07+ wrangler intermittent wiper fix

#1

The windshield wipers on my 2007 Jeep Wrangler started having problems several months back. At first they would randomly not find home and cycle an extra time or two before they finally stopped. Eventually the home position ended up a few inches up on the windshield instead of at the bottom. Then intermittent on the wiper settings yielded two wipes, then pause. Four wipes, then pause. Seven wipes, then pause etc, etc. Finally intermittent settings yielded continual wiping as if it were on low speed setting. A single wipe command would cause the wiper to stop whenever you released the stalk on the steering column. You had to manually home it or turn the wipers on to get it near home position.

I've worked on electronics involving encoder wheels and sensor flags to indicate "home" positions much like a crank or cam position sensor works, so I figured it was a flag or mechanism of some sort that wasn't working properly. Tonight I removed the wiper motor to see if I could fix the problem. The problem ended up being grease from the worm gear mechanism contaminating some contact fingers.

This takes 30-45 minutes and only requires a few torx bits, a couple sockets, a flathead screwdriver and something to clean up the grease with.

Use you fingers to lift the plastic cap covering the nut securing the wiper arms to the splined studs on the wiping mechanism. Spreading the plastic outwards on the sides allows it to easily pivot up. Remove the 13mm nut holding the wiper arm on the splined stud. Now pivot the wiper arm vertical, and lift it off the splined stud.

