Scorpicon's Bolt-On Build Thread

#1

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

Hey Everyone! Finally got around to making my build thread for the 2013 Dune JKU Rubicon, named Scorpicon, that I ordered and received just over a month ago.

This will be a SLOW build, but I will lay out my plan in phases below, that I hope and plan to get me on 40's and 1-tons by the end(within 2 years). I attempted to do this build last year, and shortly after I began to purchase parts I determined I wanted to perform the build on a 2013 JKUR. The determining factor was the new(2012+) 3.6L, rather than my 2007 JKU Sahara with the slug of a 3.8L. And while doing so, I determined a Rubicon would be a better choice for the sway bar, transfer case, lockers, 4.10 stock option gears, etc. This, combined with traveling for work put a temporary hold on my build, but I am now back on track.

Again, this will be a somewhat slow build due to funds, and access to a garage and tools, but the plan remains the same. So bare with me and give me ANY advice you may be able to give in the product and parts I am looking to purchase! Items in red are already purchased items.

Phase-1

•Drag link flip

•Adjustible Track Bar - JKS Gen II Bar

•1350 Front and Rear Drive Shafts

•Adjustable Front Lower Control Arms - Rock Krawler High Clearance Arms

•Skid system - EVO MFG Full ProTek Skid System

•Flat fender flares - Stock Fender Cut

•4 door Sliders - LOD Signiture Series Sliders

•Bolt on Coilover system - EVO MFG Front and Rear

•Winch Mount Stubby Bumper - EVO MFG 1/4 pounder

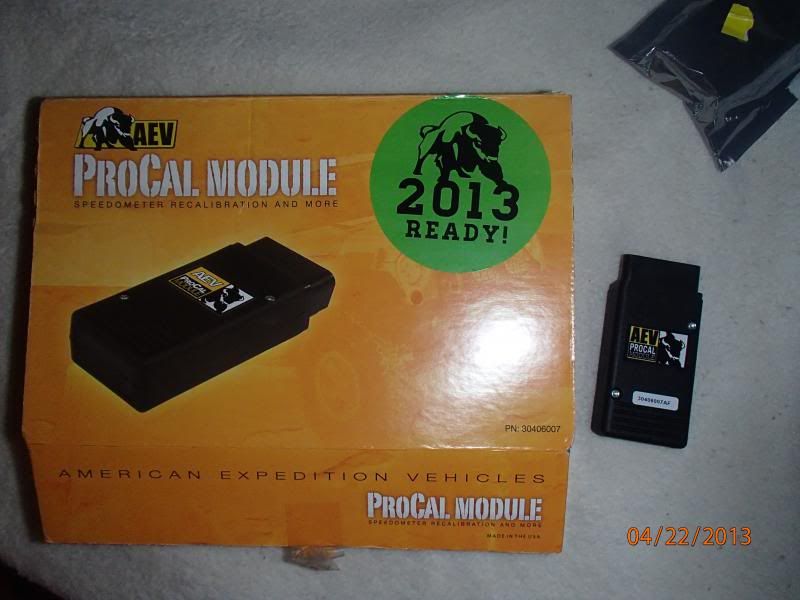

•Speedometer recalibration/Tuner - AEV Procal

•Recovery Gear

•High lift jack

•CB Radio, antenna, and wiring

•35”x17” MT tires - Nitto Mud Grappler 35x12.50r17

•Rear Tire carrier (with or w/o bumper) - OR-Fab Jerry Can Carrier

•Wheel Spacers - 1.5" Spidertrax

•Inner C-gussets - EVO MFG C2 Gussets

Phase-2

•Bolt-on Long Arm bracketry and control arms

•Electrical wiring system with dash or a-pillar rocker switches

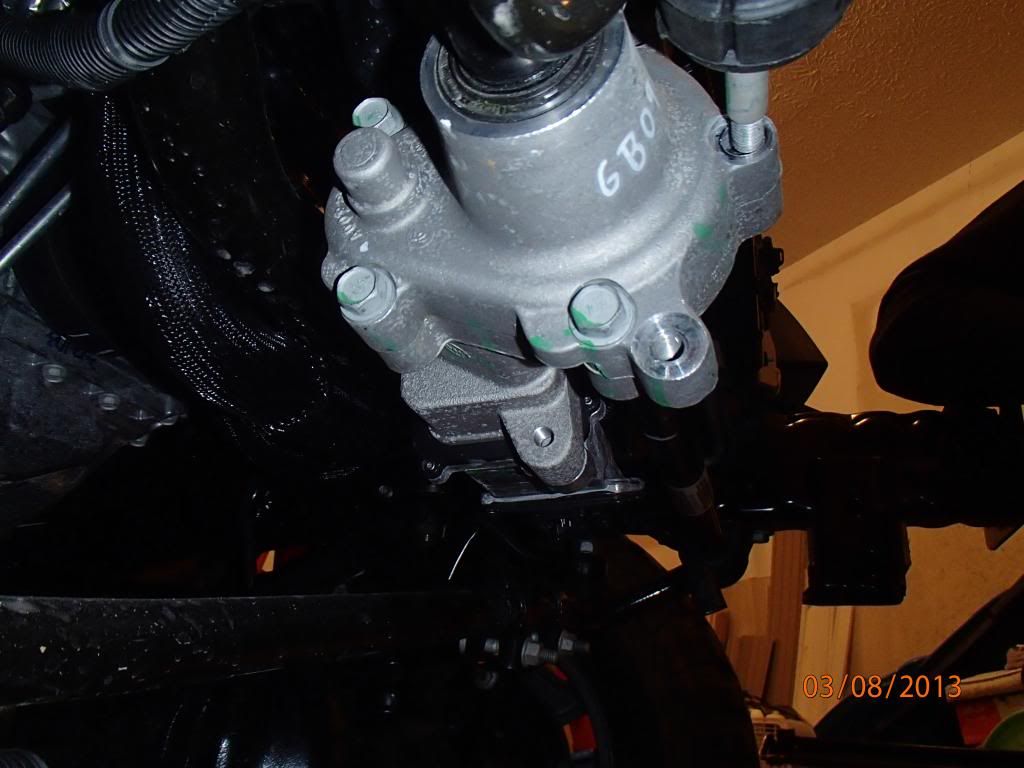

•Hydraulic Assist Steering

•Onboard Air System

•LED Off Road Lighting - OUTLAW LED (2)-2x2 A-pillars and (1) 20" Two row light bar

