Brake Tech: Pad Types and How they Affect Your Stopping Performance

When you deal with modern disc brakes, you get several options on pad friction material types and how they affect brake performance of your JK Wrangler. In this article we’ll take a look at some of the more popular friction materials and how they affect brake performance, dust, and noise. We’ll also look into the two types of ways to hold the friction material to the backing plate.

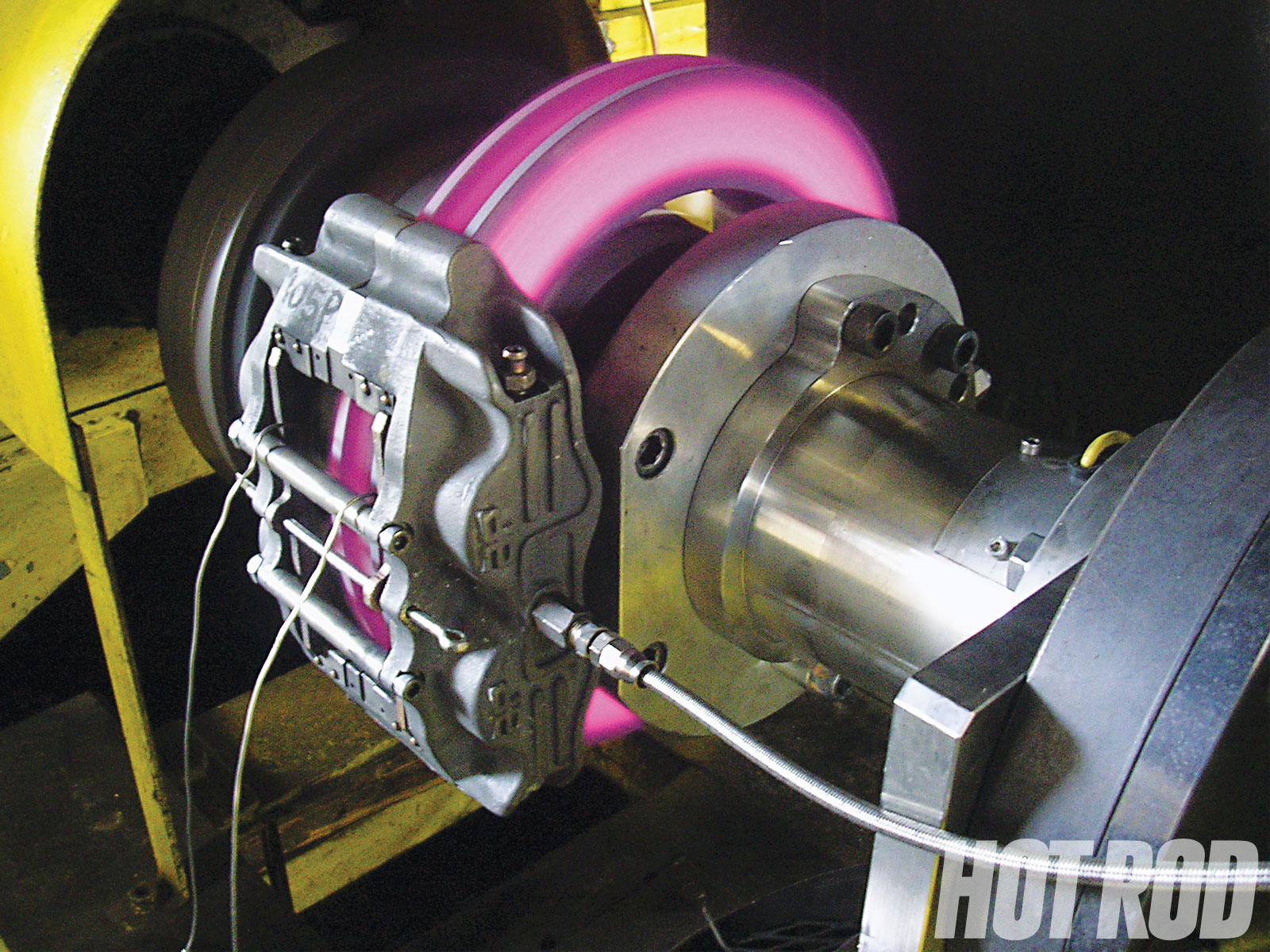

First, what is the purpose of the brake system and how does it work? Your brakes are the force behind stopping your JK before you slam into that idiot talking on their cell phone. When you hit the brake pedal, you begin the process of taking kinetic energy of your wheels and turning it into a force that uses friction and converts it into heat. The pad material pushing against your rotors is that friction.

