Lifting question & DW

#1

JK Jedi

Thread Starter

Well....I am going to be adding the OME HD Coil Spring lift to my JKU when it arrives here in the next few weeks and I will be doing it myself with a little help from a few friends.

I won't need to add extended shocks my RE monoshocks from my 2" BB will work fine. Also, I have the 2" Bumpstops with this kit.

However, I will be adding JKS rear and front Adj trac bars, Currie Adj. Lower Control Arms, Northridge rear swaybar links.

Hearing about all the Death Wobble issues.... I don't really want to have the DW happen when the wife is driving the kids somewhere.

What are some important steps to ensure I don't get Death Wobble?

Thanks,

Mike

I won't need to add extended shocks my RE monoshocks from my 2" BB will work fine. Also, I have the 2" Bumpstops with this kit.

However, I will be adding JKS rear and front Adj trac bars, Currie Adj. Lower Control Arms, Northridge rear swaybar links.

Hearing about all the Death Wobble issues.... I don't really want to have the DW happen when the wife is driving the kids somewhere.

What are some important steps to ensure I don't get Death Wobble?

Thanks,

Mike

#2

JK Enthusiast

Join Date: Nov 2009

Location: Snohomish,Wa.

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

There are so many different causes for DW that I don't think anyone can say for sure what you can do to prevent it. Its even happened to completely stock Jeeps with less than 1000 miles on them.

Make sure all the suspension is in proper working order.

Make sure the suspension components are properly tightened.

Adjust the front caster after the lift.

Cross your fingers and pray.

Make sure all the suspension is in proper working order.

Make sure the suspension components are properly tightened.

Adjust the front caster after the lift.

Cross your fingers and pray.

#3

JK Super Freak

^^I totally agree, and the extra stuff you are getting (Trackbars, CA's) will make it even less likely of DW if you get everything on correctly. You should be good

#4

Get a good torque wrench and make sure all of the suspension components are torqued down to the correct specs. This is especially important with the track bar fittings. Torque to 125 lbs with the weight of the JK on the ground.

#5

JK Enthusiast

Join Date: Feb 2009

Location: Carlsbad, NM

Posts: 119

Likes: 0

Received 0 Likes

on

0 Posts

get all of your alignment specs close by eye/anglefinder first. Wait till the springs settle a few miles then get the proper alignment. Just keep the speeds low untill then. Stretch its legs out, take a few speedbumps, get everything settled in. Then get it lined out. All suspensions settle after a bit of driving and will inevitably change your settings some.

#6

JK Jedi

Thread Starter

Thanks guys for the heads up and great advice and awesome write-up planman. I have printed a copy of the picture and write-up and WOL's OME install as well and will complete this lift when I get my bumpers and suspension components.

I was a little nervous doing the lift when I had to start adding the Trac bar and control arms. However, following planman's procedures & notes to ensure less likelihood of DW and..I am not as nervous. So after a few miles and letting the lift settle I should take it in for an alignment? CORRECT?

Good to know about tightening the components with the JK on the ground.

Thanks guys....love this forum!

I was a little nervous doing the lift when I had to start adding the Trac bar and control arms. However, following planman's procedures & notes to ensure less likelihood of DW and..I am not as nervous. So after a few miles and letting the lift settle I should take it in for an alignment? CORRECT?

Good to know about tightening the components with the JK on the ground.

Thanks guys....love this forum!

#7

JK Super Freak

No need to pray and cross fingers.

Death Wobble is no mystery.

It is caused by loose bolts, damaged components, or improper installation.