•9.5-12K Winch - Warn 9.5ti

•Cat Back Exhaust - DynoMax Evolution Competition Series Exhaust

•CAI System

•Air Bump-stops

•Soft Top - Bestop Trektop NX Diamond Series

Phase-3

•1 ton axles with 5.13's, 8 on 6.5 lug, ARB, full float rear

•Beadlock 17” 8on6.5 wheels - ATX Slabs

•40” x 17” tires

•Sport cage

•Power steering cooler

•4 point Racing Seats

This will be a SLOW build, but I will lay out my plan in phases below, that I hope and plan to get me on 40's and 1-tons by the end(within 2 years). I attempted to do this build last year, and shortly after I began to purchase parts I determined I wanted to perform the build on a 2013 JKUR. The determining factor was the new(2012+) 3.6L, rather than my 2007 JKU Sahara with the slug of a 3.8L. And while doing so, I determined a Rubicon would be a better choice for the sway bar, transfer case, lockers, 4.10 stock option gears, etc. This, combined with traveling for work put a temporary hold on my build, but I am now back on track.

Again, this will be a somewhat slow build due to funds, and access to a garage and tools, but the plan remains the same. So bare with me and give me ANY advice you may be able to give in the product and parts I am looking to purchase! Items in red are already purchased items.

Phase-1

•Drag link flip

•Adjustible Track Bar - JKS Gen II Bar

•1350 Front and Rear Drive Shafts

•Adjustable Front Lower Control Arms - Rock Krawler High Clearance Arms

•Skid system - EVO MFG Full ProTek Skid System

•Flat fender flares - Stock Fender Cut

•4 door Sliders - LOD Signiture Series Sliders

•Bolt on Coilover system - EVO MFG Front and Rear

•Winch Mount Stubby Bumper - EVO MFG 1/4 pounder

•Speedometer recalibration/Tuner - AEV Procal

•Recovery Gear

•High lift jack

•CB Radio, antenna, and wiring

•35”x17” MT tires - Nitto Mud Grappler 35x12.50r17

•Rear Tire carrier (with or w/o bumper) - OR-Fab Jerry Can Carrier

•Wheel Spacers - 1.5" Spidertrax

•Inner C-gussets - EVO MFG C2 Gussets

Phase-2

•Bolt-on Long Arm bracketry and control arms

•Electrical wiring system with dash or a-pillar rocker switches

•Hydraulic Assist Steering

•Onboard Air System

•LED Off Road Lighting - OUTLAW LED (2)-2x2 A-pillars and (1) 20" Two row light bar

•9.5-12K Winch - Warn 9.5ti

•Cat Back Exhaust - DynoMax Evolution Competition Series Exhaust

•CAI System

•Air Bump-stops

•Soft Top - Bestop Trektop NX Diamond Series

Phase-3

•1 ton axles with 5.13's, 8 on 6.5 lug, ARB, full float rear

•Beadlock 17” 8on6.5 wheels - ATX Slabs

•40” x 17” tires

•Sport cage

•Power steering cooler

•4 point Racing Seats

Last edited by StrizzyChris; 06-13-2013 at 02:41 PM.

#2

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

This is a copy and past from my last build thread. Some of it has changed, but much remains the same. I am being a little more realistic this time in the timeframe that I'll be able to perform this build. It'll be over 1-2 years(hopefully no more) rather than a couple of months like planned/desired before.

The purpose of this thread is to have fun. I will use it to keep the build on track and to hold myself accountable for the build. I also hope it serves as a source of information to other people that are new to Building Big!

Just like many other threads, my continued posts will be pics and info of the build. I will post complications encountered, and solutions to those snags, in as much detail as possible. Please feel free to chime in with recommendations, possible complications I should prepare for! Thanks for reading guys!

Buliding Background

So when I purchased my JK, I knew I couldn’t wait to get it topless, go for a cruise on the weekends, and every other spare chance I got. I imagined taking it down in the creek beds and hill sides of my Southern Ohio home town. I have been around fairly stock jeeps my entire life. The majority of add-ons I have helped with were slightly larger than stock MT tires and VERY mild bolt on lifts. These jeeps were a great time and capable of taking me many of the places I wanted to go. Theeeeeeeeen came my JK.

My original plans were to build it like all the old jeeps I’ve always been in and around. Keep it near stock, place a little bit of money in suspension upgrades, go with 33”-35” tires, and install a mild lift. I then found online forums. They sucked me in with numbers, specs, and possibilities. I read and watching people with these insane (in my mind at the time) lift systems that were capable of running 37”, 40”, and even 42” tires. I couldn’t quit reading of the changes they made to accommodate these upgrades.

Then came all the horror stories and failures from improperly building their rig for the functions they wanted it to perform. Many of these failures were due to shotty aftermarket kits and parts that were built for looks and not function. Many were from going too big on a budget and breaking parts (i.e. Axle tubes or inner knuckles) they could have saved by taking their time and “building it backwards”.

Building it Backwards

As I continued to read I realized that to properly build my rig, I needed to consider the next part “upstream”. Larger tires place stress on the knuckles and axle tubes. They often require an upgrade in gearing to make up for the loss in torque and fuel economy. A lift system (that is lacking proper components) will misalign the track bars, drive shafts, draglink, etc.

Then you will have to think of all the future added weight. Add a sport cage, heavy bumpers, winch, roof rack, heavy full sized spare tire, etc. and you will place added strain on these components that weren't designed for extreme use.

My original thoughts of 33”-35” tires went quickly to 37’s. I started to think out the build and my mind began flirtting with the possibility of 40’s. I know myself all too well, and that I will later regret not building it capable of handling bigger. I also know that I hate to spend money twice! I then made my mind up to build it for the magic number 40!

Building it Bolt-on

I looked at the required components to make an extremely reliable rig and the numbers started to add up. I knew I wanted a Long Arm lift and began noticing that there were MANY good lift systems. Some were bolt-on and some were weld on…..(disclaimer--> I know how to wrench but when it comes to welding and electrical work, my skills are TREMENDOUSLY sub-par. So for anything weld on I would require a professional’s assistance)

I next began contacting shops and quickly realized the labor cost involved in installing the weld on lift kits would range up to and even over $2,500. That’s sometimes more than the cost of the lift itself!!! I could buy my front and rear bumpers with a winch for $2,500!!! Then you factor in other components and you quickly see the cost of install adding up.

