The best "daily driver" lift

#41

JK Jedi Master

Join Date: Jan 2008

Location: Austin <--> Colorado Springs

Posts: 11,463

Likes: 0

Received 162 Likes

on

154 Posts

https://www.jk-forum.com/forums/show...-Degree-Wedges

#43

JK-Forum Founder

Join Date: Jul 2006

Location: Laguna Niguel, CA

Posts: 36,534

Likes: 0

Received 16 Likes

on

15 Posts

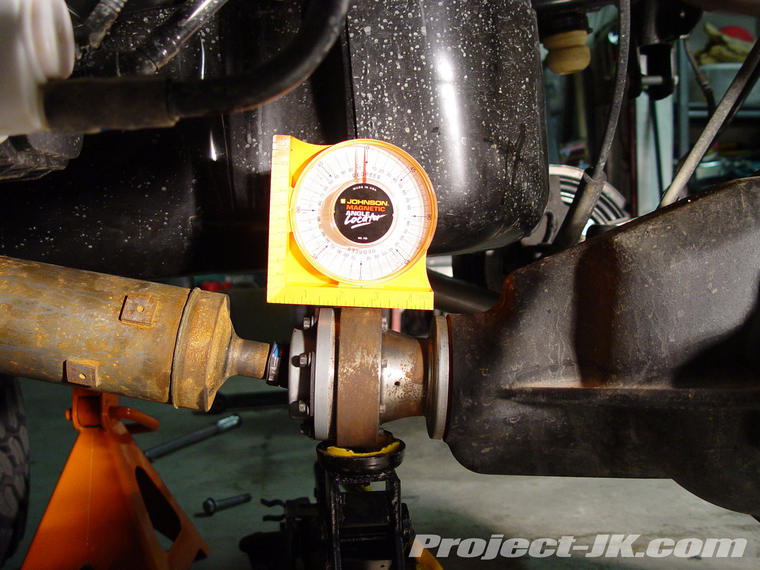

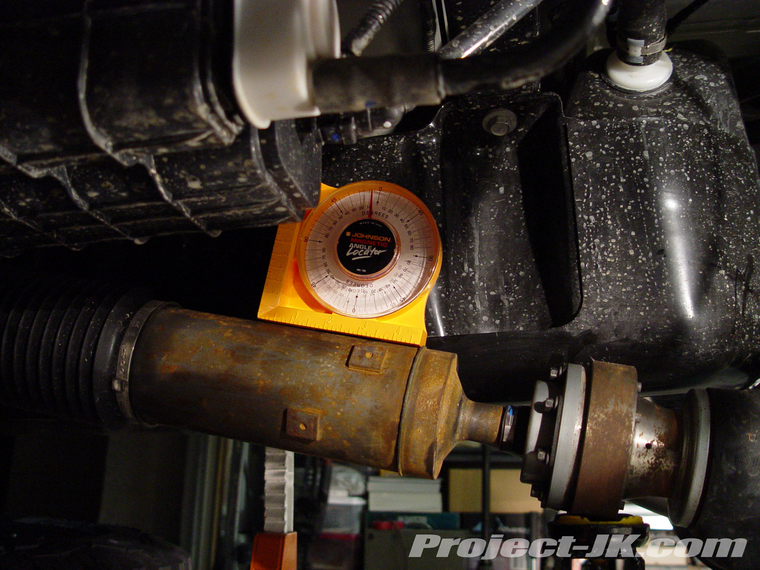

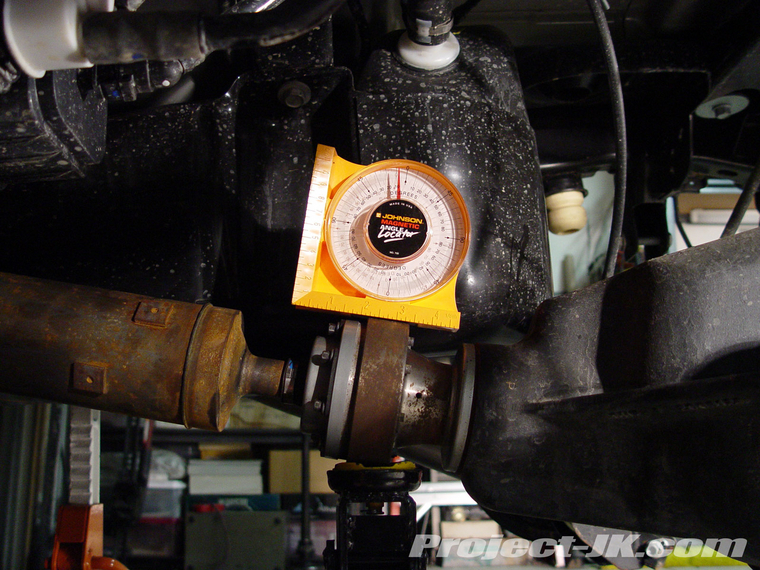

here's what your pinion looks like from the factory - the pinion is parallel to the output shaft...

and, here's what it should look like when installing an aftermarket u-joint style drive shaft...

http://www.northridge4x4.com/proddet...S-2400&cat=273

Last edited by wayoflife; 01-13-2011 at 02:07 PM.

#46

JK Enthusiast

Join Date: Nov 2010

Location: Allentown, Pa

Posts: 164

Likes: 0

Received 0 Likes

on

0 Posts

Aftermarket shafts use different joints, and need different angles. With stock shafts, you want the pinion and the tcase output to be roughly parallel. With aftermarkets, the pinion needs to be pointed up at the tcase. ( go out to Tom Woods driveline, click on the tech info area up top, and look at Geometry 101, you will see some good pics and an explanation)

So, you need some way of 'tilting' the axle enough to get the pinion lined up...

So, you need some way of 'tilting' the axle enough to get the pinion lined up...

I am doing my homework now because I plan on going with a 3" long arm (or short arm) kit. I have a 2 door, so I have to replace the DS so I figure if I am going to do the rear I might I well do the front to. I definitely am going to run 35's but want the ability to run 37's. This means I am going to have to regear. IF I do regear I will go to 5.13. What should I keep in mind with I kit if in the future you might be regearing?

#47

JK-Forum Founder

Join Date: Jul 2006

Location: Laguna Niguel, CA

Posts: 36,534

Likes: 0

Received 16 Likes

on

15 Posts

I am doing my homework now because I plan on going with a 3" long arm (or short arm) kit. I have a 2 door, so I have to replace the DS so I figure if I am going to do the rear I might I well do the front to. I definitely am going to run 35's but want the ability to run 37's. This means I am going to have to regear. IF I do regear I will go to 5.13. What should I keep in mind with I kit if in the future you might be regearing?

