JK-Forum’s Scale Project Axial Jeep Wrangler Unlimited SCX10 Part 2.5

Before I step into the next update where I will be installing a new motor, I wanted to help you understand the why, what, and how of the scale RC motor. If you aren’t familiar with RC and are starting to look toward your first motor upgrade, this article will tell you about a few things that you will want to know, and what I will be doing in the next article.

When upgrading a crawler for more torque, it’s hard to figure out what you really need to do if you come from the 1:1 world. Motor windings, brush types, can sizing, mod vs. stock motors … there are so many new terms to learn, so here are a few things you need to know.

Stock vs. Mod Motor

We will be switching to a “mod motor” from our stock motor. This is also a class that has the timing locked in from the factory. Our mod motor will allow the timing to be changed and the motor to be serviced and modified.

Winding

When you see “12t” or “35t” or “15t Double” in the motor description, you’re seeing how many winds the motor has around its stator. The more winds, the more torque you’ll usually get out of the motor, but at the cost of a lower operating RPM. With a lower number, you’ll get more RPM, but higher RPM means lower torque.

Brushes

Because we’re sticking with a brushed motor for this project, brushes play an important role in the motor. These transmit the voltage the speed controller sends to the commutator. This is a wear item that also needs break-in time. Hard brushes wear longer and can give increased motor speed, but they can also cause premature commutator wear. Soft brushes tend to run quieter, but they can have a higher coefficient of friction.

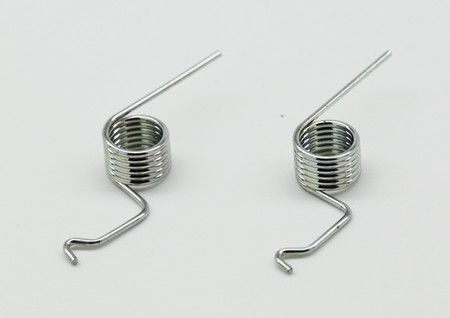

Springs

Brush springs hold the brushes against the commutator. The stronger the spring, the harder the brush will hold against the commutator. This also increases wear on the brushes and commutator. Stiff springs give great drag to the motor, which is good for downhill descents with a crawler.

Can

This is the outside of the motor, and it holds the magnets in. The can reflects the magnetic field of those magnets. As the magnetic field gets stronger, the motor will slow down if all else is kept the same.