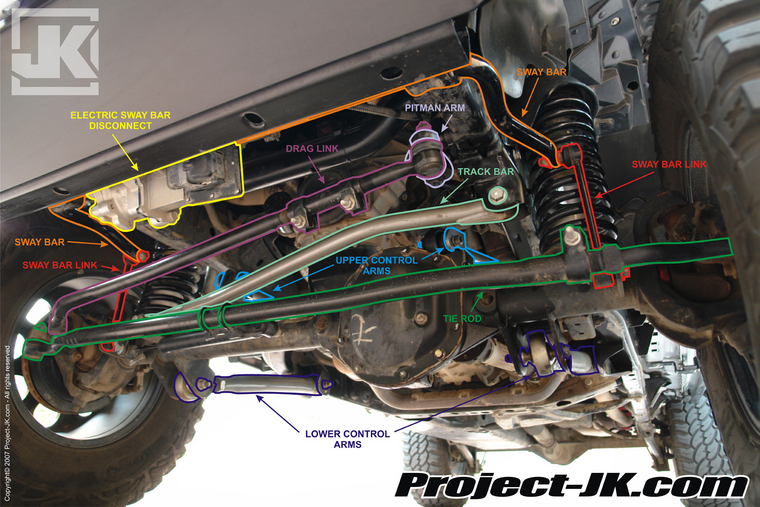

Look at the picture below and follow along:

First, the tie rod (green) has ends that attach to a knuckle on each side. As you could imagine, if either ends of the tie rod were broken or bad, that could be a culprit for a shimmy (not Death Wobble). A common place to damage the tie rod is on the driver's side at the adjusting sleeve (in the picture, just to the right of the red swaybar link). That sleeve (maybe not the correct term for it, but you can see what I am talking about) allows the width of the tie rod to be expanded or contracted. There are threads on that end that can be damaged, causing play on that driver's side and allow an up and down, or circular play movement. Again, this would cause a shimmy, not Death Wobble.

Next, look at the drag link (purple). On one end, it attaches to the pitman arm (lavender), that attaches to the steering gear box. On the other end, the drag link attaches to the passenger side knuckle. When you turn your steering wheel, a shaft turns that goes to the steering gear box. The steering gear box turns the pitman arm, and the pitman arm pushes or pulls the drag link, which pushes or pulls the knuckle. Your steering wheel is straitened by loosening the two nuts on the sleeve/turnbuckle on the drag link and rotating the sleeve/turnbuckle to lengthen or contract the length of the drag link. If either end of the drag link is damaged, this would cause a wobble or shimmy, but not Death Wobble.

Next, look at the trackbar (aqua). It attaches to a bracket on the frame on the driver's side and to the axle on the passenger side. The purpose of the trackbar is to center the axle on the frame. With the axle centered on the frame, it provides some resistance to the steering system to allow you to turn. If there was no trackbar and you turned the steering, the whole front frame would shift. As a result, there is significant force applied to the trackbar in driving and steering.

Now, imagine that the bolts that hold the trackbar are loose in their bolt holes, or that the bolt holes are wallowed out (oval), or that the bushings at the trackbar ends are damaged, or that the bracket at the axle side has come loose because the weld has broken, or that the bushings are all twisted up because the rig has been lifted without the installer loosening the bolts and then retightened them at the new ride height. All these things would allow play in the front trackbar. When you steer or go around a corner, these loose or broken things would allow the axle to shake or slide side to side. If you hit a bump in the road, it could knock the trackbar towards the driver's side. Then, the rest of the suspension (springs, etc.) would try to bring the trackbar back to the passenger side. If you were going at any sort of speed, you could develop a kind of harmonic resonance as the axle more and more violently slide/rocked/shaked from side to side. It would feel like your whole front end was being voilently torn apart. You would have to bring your vehicle to a complete standstill to stop the harmonic resonance. This is Death Wobble.

Even one incident of violent Death Wobble related to the front trackbar can cause significant damage. The voilent harmonic resonance of the back and forth shaking is more than the trackbar bushings, bolt holes, and brackets are designed to handle. A severe Death Wobble occurance can crack or break the welds on the axle side trackbar bracket, or the bolt can wallow out the bolt hole in the bracket, or the bushing can be permanently damaged.

This is the most common source of Death Wobble because inexperienced installers either do not remove the bolt from the trackbar when they install a lift--leaving the bushing pinched in the bracket and bound up, or they do not properly torque the bolts after the lift has been installed with the tires on and the full weight of the vehicle on the ground at ride height, or (maybe the most common) they do not retorque the trackbar bolts after the first 50 miles, after every heavy wheeling trip, and at every oil change interval.

