackbar from the factory ever wonder why? Give and take there are always trade offs!

I'm just trying to help the OP out. I appreciate you aren't on the same page as me but I don't know how else to explain it. Maybe you should take some drinking straws or a few toothpicks and make a model of the axle and panhard (trackbar) mounts and see how everything moves if you want to grasp it. I'm not sure that you do?

I'll tell you this, it surprised me at first also! But like I said but I got to witness how the geometry reacted the opposite of what I expected and then I had to research and address the consequences which is what I'm trying to share here.

Not saying the axle moves more with a level trackbar. Saying it moves more when you raise the axle mount. You can also lower the frame mount to level a trackbar and would have less axle shift but your handling would get worse from the lowered roll center. Everything is a trade off. A lot of buggy builds have a lowered frame mount and a raised axle mount with a level trackbar. They are free to do whatever it's all custom, and high speed handling and roll center is not an buggy issue really...lol. Jeep doesn't have a level trackbar from the factory ever wonder why? Give and take there are always trade offs!

I'm just trying to help the OP out. I appreciate you aren't on the same page as me but I don't know how else to explain it. Maybe you should take some drinking straws or a few toothpicks and make a model of the axle and panhard (trackbar) mounts and see how everything moves if you want to grasp it. I'm not sure that you do?

I'll tell you this, it surprised me at first also! But like I said but I got to witness how the geometry reacted the opposite of what I expected and then I had to research and address the consequences which is what I'm trying to share here.