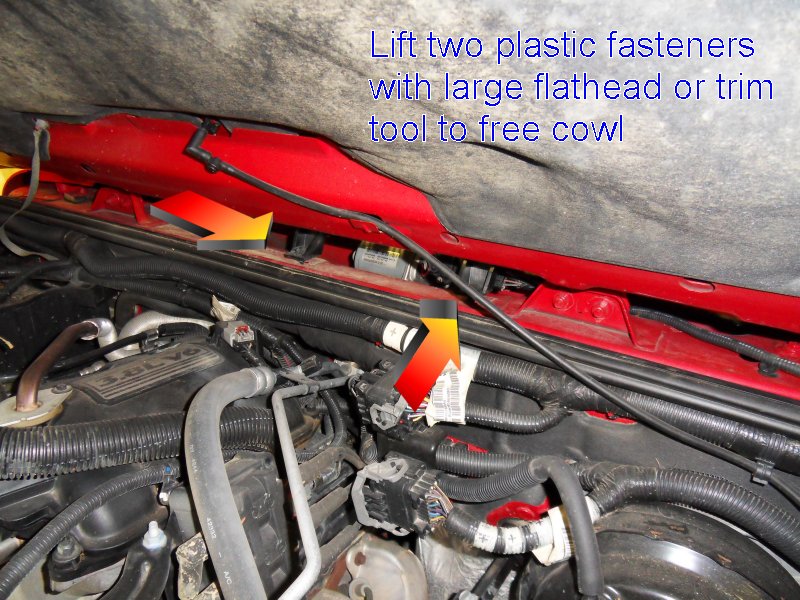

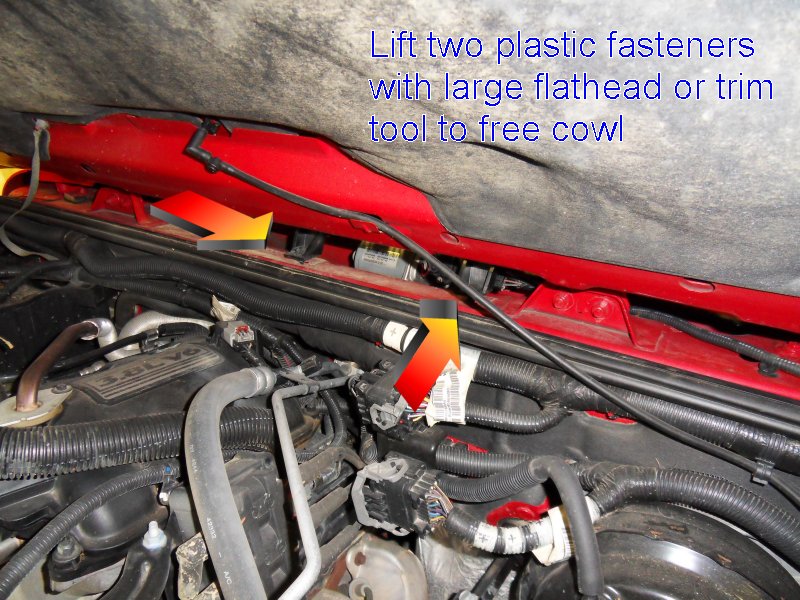

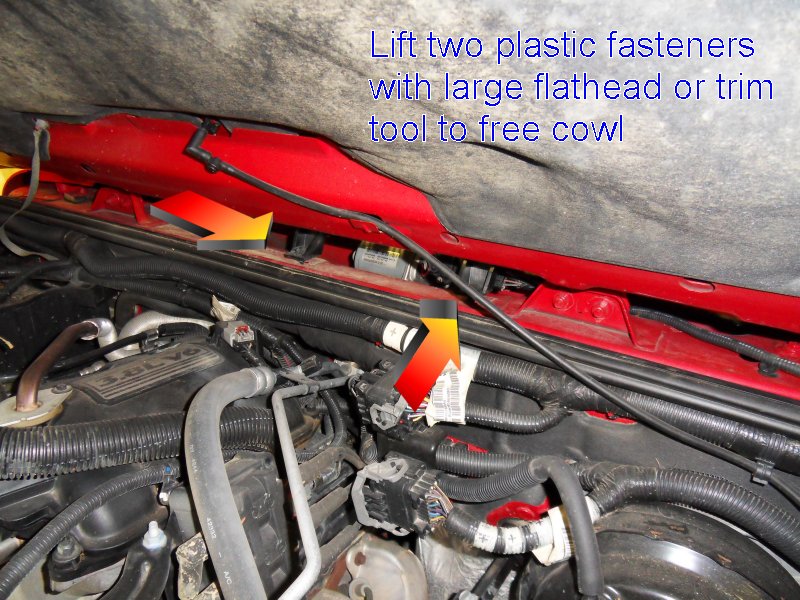

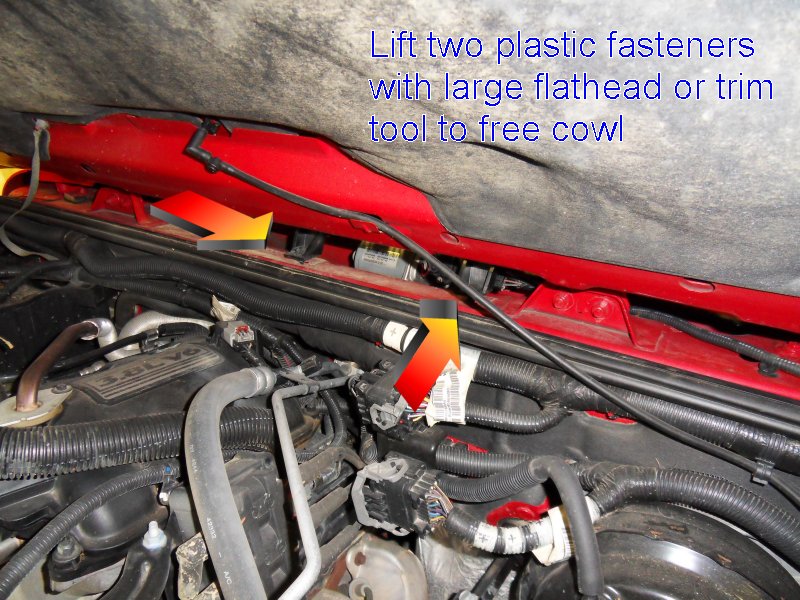

Remove four torx screws holding the cowl down, and then use a large flathead screwdriver to pry up and out the two plastic fasteners securing the screen under the hood. A trim panel tool you can get at Autozone or Advanced will make this easier. Lift the cowl up and then forward to release two plastic feet near the bottom of the windshield. Rotate the back end up and lift off the cowl and plastic screen. Lowering the hood will make this step easier, but it is not necessary.

Disconnect the wiring to the wiper motor by releasing the red plastic lock tab, pressing the catch and pulling. Remove two 10mm bolts holding the wiper assembly to the jeep. Lift the wiper assembly up and out of the cowl area. Note the rubber foot sitting in a hole under the motor.

