Dynatrac ProRock 44 build advice

#21

Well, I don't think it, I know it. You have two points that connect to the axle and travel on an arc. As the axle drops, it gets pulled to the driver side because of the arc the track bar travels. If they are not aligned, that means the drag link is traveling on a different arc. Track bar wins and forces movement in the drag link. Basically, it is steering when you aren't asking it to. On a smooth road, not that big of a deal. Get the suspension moving and you will have bump steer. In addition, you will have premature wear of those parts as they are constantly fighting each other.

Not to further complicate this, but from the factory, the angles are slightly different as the drag link and TB are different lengths. They were engineered to intersect at the perfect point on the arc. You don't have that luxury. In addition, there is very little angle stock - the bars are almost parallel to the ground. Therefore, there is very little movement to the side. Think of movement to the side as exponential as you get deeper into the arc. I'd guess your track bar is on a pretty steep angle.

Not to further complicate this, but from the factory, the angles are slightly different as the drag link and TB are different lengths. They were engineered to intersect at the perfect point on the arc. You don't have that luxury. In addition, there is very little angle stock - the bars are almost parallel to the ground. Therefore, there is very little movement to the side. Think of movement to the side as exponential as you get deeper into the arc. I'd guess your track bar is on a pretty steep angle.

#22

That's all well and good, but as I stated, I have no steering issues. The Jeep is not a daily driver, but I have about 400 miles on it since I finished the project, about 75% off road; I really think it tracks better now than it ever has. My draglink is at a 3 degree down angle and the trackbar is at a 12 degree down angle. The only real issue I have at this point is as I stated in another post, if I hit a dip in the road at highway speeds I get a rocking motion that I attribute to the offset spring perches.

With your drag link and track bar off that much, it is borderline dangerous. Your Jeep and your choice.

#23

I agree ^ that feeling you get when you hit a dip in the road is your steering geometry (tracbar and draglink) not on the same plane. They need to be level or parallel to each other. That trac bar needs to be moved to the top hole for proper steering geometry. If the trac bar has figment issues get another trac bar. I run the jks one and it works perfect no fitment issues with the pitman arm or a beefy poison spider diff cover

#24

As noted, your issue is caused by the fact you don't have the track bar and drag link on the same plane. Not doing so introduces a host of handling & steering issues. No way around it, you have to get this right. From your pics I'd agree the track bar needs to be mounted to the top hole on the axle side bracket. Secure it to that point, center the axle under the frame and you should be golden.

The only other issue I could surmise from what you've been saying is that perhaps you don't have the lower control arms set at the proper length. I don't know whether you have a short or long arm kit, but guessing it's a short arm I'd suggest you set the lowers to 23 1/8". This will align the upper & lower bump stops, eliminate virtually all spring bow and prevent component contact. With that done adjust your front uppers to correct caster & pinion angles. Hope this helps.

The only other issue I could surmise from what you've been saying is that perhaps you don't have the lower control arms set at the proper length. I don't know whether you have a short or long arm kit, but guessing it's a short arm I'd suggest you set the lowers to 23 1/8". This will align the upper & lower bump stops, eliminate virtually all spring bow and prevent component contact. With that done adjust your front uppers to correct caster & pinion angles. Hope this helps.

#25

As noted, your issue is caused by the fact you don't have the track bar and drag link on the same plane. Not doing so introduces a host of handling & steering issues. No way around it, you have to get this right. From your pics I'd agree the track bar needs to be mounted to the top hole on the axle side bracket. Secure it to that point, center the axle under the frame and you should be golden.

The only other issue I could surmise from what you've been saying is that perhaps you don't have the lower control arms set at the proper length. I don't know whether you have a short or long arm kit, but guessing it's a short arm I'd suggest you set the lowers to 23 1/8". This will align the upper & lower bump stops, eliminate virtually all spring bow and prevent component contact. With that done adjust your front uppers to correct caster & pinion angles. Hope this helps.

The only other issue I could surmise from what you've been saying is that perhaps you don't have the lower control arms set at the proper length. I don't know whether you have a short or long arm kit, but guessing it's a short arm I'd suggest you set the lowers to 23 1/8". This will align the upper & lower bump stops, eliminate virtually all spring bow and prevent component contact. With that done adjust your front uppers to correct caster & pinion angles. Hope this helps.