#48

JK Super Freak

Join Date: Jun 2009

Location: Westfield, MA

Posts: 1,036

Likes: 0

Received 0 Likes

on

0 Posts

Aftermarket shafts use different joints, and need different angles. With stock shafts, you want the pinion and the tcase output to be roughly parallel. With aftermarkets, the pinion needs to be pointed up at the tcase. ( go out to Tom Woods driveline, click on the tech info area up top, and look at Geometry 101, you will see some good pics and an explanation)

So, you need some way of 'tilting' the axle enough to get the pinion lined up...

So, you need some way of 'tilting' the axle enough to get the pinion lined up...

as mentioned already, with a u-joint style double cardin shaft, you need to set your pinion so that it's relatively parallel to the shaft. you will need adjustable upper control arms to do this.

here's what your pinion looks like from the factory - the pinion is parallel to the output shaft...

and, here's what it should look like when installing an aftermarket u-joint style drive shaft...

it doesn't really effect anything. but, depending on what track bar you have, you may find that the coils make contact with it. the degree wedges work okay but if you really want to address the bowing, i would install a set of JKS adjustable lower spring perches instead.

http://www.northridge4x4.com/proddet...S-2400&cat=273

here's what your pinion looks like from the factory - the pinion is parallel to the output shaft...

and, here's what it should look like when installing an aftermarket u-joint style drive shaft...

it doesn't really effect anything. but, depending on what track bar you have, you may find that the coils make contact with it. the degree wedges work okay but if you really want to address the bowing, i would install a set of JKS adjustable lower spring perches instead.

http://www.northridge4x4.com/proddet...S-2400&cat=273

#49

JK Enthusiast

Join Date: Nov 2010

Location: joplin, mo

Posts: 411

Likes: 0

Received 0 Likes

on

0 Posts