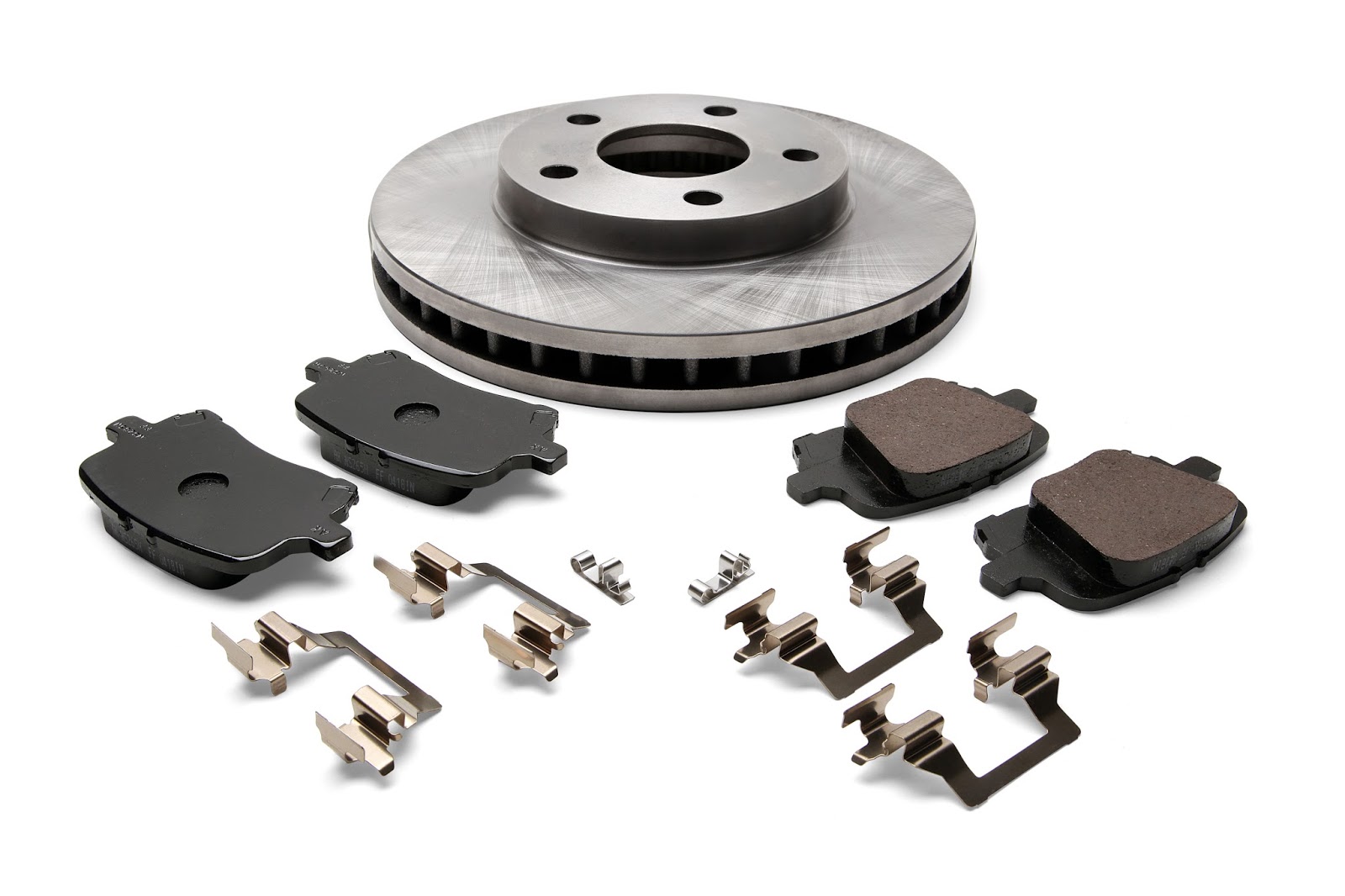

A brake pad is made up of two parts, not including any wear sensors. It is the backing plate and the friction material. The friction material is attached to the backing plate by either riveting or bonding. Riveting the material to the backing plate means that you will hit the rivets at a point. Bonding is the more popular form as it does give you more friction material to use. The bonding is a type of adhesive that does give off a vapor that can interfere with braking performance if overheated and can be a cause for brake fade.

There are three types of materials typically found in a steel rotor brake. There are other materials but they are exotic like Carbon-Ceramic and full Carbon systems. The four types of typical materials are Semi-Metallic, Organic, Low-Metallic, and Ceramic. Semi-Metallic brake pads are about 30 to 60-percent metal with other mixtures within the friction material. It is a very good material to look for if you do lots of braking, but it can be harsh on rotors and may not perform well in very cold temperatures as they won’ t put out enough friction to make any heat.

Organic pads are made of materials such as fiber, chopped glass, mineral fibers, and even Kevlar mixtures. Organic pads are usually low-dust and low-noise, and are generally better on the rotors, but they do tend to wear out fast. They are also not good for brake environments that see a lot of heat. We will include the Low-Metallic NAO pads you see as they don’t contain steel, but contain a lot of the same organic formula with more copper or steel. So, these pads will be a little noisier compared to full-organic, but not as much as semi-metallic.

Finally, there is the ceramic brake pad. It is a pad that uses ceramic compounds along with some other metals in its mixture; typically copper. They provide the lowest dust and noise and have the lowest wear on the brake rotors, but can take heat and stop your JK nearly as well as the semi-metallic pad. A quick word of caution: with any brake pad change, be sure you resurface your rotors or replace them. Be sure to bed them after installation to ensure the best performance and longest life.

Make a stop over at the forum. >>

images [Hot Rod]