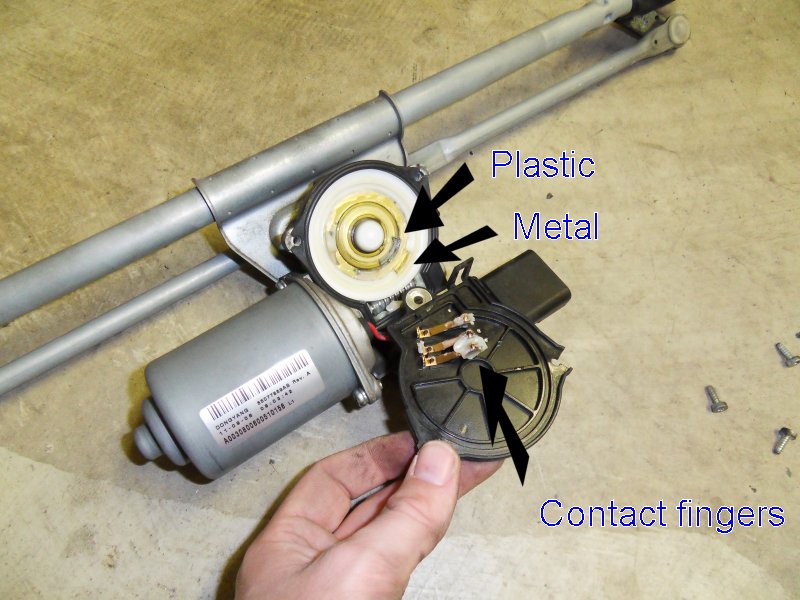

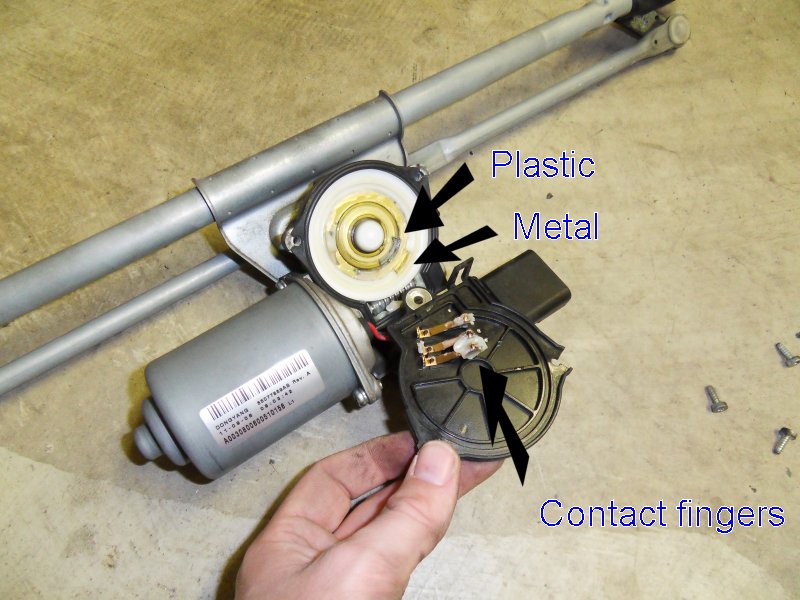

Remove three torx screws holding down the cover on the gears and position indication portion of the motor. Remove the black plastic cover by releasing two plastic catches on the cover. Careful, they are likely brittle and might break.

More views of the wiper motor assembly:

http://www.fawbush.org/images/07_wra...wiperfix_6.JPG

http://www.fawbush.org/images/07_wra...wiperfix_7.JPG

http://www.fawbush.org/images/07_wra...wiperfix_8.JPG

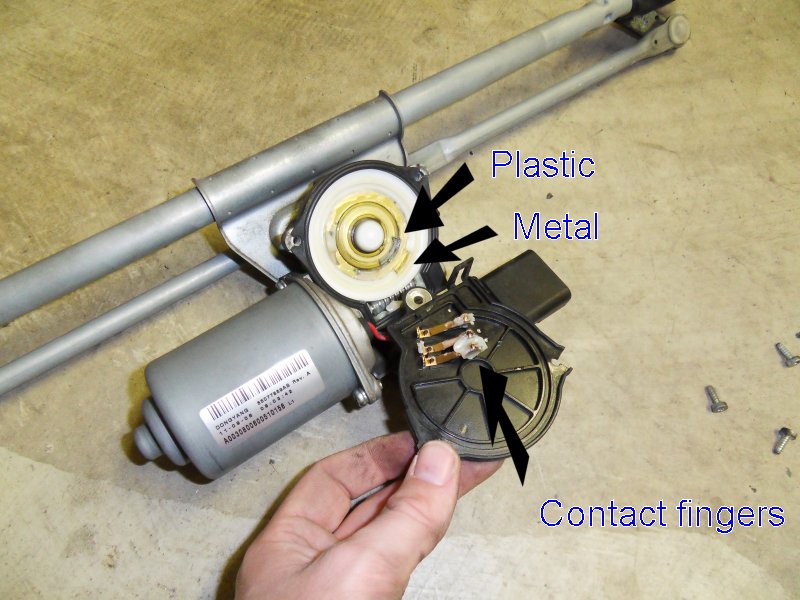

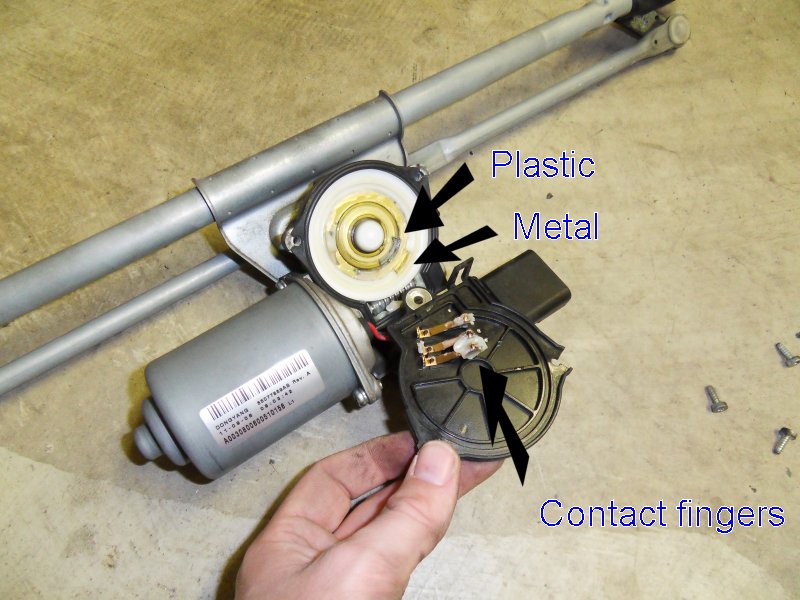

After lifting off the cover you will see how the grease from the worm gear mechanism has contaminated the copper spring fingers which allow the jeeps electronic control module [ECM] to determine wiper arm position.

Clean the face of the metal/plastic disk and the contact fingers. Reassemble in reverse order and the ECM should be able to find home again (for a while).

I've worked on electronics involving encoder wheels and sensor flags to indicate "home" positions much like a crank or cam position sensor works, so I figured it was a flag or mechanism of some sort that wasn't working properly. Tonight I removed the wiper motor to see if I could fix the problem. The problem ended up being grease from the worm gear mechanism contaminating some contact fingers.

This takes 30-45 minutes and only requires a few torx bits, a couple sockets, a flathead screwdriver and something to clean up the grease with.

Use you fingers to lift the plastic cap covering the nut securing the wiper arms to the splined studs on the wiping mechanism. Spreading the plastic outwards on the sides allows it to easily pivot up. Remove the 13mm nut holding the wiper arm on the splined stud. Now pivot the wiper arm vertical, and lift it off the splined stud.

Remove four torx screws holding the cowl down, and then use a large flathead screwdriver to pry up and out the two plastic fasteners securing the screen under the hood. A trim panel tool you can get at Autozone or Advanced will make this easier. Lift the cowl up and then forward to release two plastic feet near the bottom of the windshield. Rotate the back end up and lift off the cowl and plastic screen. Lowering the hood will make this step easier, but it is not necessary.

Disconnect the wiring to the wiper motor by releasing the red plastic lock tab, pressing the catch and pulling. Remove two 10mm bolts holding the wiper assembly to the jeep. Lift the wiper assembly up and out of the cowl area. Note the rubber foot sitting in a hole under the motor.