Next, look at the lower control arms (purple) and the upper control arms (light blue). In the picture, they are aftermarket arms with a heim joint on one end. However, the stock control arms have a rubber bushing at each end. When the control arms are properly torqued, the bushing is somewhat pinched in the mounting brackets on the axle and the frame. Sometimes, an installer will make the mistake of not loosening the bolts for the control arms when they install a lift. What happens sometimes is they really bind up the bushings because they are pinched/sandwiched at stock ride height, but then forced to the new lifted ride height. These bound up bushings can cause weird handling, bushing failure, and lead to Death Wobble. The proper way is to loosen the bolts, install the lift, reinstall the wheels so the suspension and jeep are at the new ride height, rock the vehicle/suspension back and forth and side to side, then re-torque the bolts to spec, then after 50 miles re-torque them to spec, then after every oil change or very heavy wheeling trip re-torque them to spec.

Improperly balanced tires, too much air in tires, bent wheels, improperly installed wheel spacers, bad tires (with separated plys), and poor alignment specs (caster, camber, and not enough toe-in) can cause wobbles and shimmies that lead to Death Wobble. However, these precipitate Death Wobble, but they are not the cause of Death Wobble.

Although not specifically identified in the picture, the ball joints that are at the top and bottom of each knuckle where it attaches to the axle C can go bad. Bad ball joints can cause shimmies, wobbles, but usually not full on Death Wobble.

Next, allthough not identified in the picture, the unit bearings can go bad and be a cause of shimmy and wobble, but not Death Wobble.

Hope this helps--assuming you read it all.

Death Wobble is no mystery.

The reason that the steering stabilizer masks it is that it can absorb some of the side to side voilent harmonics of a loose trackbar or damaged mounts. However, this masking is dangerous because it will not prevent the eventual failure of trackbar bracket welds and bolt holes from trackbar Death Wobble.

Death Wobble is no mystery.

It is caused by loose bolts, damaged components, or improper installation.

Look at the picture below and follow along:

First, the tie rod (green) has ends that attach to a knuckle on each side. As you could imagine, if either ends of the tie rod were broken or bad, that could be a culprit for a shimmy (not Death Wobble). A common place to damage the tie rod is on the driver's side at the adjusting sleeve (in the picture, just to the right of the red swaybar link). That sleeve (maybe not the correct term for it, but you can see what I am talking about) allows the width of the tie rod to be expanded or contracted. There are threads on that end that can be damaged, causing play on that driver's side and allow an up and down, or circular play movement. Again, this would cause a shimmy, not Death Wobble.

Next, look at the drag link (purple). On one end, it attaches to the pitman arm (lavender), that attaches to the steering gear box. On the other end, the drag link attaches to the passenger side knuckle. When you turn your steering wheel, a shaft turns that goes to the steering gear box. The steering gear box turns the pitman arm, and the pitman arm pushes or pulls the drag link, which pushes or pulls the knuckle. Your steering wheel is straitened by loosening the two nuts on the sleeve/turnbuckle on the drag link and rotating the sleeve/turnbuckle to lengthen or contract the length of the drag link. If either end of the drag link is damaged, this would cause a wobble or shimmy, but not Death Wobble.

Next, look at the trackbar (aqua). It attaches to a bracket on the frame on the driver's side and to the axle on the passenger side. The purpose of the trackbar is to center the axle on the frame. With the axle centered on the frame, it provides some resistance to the steering system to allow you to turn. If there was no trackbar and you turned the steering, the whole front frame would shift. As a result, there is significant force applied to the trackbar in driving and steering.

Now, imagine that the bolts that hold the trackbar are loose in their bolt holes, or that the bolt holes are wallowed out (oval), or that the bushings at the trackbar ends are damaged, or that the bracket at the axle side has come loose because the weld has broken, or that the bushings are all twisted up because the rig has been lifted without the installer loosening the bolts and then retightened them at the new ride height. All these things would allow play in the front trackbar. When you steer or go around a corner, these loose or broken things would allow the axle to shake or slide side to side. If you hit a bump in the road, it could knock the trackbar towards the driver's side. Then, the rest of the suspension (springs, etc.) would try to bring the trackbar back to the passenger side. If you were going at any sort of speed, you could develop a kind of harmonic resonance as the axle more and more violently slide/rocked/shaked from side to side. It would feel like your whole front end was being voilently torn apart. You would have to bring your vehicle to a complete standstill to stop the harmonic resonance. This is Death Wobble.

