Turbocharging Tech: Better, Faster, and Even More Efficient

As with a lot of technology in the automobile, turbocharger technology is getting better. From finding ways to make a variable vane turbo, to spooling it without the need for exhaust flow, to even wilder things we just haven’t seen yet — turbos are going to get better, become faster, and be far more efficient than what we currently see. Here are a few ways your next turbocharged car will be better than your current one.

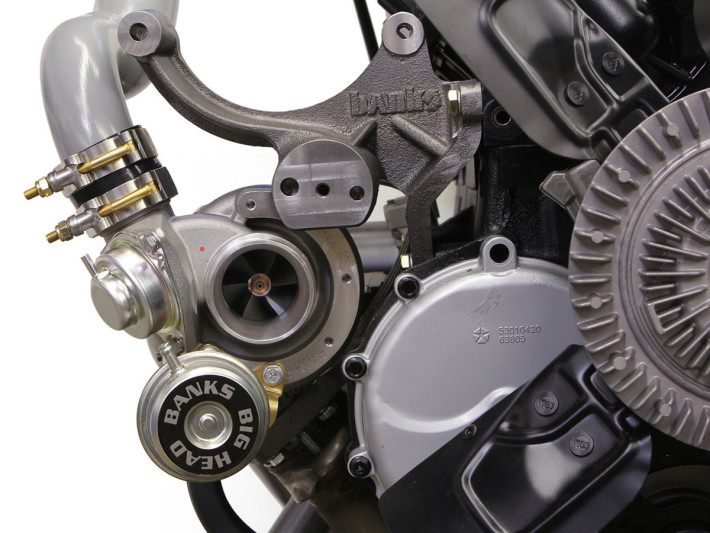

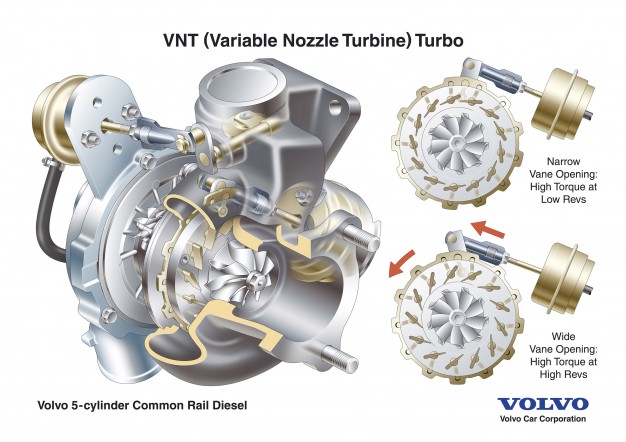

Variable Vane Technology

You’ll see it go by several different names, like VNT, VVT, VGT, and more, but variable vane technology is helping push a new breed of turbocharger. Gone are the days of huge amounts of boost lag or even the need for a pair of turbos on the same bank to overcome it. The way a variable vane turbo works is that at low RPM – where exhaust pressure is at its lowest – the vanes create a narrow passage way to artificially increase the pressure and spool the turbo. Once it hits the right RPM, the vanes open up and allow the faster gasses to flow out smoothly and keep building boost.

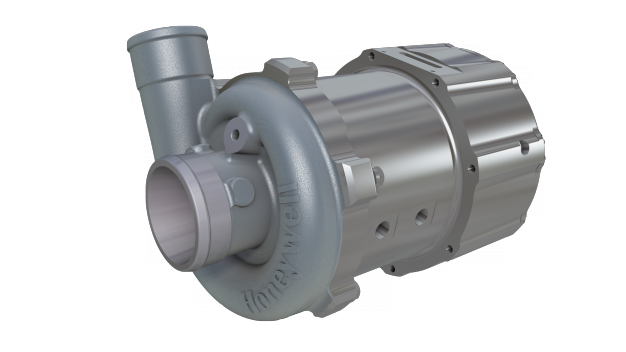

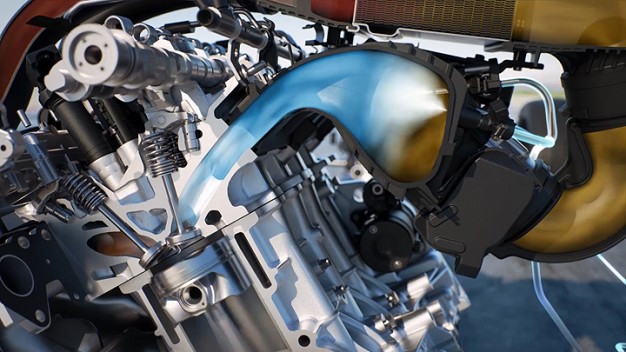

Electric Turbochargers and Hybrids

Once viewed as a joke among those in the turbocharging world, electric turbochargers are starting to get a far more serious look. This is thanks to new technology in electric motors and in energy storage. With thanks to Formula One tech with the MGU-H (Motor Generator Unit – Heat), we’re now seeing more efficient turbochargers getting a boost from electric motors when engine RPMs are low. Rather than using potentially harmful anti-lag that retards the ignition timing or uses some form of a pulse jet in the exhaust, we are starting to see motors used to spool a turbo at low RPMs. The motor also acts as a boost control; when the turbo begins to send more boost than needed, the motor goes into regeneration mode and slows down the spool to keep pressure in check.

The biggest problem we see in using a motor as a supercharging device, or even as a boost control, is the efficiency of the motor to what power it produces. For example, the Audi e-supercharger on the RS5 TDI concept used nine-horsepower to boost air. It also required a 48-volt battery system and auto makers aren’t in any hurry to get away from the 12-volt we currently use. However, with new battery and supercapacitor technologies, we may not even need that integrated into the current charging system at all. By utilizing the motor as a generator and as a power unit with a hybrid drivetrain that uses kinetic energy to harvest power while braking with a supercapacitor, we may not even need a 48-volt charging system.

It’s Coming

So these are coming to your future turbocharged car. How soon, well, that still mostly depends on how we get around the electronic side of the turbo, but variable vane technology is already here and starting to gain some steam in the aftermarket. That’s not nearly all, either, as there is work on how to use different intercooling techniques to reduce lag and power loss from too much intercooler piping, along with tried and true water/methanol injection. The future is bright, powerful, and looking better for turbos.