#27

It may be a non issue for you as an Offroad rig but it is a major concern on the highway.

#28

You stretched the front. Nothing wrong with that it you do the rest of the work, which is moving the steering box forward or getting a custom track bar.

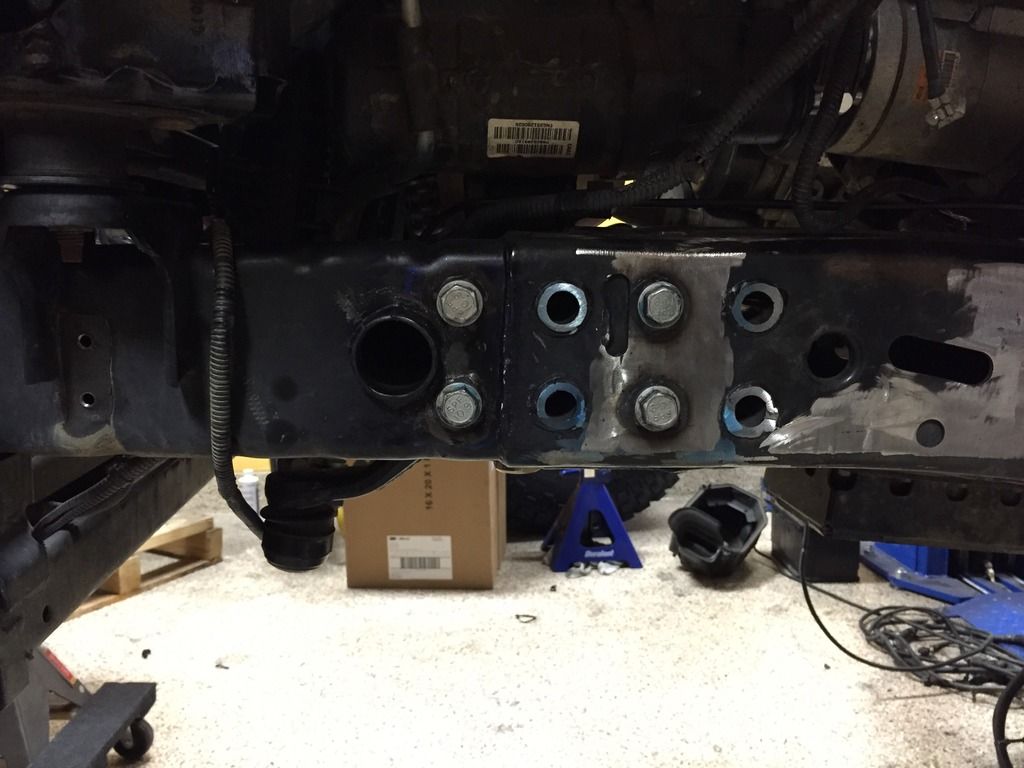

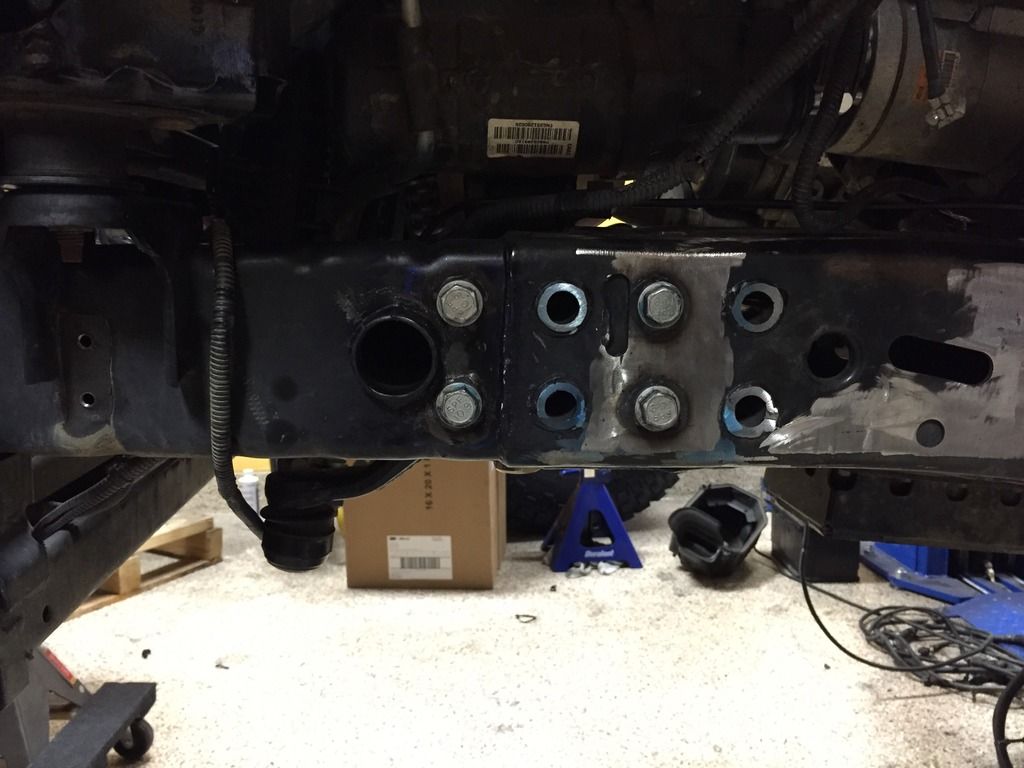

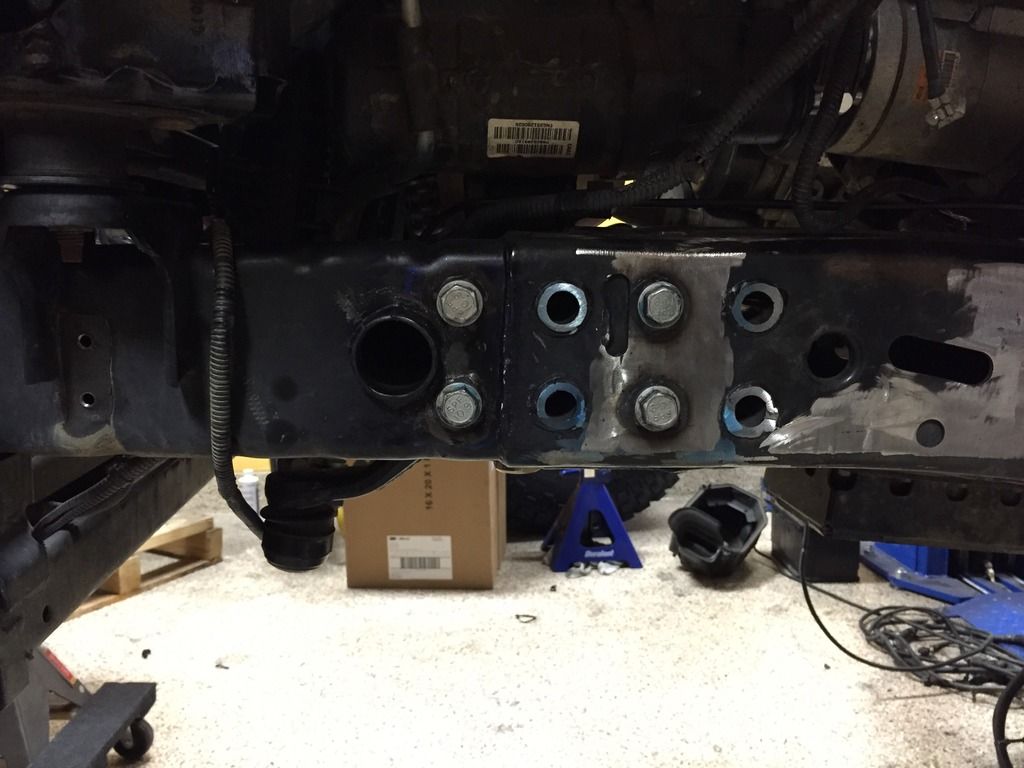

Like so:

#29

As noted above, you have something else going on. Sounds to me like you moved the axle forward. In the stock position, the track bar can't contact the pitman arm.

You stretched the front. Nothing wrong with that it you do the rest of the work, which is moving the steering box forward or getting a custom track bar.

Like so:

You stretched the front. Nothing wrong with that it you do the rest of the work, which is moving the steering box forward or getting a custom track bar.

Like so:

SYNERGY MANUFACTURING :: Jeep JK :: Synergy Jeep JK Front Track Bar & Sector Shaft Brace Kit

#30