Remove three torx screws holding down the cover on the gears and position indication portion of the motor. Remove the black plastic cover by releasing two plastic catches on the cover. Careful, they are likely brittle and might break.

More views of the wiper motor assembly:

http://www.fawbush.org/images/07_wra...wiperfix_6.JPG

http://www.fawbush.org/images/07_wra...wiperfix_7.JPG

http://www.fawbush.org/images/07_wra...wiperfix_8.JPG

After lifting off the cover you will see how the grease from the worm gear mechanism has contaminated the copper spring fingers which allow the jeeps electronic control module [ECM] to determine wiper arm position.

Clean the face of the metal/plastic disk and the contact fingers. Reassemble in reverse order and the ECM should be able to find home again (for a while).

The following users liked this post:

karls10jk (03-03-2019)

#2

Good detective work there! So I take it this resolved your problem? Cause at first I thought that was dielectric grease that was suppose to be on those contact surfaces. But if that fixed your problem, I'll know what to do in the event the same thing happens to me or someone else.

#3

Yes, it fixed the problem immediately. The grease very well may be there to prevent corrosion too, but it also kept the fingers from making good contact with the plate. It appeared very clean and moisture free inside, so the gasket and seal seemed to be working.

#5

I know this is an older thread but gotta say thanks to the OP. my '07 wipers started doing this a couple months ago and is driving me crazy. Thought it may have stemmed from the control arm which I replaced when I added a hard top to my JK. Doing this tomorrow!

#7

Thanks so much for posting this fix. I followed your instructions on Feb 1, 2015 and it worked beautifully. A local dealership wanted to charge me $400 to replace the motor that had supposedly internally shorted. Didn't sound right to me since the motor was still working. I grudgingly paid the $90 diagnostic fee then fixed it myself. The one thing I did differently was to only remove the excess grease from the contact fingers - I didn't wipe the grease off of the disk.

Update: Dealership service department says that they can't open the cover to clean the grease off the contacts since it's part of the motor assembly. I guess they can't service - only replace. Expensive replacement when the repair is so simple. The two new plastic fasteners cost me about four bucks apiece!

Update: Dealership service department says that they can't open the cover to clean the grease off the contacts since it's part of the motor assembly. I guess they can't service - only replace. Expensive replacement when the repair is so simple. The two new plastic fasteners cost me about four bucks apiece!

Last edited by Cro; 02-02-2015 at 12:09 PM. Reason: Added update

Trending Topics

#8

Thanks so much for posting this fix. I followed your instructions on Feb 1, 2015 and it worked beautifully. A local dealership wanted to charge me $400 to replace the motor that had supposedly internally shorted. Didn't sound right to me since the motor was still working. I grudgingly paid the $90 diagnostic fee then fixed it myself. The one thing I did differently was to only remove the excess grease from the contacts fingers - I didn't wipe the grease off of the disk.

#9

The windshield wipers on my 2007 Jeep Wrangler started having problems several months back. At first they would randomly not find home and cycle an extra time or two before they finally stopped. Eventually the home position ended up a few inches up on the windshield instead of at the bottom. Then intermittent on the wiper settings yielded two wipes, then pause. Four wipes, then pause. Seven wipes, then pause etc, etc. Finally intermittent settings yielded continual wiping as if it were on low speed setting. A single wipe command would cause the wiper to stop whenever you released the stalk on the steering column. You had to manually home it or turn the wipers on to get it near home position.

I've worked on electronics involving encoder wheels and sensor flags to indicate "home" positions much like a crank or cam position sensor works, so I figured it was a flag or mechanism of some sort that wasn't working properly. Tonight I removed the wiper motor to see if I could fix the problem. The problem ended up being grease from the worm gear mechanism contaminating some contact fingers.

This takes 30-45 minutes and only requires a few torx bits, a couple sockets, a flathead screwdriver and something to clean up the grease with.

Use you fingers to lift the plastic cap covering the nut securing the wiper arms to the splined studs on the wiping mechanism. Spreading the plastic outwards on the sides allows it to easily pivot up. Remove the 13mm nut holding the wiper arm on the splined stud. Now pivot the wiper arm vertical, and lift it off the splined stud.