This has driven me to research my build for a year. I want to build the best rig I can, while taking all the money saved from installation and reinvesting it into upgraded, more capable, parts.

The purpose of this thread is to have fun. I will use it to keep the build on track and to hold myself accountable for the build. I also hope it serves as a source of information to other people that are new to Building Big!

Just like many other threads, my continued posts will be pics and info of the build. I will post complications encountered, and solutions to those snags, in as much detail as possible. Please feel free to chime in with recommendations, possible complications I should prepare for! Thanks for reading guys!

Buliding Background

So when I purchased my JK, I knew I couldn’t wait to get it topless, go for a cruise on the weekends, and every other spare chance I got. I imagined taking it down in the creek beds and hill sides of my Southern Ohio home town. I have been around fairly stock jeeps my entire life. The majority of add-ons I have helped with were slightly larger than stock MT tires and VERY mild bolt on lifts. These jeeps were a great time and capable of taking me many of the places I wanted to go. Theeeeeeeeen came my JK.

My original plans were to build it like all the old jeeps I’ve always been in and around. Keep it near stock, place a little bit of money in suspension upgrades, go with 33”-35” tires, and install a mild lift. I then found online forums. They sucked me in with numbers, specs, and possibilities. I read and watching people with these insane (in my mind at the time) lift systems that were capable of running 37”, 40”, and even 42” tires. I couldn’t quit reading of the changes they made to accommodate these upgrades.

Then came all the horror stories and failures from improperly building their rig for the functions they wanted it to perform. Many of these failures were due to shotty aftermarket kits and parts that were built for looks and not function. Many were from going too big on a budget and breaking parts (i.e. Axle tubes or inner knuckles) they could have saved by taking their time and “building it backwards”.

Building it Backwards

As I continued to read I realized that to properly build my rig, I needed to consider the next part “upstream”. Larger tires place stress on the knuckles and axle tubes. They often require an upgrade in gearing to make up for the loss in torque and fuel economy. A lift system (that is lacking proper components) will misalign the track bars, drive shafts, draglink, etc.

Then you will have to think of all the future added weight. Add a sport cage, heavy bumpers, winch, roof rack, heavy full sized spare tire, etc. and you will place added strain on these components that weren't designed for extreme use.

My original thoughts of 33”-35” tires went quickly to 37’s. I started to think out the build and my mind began flirtting with the possibility of 40’s. I know myself all too well, and that I will later regret not building it capable of handling bigger. I also know that I hate to spend money twice! I then made my mind up to build it for the magic number 40!

Building it Bolt-on

I looked at the required components to make an extremely reliable rig and the numbers started to add up. I knew I wanted a Long Arm lift and began noticing that there were MANY good lift systems. Some were bolt-on and some were weld on…..(disclaimer--> I know how to wrench but when it comes to welding and electrical work, my skills are TREMENDOUSLY sub-par. So for anything weld on I would require a professional’s assistance)

I next began contacting shops and quickly realized the labor cost involved in installing the weld on lift kits would range up to and even over $2,500. That’s sometimes more than the cost of the lift itself!!! I could buy my front and rear bumpers with a winch for $2,500!!! Then you factor in other components and you quickly see the cost of install adding up.

This has driven me to research my build for a year. I want to build the best rig I can, while taking all the money saved from installation and reinvesting it into upgraded, more capable, parts.

#3

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

So my first installed Item was the LOD Sliders that I ordered from Northridge. They had an awesome sale around christmas where many vendors were between 15-30% off and almost the whole site was on sale. They seem to run the best deals around that time(at least the last 3 years from what I have observed) They also have free shipping, so combined the prices couldnt be beat. The wait time kind of stunk though and took almost 2 months to get them to me, but it was well worth it!

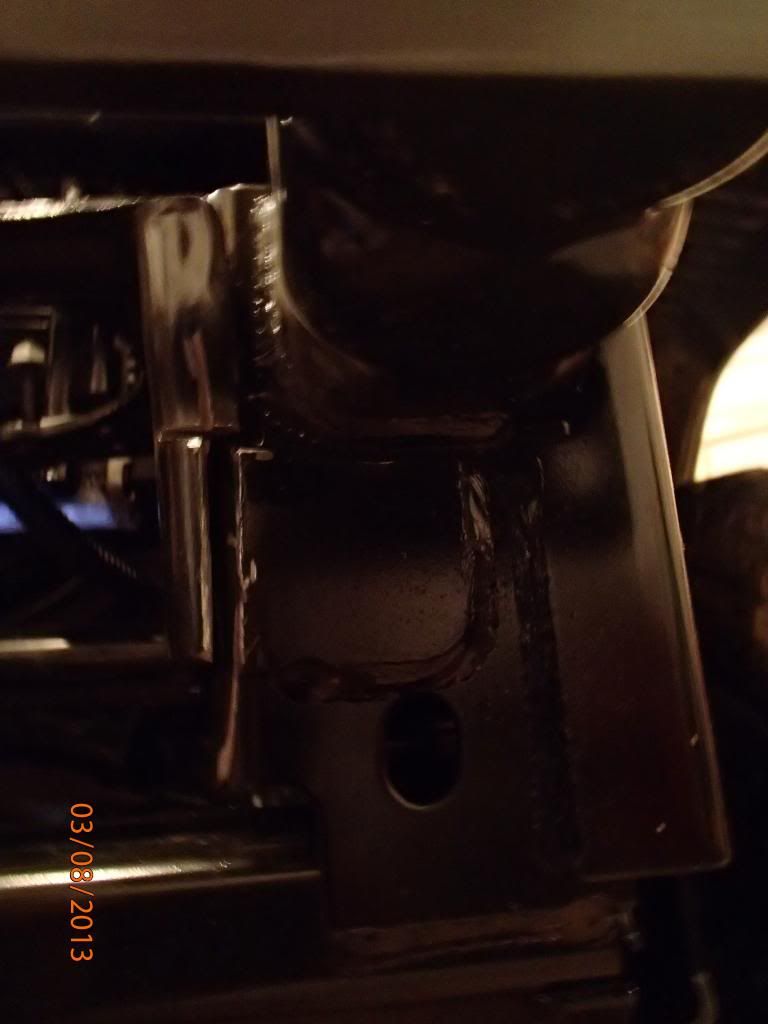

Install was easy. I just removed the stock rock rails. You then slide the sliders up into place for position of final install. You line it up with two existing bolts in the frame where stock belly armor mount to.