Even one incident of violent Death Wobble related to the front trackbar can cause significant damage. The voilent harmonic resonance of the back and forth shaking is more than the trackbar bushings, bolt holes, and brackets are designed to handle. A severe Death Wobble occurance can crack or break the welds on the axle side trackbar bracket, or the bolt can wallow out the bolt hole in the bracket, or the bushing can be permanently damaged.

This is the most common source of Death Wobble because inexperienced installers either do not remove the bolt from the trackbar when they install a lift--leaving the bushing pinched in the bracket and bound up, or they do not properly torque the bolts after the lift has been installed with the tires on and the full weight of the vehicle on the ground at ride height, or (maybe the most common) they do not retorque the trackbar bolts after the first 50 miles, after every heavy wheeling trip, and at every oil change interval.

Next, look at the lower control arms (purple) and the upper control arms (light blue). In the picture, they are aftermarket arms with a heim joint on one end. However, the stock control arms have a rubber bushing at each end. When the control arms are properly torqued, the bushing is somewhat pinched in the mounting brackets on the axle and the frame. Sometimes, an installer will make the mistake of not loosening the bolts for the control arms when they install a lift. What happens sometimes is they really bind up the bushings because they are pinched/sandwiched at stock ride height, but then forced to the new lifted ride height. These bound up bushings can cause weird handling, bushing failure, and lead to Death Wobble. The proper way is to loosen the bolts, install the lift, reinstall the wheels so the suspension and jeep are at the new ride height, rock the vehicle/suspension back and forth and side to side, then re-torque the bolts to spec, then after 50 miles re-torque them to spec, then after every oil change or very heavy wheeling trip re-torque them to spec.

Improperly balanced tires, too much air in tires, bent wheels, improperly installed wheel spacers, bad tires (with separated plys), and poor alignment specs (caster, camber, and not enough toe-in) can cause wobbles and shimmies that lead to Death Wobble. However, these precipitate Death Wobble, but they are not the cause of Death Wobble.

Although not specifically identified in the picture, the ball joints that are at the top and bottom of each knuckle where it attaches to the axle C can go bad. Bad ball joints can cause shimmies, wobbles, but usually not full on Death Wobble.

Next, allthough not identified in the picture, the unit bearings can go bad and be a cause of shimmy and wobble, but not Death Wobble.

Hope this helps--assuming you read it all.

Death Wobble is no mystery.

The reason that the steering stabilizer masks it is that it can absorb some of the side to side voilent harmonics of a loose trackbar or damaged mounts. However, this masking is dangerous because it will not prevent the eventual failure of trackbar bracket welds and bolt holes from trackbar Death Wobble.

As always, great info Planman!

Trending Topics

#8

JK Jedi Master

Planman= Prince of the Puck / Lord of the Budget Boost / The Planmeistermasterplanman / King Tut of the Torque / and now The Duke of Deathwobble.  Hell of a guy, and seems like a smart mofo too! Big thanks for the help you give.

Hell of a guy, and seems like a smart mofo too! Big thanks for the help you give.

Hell of a guy, and seems like a smart mofo too! Big thanks for the help you give.

Hell of a guy, and seems like a smart mofo too! Big thanks for the help you give.

#9

JK Jedi

Thread Starter

Thanks guys.

TripleJeep_99, before you take it in for an alignment, try this write-up first:

http://project-jk.com/jeep-jk-write-...-end-alignment

It is pretty easy to do yourself with the help of a second person.

Then, if it still doesn't feel right, take it in for an alignment to double check things and get a printout of the actual specs.

TripleJeep_99, before you take it in for an alignment, try this write-up first:

http://project-jk.com/jeep-jk-write-...-end-alignment

It is pretty easy to do yourself with the help of a second person.

Then, if it still doesn't feel right, take it in for an alignment to double check things and get a printout of the actual specs.