Remove four torx screws holding the cowl down, and then use a large flathead screwdriver to pry up and out the two plastic fasteners securing the screen under the hood. A trim panel tool you can get at Autozone or Advanced will make this easier. Lift the cowl up and then forward to release two plastic feet near the bottom of the windshield. Rotate the back end up and lift off the cowl and plastic screen. Lowering the hood will make this step easier, but it is not necessary.

Disconnect the wiring to the wiper motor by releasing the red plastic lock tab, pressing the catch and pulling. Remove two 10mm bolts holding the wiper assembly to the jeep. Lift the wiper assembly up and out of the cowl area. Note the rubber foot sitting in a hole under the motor.

Remove three torx screws holding down the cover on the gears and position indication portion of the motor. Remove the black plastic cover by releasing two plastic catches on the cover. Careful, they are likely brittle and might break.

More views of the wiper motor assembly:

http://www.fawbush.org/images/07_wra...wiperfix_6.JPG

http://www.fawbush.org/images/07_wra...wiperfix_7.JPG

http://www.fawbush.org/images/07_wra...wiperfix_8.JPG

After lifting off the cover you will see how the grease from the worm gear mechanism has contaminated the copper spring fingers which allow the jeeps electronic control module [ECM] to determine wiper arm position.

Clean the face of the metal/plastic disk and the contact fingers. Reassemble in reverse order and the ECM should be able to find home again (for a while).

I've worked on electronics involving encoder wheels and sensor flags to indicate "home" positions much like a crank or cam position sensor works, so I figured it was a flag or mechanism of some sort that wasn't working properly. Tonight I removed the wiper motor to see if I could fix the problem. The problem ended up being grease from the worm gear mechanism contaminating some contact fingers.

This takes 30-45 minutes and only requires a few torx bits, a couple sockets, a flathead screwdriver and something to clean up the grease with.

Use you fingers to lift the plastic cap covering the nut securing the wiper arms to the splined studs on the wiping mechanism. Spreading the plastic outwards on the sides allows it to easily pivot up. Remove the 13mm nut holding the wiper arm on the splined stud. Now pivot the wiper arm vertical, and lift it off the splined stud.

Remove four torx screws holding the cowl down, and then use a large flathead screwdriver to pry up and out the two plastic fasteners securing the screen under the hood. A trim panel tool you can get at Autozone or Advanced will make this easier. Lift the cowl up and then forward to release two plastic feet near the bottom of the windshield. Rotate the back end up and lift off the cowl and plastic screen. Lowering the hood will make this step easier, but it is not necessary.

Disconnect the wiring to the wiper motor by releasing the red plastic lock tab, pressing the catch and pulling. Remove two 10mm bolts holding the wiper assembly to the jeep. Lift the wiper assembly up and out of the cowl area. Note the rubber foot sitting in a hole under the motor.

Remove three torx screws holding down the cover on the gears and position indication portion of the motor. Remove the black plastic cover by releasing two plastic catches on the cover. Careful, they are likely brittle and might break.

More views of the wiper motor assembly:

http://www.fawbush.org/images/07_wra...wiperfix_6.JPG

http://www.fawbush.org/images/07_wra...wiperfix_7.JPG

http://www.fawbush.org/images/07_wra...wiperfix_8.JPG

After lifting off the cover you will see how the grease from the worm gear mechanism has contaminated the copper spring fingers which allow the jeeps electronic control module [ECM] to determine wiper arm position.

Clean the face of the metal/plastic disk and the contact fingers. Reassemble in reverse order and the ECM should be able to find home again (for a while).

#10

NOTE: If you are testing, the bottom screw is the GROUND. Make sure at least this screw is in before testing or the wipers won't work.

This fixed my 2012 rubicon with wipers not turning off right away and intermittent function not working.

ALSO, if you have wipers going on by themselves and/or other crazy electrical issues, UNPLUG the sway bar disconnect (rubicons only). The CANBUS is shorting out and causing these issues. This was not a TIPM module issue, have not done anything to mine.

This fixed my 2012 rubicon with wipers not turning off right away and intermittent function not working.

ALSO, if you have wipers going on by themselves and/or other crazy electrical issues, UNPLUG the sway bar disconnect (rubicons only). The CANBUS is shorting out and causing these issues. This was not a TIPM module issue, have not done anything to mine.

Last edited by bcpaul; 03-15-2023 at 10:23 AM.