You then mark the frame at the spot of the other holes. I used a perm marker.

You'll want to center punch or score the frame to help the drill in starting the frame holes

Next you drill and use some cutting oil. I didnt have any so I used old motor oil to help. My tap for 7/16" bolt says to use a 25/64" drill bit so I had to go out and buy one of those. Also one HUGE WARNING, is to be careful while drilling these holes. I almost snapped my wrist when the drill bit "caught" as it passed through the frame and spun the entire drill. <-Dont say I didnt warn you!

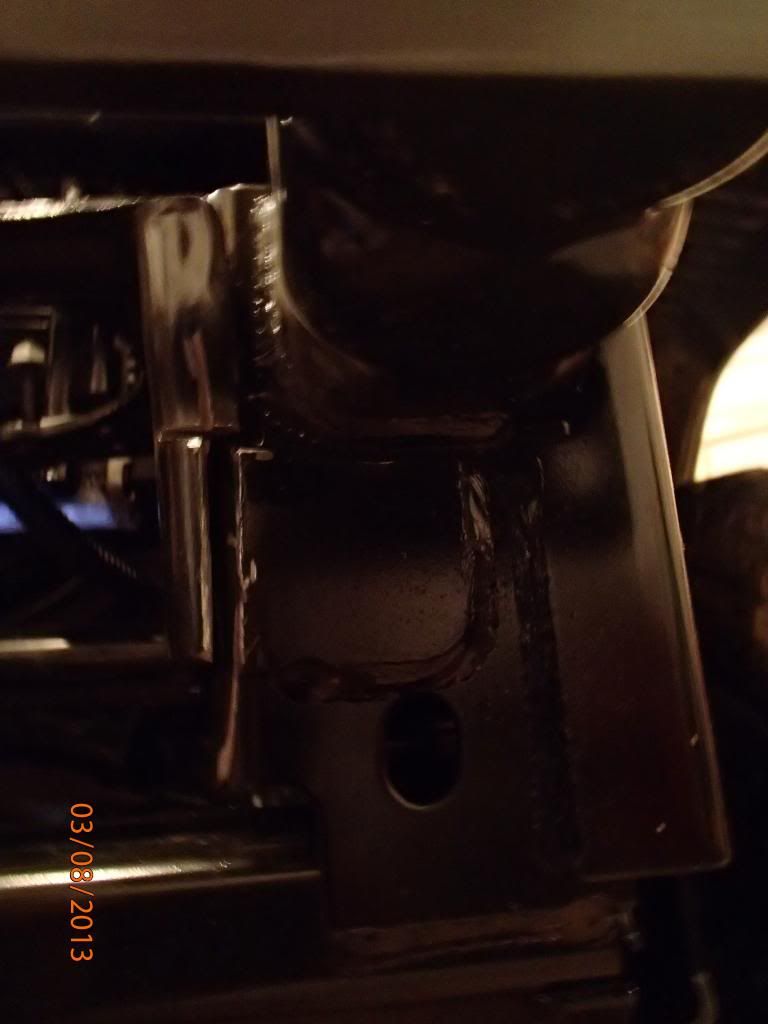

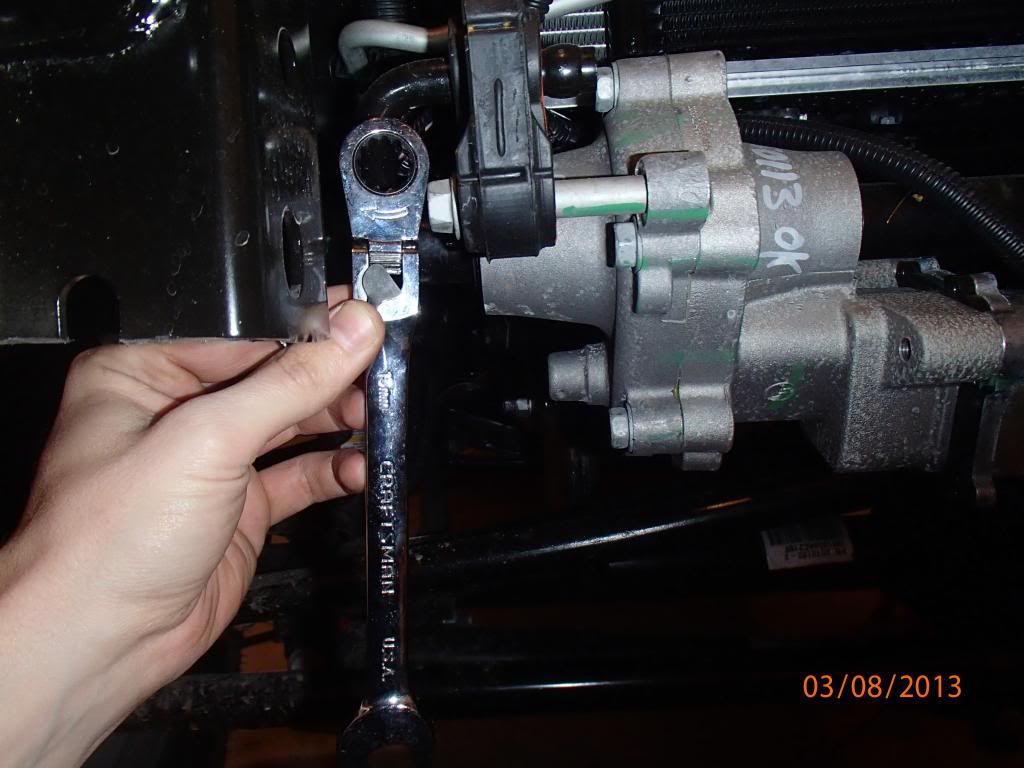

After drilling the hole(I used multiple bits to slowly open the hole to be easier on my bits) you will want to get a 7/16" tap. As you can barely see in the picture, I used an adapter and a socket wrench with the tap due to too little of clearance to spin a standard tap handle.

Then you put the sliders back in place and bolt it on!

There are three guards that are screwed onto the face of the sliders to give it a finished look. I believe the older sliders, these were welded in place. I would consider them optional, but I liked the look.

Pics after installing, during the day, and running through some mud.

Install was easy. I just removed the stock rock rails. You then slide the sliders up into place for position of final install. You line it up with two existing bolts in the frame where stock belly armor mount to.

You then mark the frame at the spot of the other holes. I used a perm marker.

You'll want to center punch or score the frame to help the drill in starting the frame holes

Next you drill and use some cutting oil. I didnt have any so I used old motor oil to help. My tap for 7/16" bolt says to use a 25/64" drill bit so I had to go out and buy one of those. Also one HUGE WARNING, is to be careful while drilling these holes. I almost snapped my wrist when the drill bit "caught" as it passed through the frame and spun the entire drill. <-Dont say I didnt warn you!

After drilling the hole(I used multiple bits to slowly open the hole to be easier on my bits) you will want to get a 7/16" tap. As you can barely see in the picture, I used an adapter and a socket wrench with the tap due to too little of clearance to spin a standard tap handle.

Then you put the sliders back in place and bolt it on!

There are three guards that are screwed onto the face of the sliders to give it a finished look. I believe the older sliders, these were welded in place. I would consider them optional, but I liked the look.

Pics after installing, during the day, and running through some mud.

#4

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

#5

JK Junkie

It's a great carrier. The install is a bit of a pain but it's solid, I've run one for 2 yrs and still no rattles or squeaks.

#6

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

#7

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

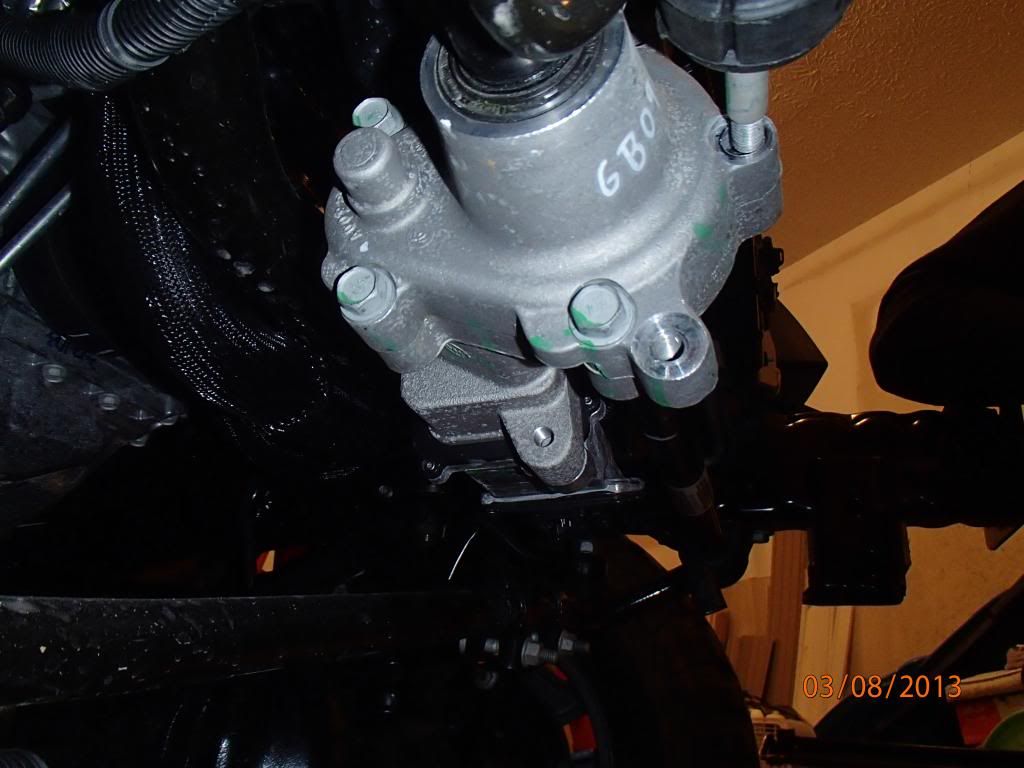

I installed the EVO 1/4 pounder and used the provided instructions. It also shows how to relocate the sway bar motor out of the way due to the high clearance design of their bumper. I must say that the instructions are sufficient, but not completely clear and being black and white makes it even harder to see what they are doing. Took a ton of pics, so I hope this helps supplement their info.

First you will want to remove the front grill to prevent possible damage. You must first disconnect the front turn signals. Slide the red tab away from the signal and then squeeze the release tab.

Next you will want to remove the upper and lower shrouds. The upper, has Philips headed plastic screw securing it. I have always had trouble removing these and I have found the trick of using a self tapping or drywall screw to help in removing these. They wont strip or become damaged by doing this so don't worry.

Next remove your factory fog lights. there are two ways of doing this. Either from the housing and pulling the bulb through like I did or by unplugging it.

The lower shroud is easy to remove from above(or start to remove) by using your screw driver to push the pin through

once everything is completed and dethatched from the bumper, you will now use an 18mm socket to unbolt the bumper from the frame

Next, if you have a 2012+ model Jeep, you will need to remove your vacuum pump. There are two hose attachments and an electrical connection that are easily located. One hose, you will press the green tab away from the connection and pull it directly out. The electrical connection plug has an easy squeeze and release point. Lastly the plain black hose. It is firmly in place and you just pull, very firmly, strait down.

With your pump removed you will now need to cut the pump bracket off. I made two vertical cuts right where the bracket meets the cross bar mount.

Next you will cut off your lower shroud attetchment bar/sway bar guard. These lines just perfectly cleared the bumpers lower edge.

The drivers side of the vehicle has room for moving tools around, but if you have a rubicon, the sway bar motor is tight, and cutting the passenger side rear bar off is difficult. I used the holes in the cross bar to place my pry bar and bend the rear remaining tab for easier cutting access.

If you have a non Rubicon model, Jeep is now ready for the bumper to be installed. I would take this time to clean up your exposed metal areas and paint them to prevent the certain rusting that will fallow otherwise. Also installing your chosen evap relocation kit(2012+ Jeeps) would be a good idea since you have clearance.

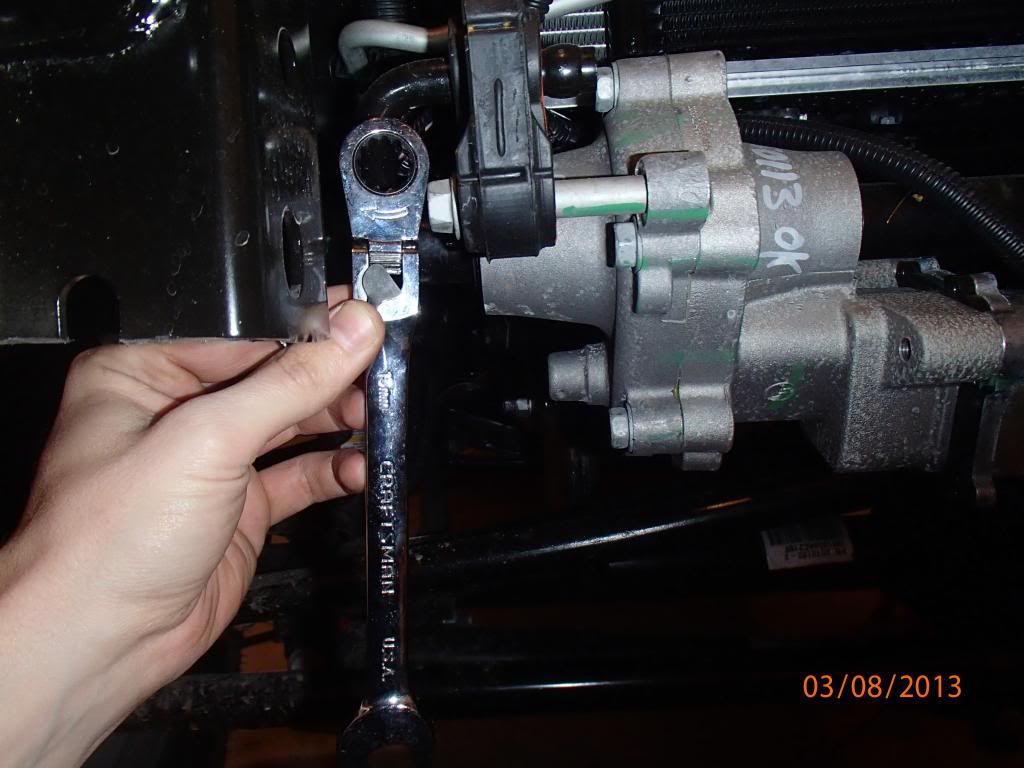

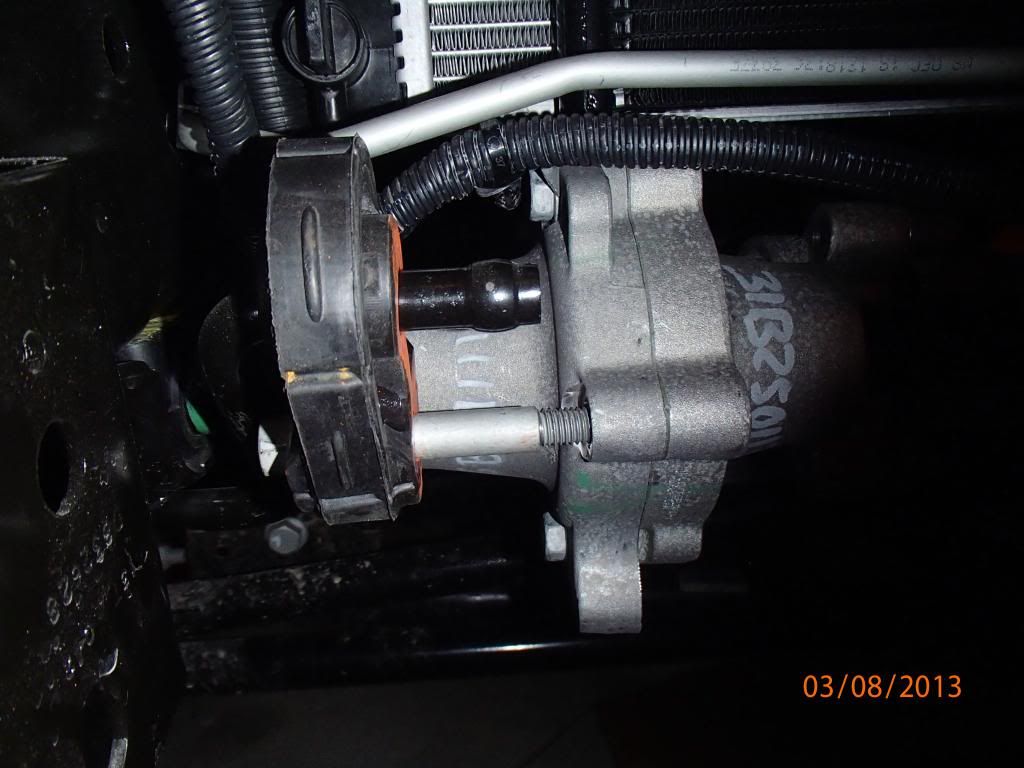

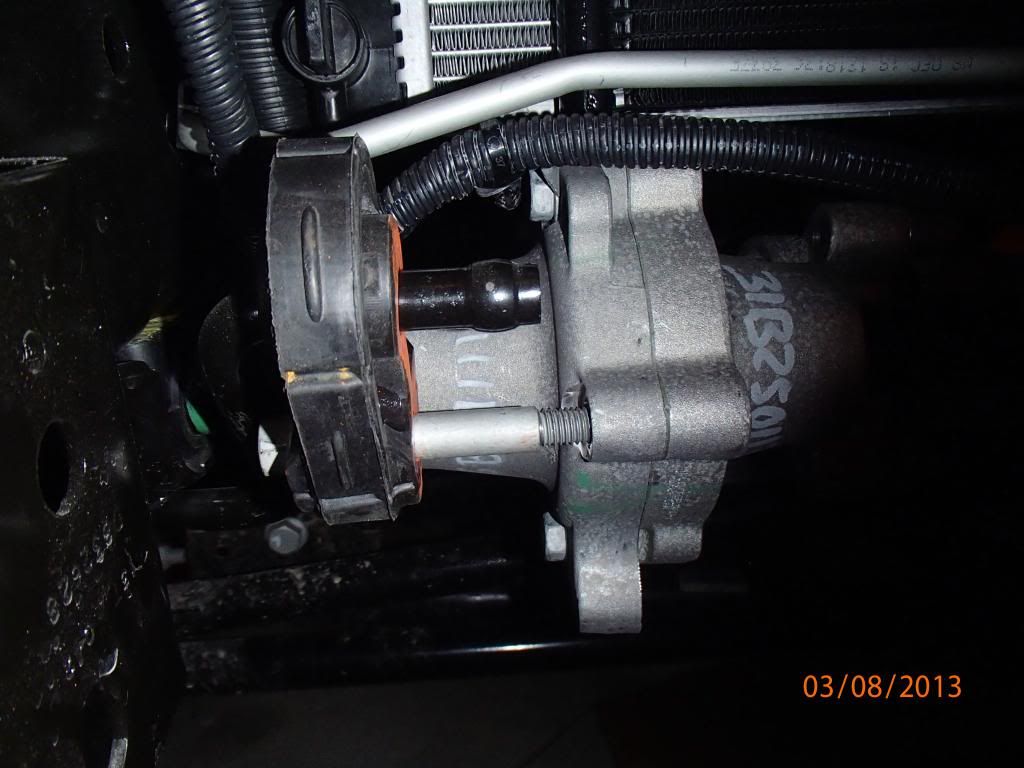

If you do have a rubicon, you will be required to relocate your sway bar motor. To do this you will disconnect the wiring and then unbolt the motor from the rubber mount securing it in place. Keep the bolt in the rubber sleeve, you will be reusing it as is.

Once unbolted, the sway bar motor will now spin freely. You will, if looking at the jeep from the passenger side, rotate the motor clockwise. Your factory mounting point will now be lower.

The next bolt, above the previous mounting bolt, will be your new mounting location. You will now remove this bolt.(I wished to save the bolt so you can now place this loose bolt into the original mounting place

To fully install the motor mounting bolt again in its new location, you will need to tap the new hole with a X" (I forget the size) drill. You will only want to go in 1/2" so measure the bit and mark it with tape as a stop point

In this image you can see the original location below.

With the first 1/2" of the new hole cleared, you can now secure the motor to the rubber mounting point

This is your original hole(for more clarity of what it should look like)

With the sway bar relocated, the rubicon models are now ready for the bumper to be installed. If you are installing a winch, now would be a good time to install it on the bumper while you have easier access to the mounting plate. I would also recommend re-installing your grill at this time, because the tolerances are very close(if installing a winch) and you may not be able to place the grill on after.

When installing the bumper I inserted two bolts, on each frame rail, backwards through the frame. This helps hold your two spacer plates in place, and guide the bumper as you mount it.

If you have a stinger or D-rings you will also install them at this time. Lastly you place all of your bolts with the nut on the inside the bumper and torque it down

That's it, you have now installed your EVO 1/4 pounder bumper and relocated your factory sway bar motor.

First you will want to remove the front grill to prevent possible damage. You must first disconnect the front turn signals. Slide the red tab away from the signal and then squeeze the release tab.

Next you will want to remove the upper and lower shrouds. The upper, has Philips headed plastic screw securing it. I have always had trouble removing these and I have found the trick of using a self tapping or drywall screw to help in removing these. They wont strip or become damaged by doing this so don't worry.

Next remove your factory fog lights. there are two ways of doing this. Either from the housing and pulling the bulb through like I did or by unplugging it.

The lower shroud is easy to remove from above(or start to remove) by using your screw driver to push the pin through

once everything is completed and dethatched from the bumper, you will now use an 18mm socket to unbolt the bumper from the frame

Next, if you have a 2012+ model Jeep, you will need to remove your vacuum pump. There are two hose attachments and an electrical connection that are easily located. One hose, you will press the green tab away from the connection and pull it directly out. The electrical connection plug has an easy squeeze and release point. Lastly the plain black hose. It is firmly in place and you just pull, very firmly, strait down.

With your pump removed you will now need to cut the pump bracket off. I made two vertical cuts right where the bracket meets the cross bar mount.

Next you will cut off your lower shroud attetchment bar/sway bar guard. These lines just perfectly cleared the bumpers lower edge.

The drivers side of the vehicle has room for moving tools around, but if you have a rubicon, the sway bar motor is tight, and cutting the passenger side rear bar off is difficult. I used the holes in the cross bar to place my pry bar and bend the rear remaining tab for easier cutting access.

If you have a non Rubicon model, Jeep is now ready for the bumper to be installed. I would take this time to clean up your exposed metal areas and paint them to prevent the certain rusting that will fallow otherwise. Also installing your chosen evap relocation kit(2012+ Jeeps) would be a good idea since you have clearance.

If you do have a rubicon, you will be required to relocate your sway bar motor. To do this you will disconnect the wiring and then unbolt the motor from the rubber mount securing it in place. Keep the bolt in the rubber sleeve, you will be reusing it as is.

Once unbolted, the sway bar motor will now spin freely. You will, if looking at the jeep from the passenger side, rotate the motor clockwise. Your factory mounting point will now be lower.

The next bolt, above the previous mounting bolt, will be your new mounting location. You will now remove this bolt.(I wished to save the bolt so you can now place this loose bolt into the original mounting place

To fully install the motor mounting bolt again in its new location, you will need to tap the new hole with a X" (I forget the size) drill. You will only want to go in 1/2" so measure the bit and mark it with tape as a stop point

In this image you can see the original location below.

With the first 1/2" of the new hole cleared, you can now secure the motor to the rubber mounting point

This is your original hole(for more clarity of what it should look like)

With the sway bar relocated, the rubicon models are now ready for the bumper to be installed. If you are installing a winch, now would be a good time to install it on the bumper while you have easier access to the mounting plate. I would also recommend re-installing your grill at this time, because the tolerances are very close(if installing a winch) and you may not be able to place the grill on after.

When installing the bumper I inserted two bolts, on each frame rail, backwards through the frame. This helps hold your two spacer plates in place, and guide the bumper as you mount it.

If you have a stinger or D-rings you will also install them at this time. Lastly you place all of your bolts with the nut on the inside the bumper and torque it down

That's it, you have now installed your EVO 1/4 pounder bumper and relocated your factory sway bar motor.

Trending Topics

#9

JK Enthusiast

Thread Starter

Join Date: Sep 2011

Location: USA

Posts: 429

Likes: 0

Received 0 Likes

on

0 Posts

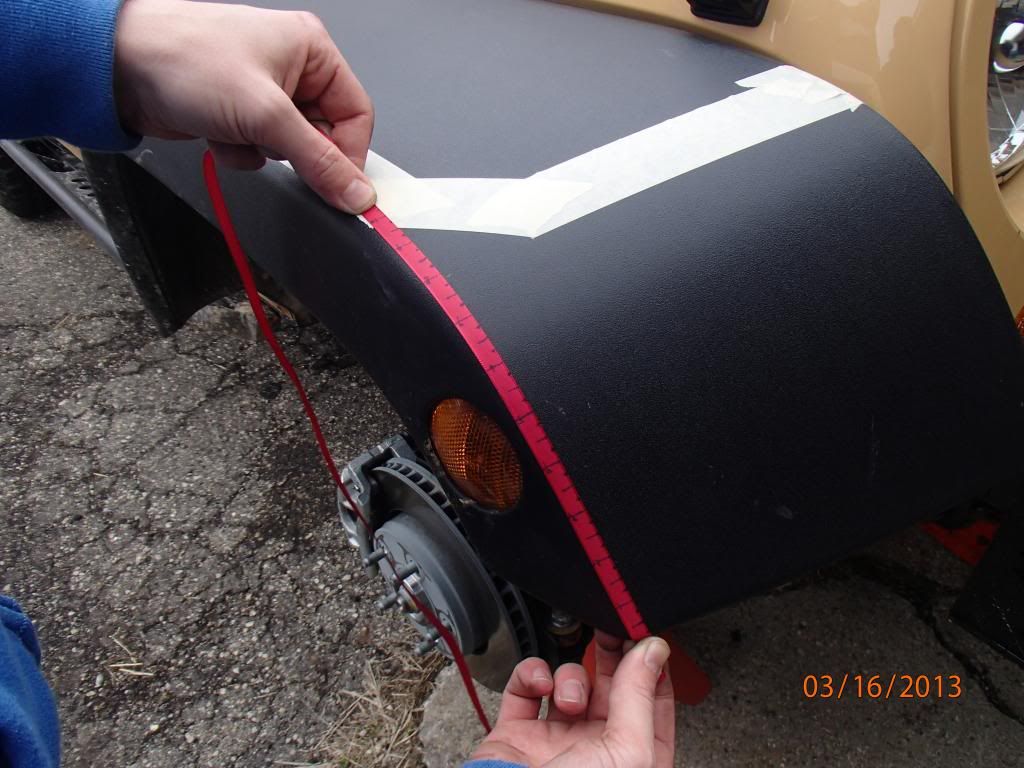

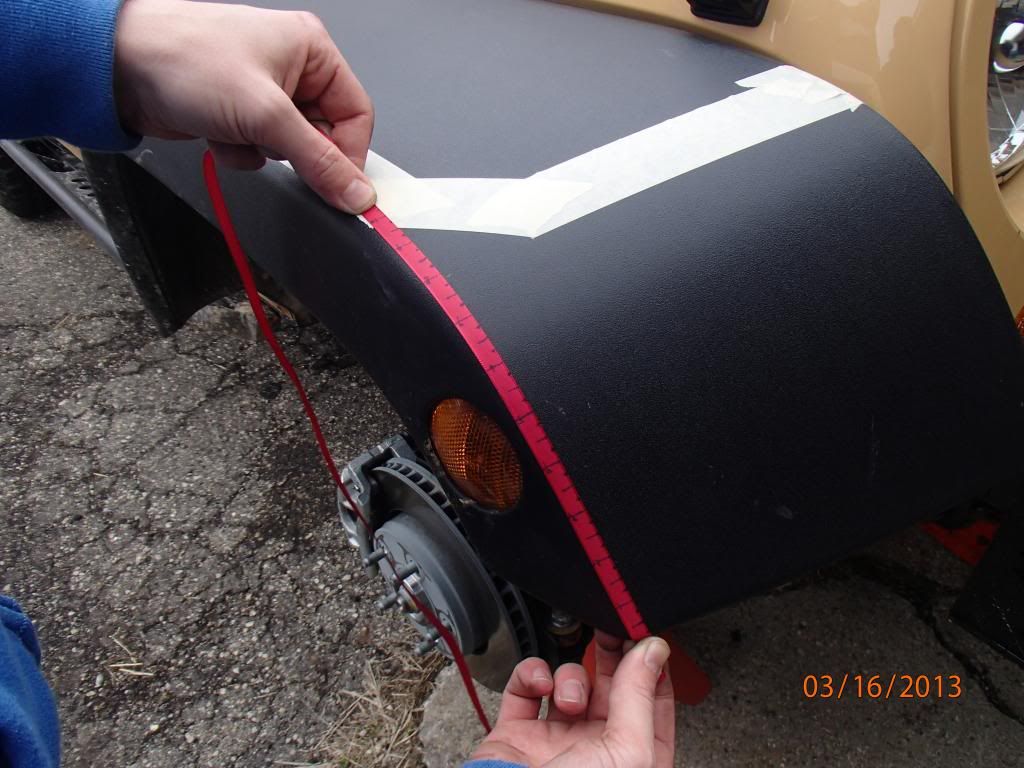

So while debating low COG and flat fenders I began to look at aftermarket flares. Well they are costly and I am cheap so to the cutting I went. I've seen quite a few fenders trimmed, but really liked this layout. So I taped off one side how i wanted the lines to look.

I then took measurements to be able to replicate on the other side

And then the cutting began. I started with a pneumatic saw from Harbor freight

But that was taking too long so I upgraded to a 3" cut off tool and that blew through the material!

After cutting the inner fender liners to line up to the fender-well

I then secured the liner to the fender-well with a zip tie

And this is the final product. I am debating on weather stripping/molding to give it a finished look

I then took measurements to be able to replicate on the other side

And then the cutting began. I started with a pneumatic saw from Harbor freight

But that was taking too long so I upgraded to a 3" cut off tool and that blew through the material!

After cutting the inner fender liners to line up to the fender-well

I then secured the liner to the fender-well with a zip tie

And this is the final product. I am debating on weather stripping/molding to give it a finished look